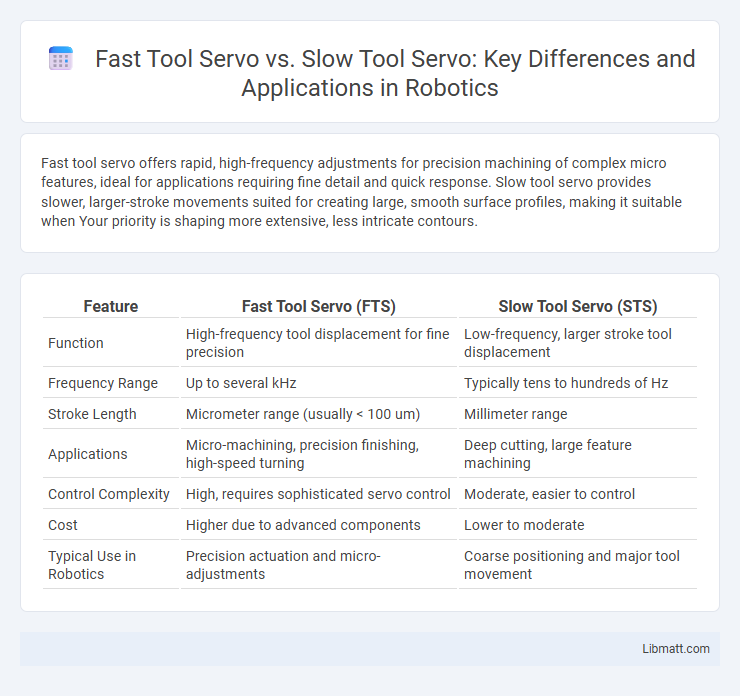

Fast tool servo offers rapid, high-frequency adjustments for precision machining of complex micro features, ideal for applications requiring fine detail and quick response. Slow tool servo provides slower, larger-stroke movements suited for creating large, smooth surface profiles, making it suitable when Your priority is shaping more extensive, less intricate contours.

Table of Comparison

| Feature | Fast Tool Servo (FTS) | Slow Tool Servo (STS) |

|---|---|---|

| Function | High-frequency tool displacement for fine precision | Low-frequency, larger stroke tool displacement |

| Frequency Range | Up to several kHz | Typically tens to hundreds of Hz |

| Stroke Length | Micrometer range (usually < 100 um) | Millimeter range |

| Applications | Micro-machining, precision finishing, high-speed turning | Deep cutting, large feature machining |

| Control Complexity | High, requires sophisticated servo control | Moderate, easier to control |

| Cost | Higher due to advanced components | Lower to moderate |

| Typical Use in Robotics | Precision actuation and micro-adjustments | Coarse positioning and major tool movement |

Introduction to Fast Tool Servo and Slow Tool Servo

Fast Tool Servo (FTS) and Slow Tool Servo (STS) are advanced machining technologies used in precision turning applications to create complex surface geometries. FTS operates at high frequencies, enabling rapid tool movements for fine and high-speed corrections, ideal for micro-structuring and high-precision tasks. STS functions at lower speeds with larger strokes, providing smooth, gradual tool adjustments suited for larger form corrections and contours.

Fundamental Differences Between FTS and STS

Fast Tool Servo (FTS) uses high-frequency actuation to achieve rapid, small-scale tool movements suitable for ultra-precise, high-speed machining, while Slow Tool Servo (STS) operates at lower frequencies with larger stroke capabilities for shaping complex geometries. FTS excels in applications requiring rapid modulation of the cutting tool's position, enhancing surface finish and form accuracy, whereas STS offers greater displacement range but slower response suitable for macro-scale contouring. Understanding these fundamental differences enables you to select the appropriate servo mechanism based on precision and stroke requirements in CNC machining tasks.

Working Principles of Fast Tool Servo

Fast tool servo (FTS) operates by rapidly oscillating the cutting tool to make precise, high-frequency movements on the workpiece surface, enabling fine texture and micro-geometry machining. In contrast, slow tool servo (STS) adjusts tool position slowly and is primarily used for larger, less complex surface profiles. Your choice between FTS and STS depends on the required machining precision and application speed, with FTS excelling in dynamic, high-resolution tasks.

Working Principles of Slow Tool Servo

The Slow Tool Servo (STS) operates by oscillating the cutting tool along the Z-axis at a slow frequency to create precise, variable-depth features on a workpiece during turning processes. This controlled tool displacement allows for intricate surface texturing, such as micro-grooves or lens profiles, without altering the spindle speed. Its primary advantage is the ability to produce complex axial profiles with high accuracy and surface finish compared to conventional CNC turning or rapid tool servos.

Key Applications of Fast Tool Servo

Fast Tool Servo (FTS) technology excels in high-precision manufacturing applications requiring rapid, fine modulation of cutting tools, such as micro-lens fabrication, high-frequency communication components, and aerospace part machining. FTS enables ultra-fast surface generation on complex geometries, providing enhanced accuracy and production speed compared to Slow Tool Servo (STS) systems, which are better suited for larger, less time-sensitive shapes. Your choice of FTS ensures improved part quality and efficiency in industries where intricate, high-speed tool adjustments are critical.

Key Applications of Slow Tool Servo

Slow Tool Servo (STS) technology is predominantly used in applications requiring precise micro-machining, such as the production of complex aspherical lenses, optical components, and high-precision automotive parts. Its ability to generate fine surface structures and intricate geometries makes it ideal for aerospace component manufacturing and microfluidic devices. STS excels in creating variable depths and smooth surface finishes, distinguishing it from Fast Tool Servo (FTS) technologies which target high-frequency, small-amplitude modulations.

Comparative Performance Analysis: FTS vs STS

Fast Tool Servo (FTS) systems offer high-frequency, small-stroke movements ideal for precision machining of micro-features, enabling rapid surface modulation with nanometer accuracy. Slow Tool Servo (STS) systems provide larger stroke capabilities but operate at lower frequencies, making them suitable for machining complex macro-geometries and tapering profiles with slower response times. In comparative performance analysis, FTS excels in high-speed, fine-detail applications requiring minimal tool inertia, while STS is better suited for tasks demanding significant tool travel and adaptability to varied part geometries.

Precision and Accuracy: FTS vs STS

Fast tool servo (FTS) offers higher precision and accuracy for intricate micro-machining tasks due to its rapid, fine adjustments in tool positioning, achieving sub-micron resolution. Slow tool servo (STS), while capable of handling larger, complex surface profiles, typically provides lower precision as it relies on slower, less responsive movements. Your choice between FTS and STS should consider the balance between the required machining accuracy and the complexity of the part geometry.

Cost Considerations and Implementation Challenges

Fast tool servo systems generally involve higher initial costs due to precision actuation components and advanced control electronics, whereas slow tool servo options present lower upfront expenses but may require more complex mechanical integration. Implementation challenges for fast tool servos include achieving high-frequency responsiveness and minimizing tool wear, while slow tool servos face difficulties in maintaining accuracy over larger motion ranges and slower dynamic response. Cost considerations should balance the system's intended application speed, precision requirements, and long-term maintenance expenses to determine the optimal servo technology.

Choosing the Right Tool Servo for Your Needs

Fast tool servo offers precise, high-frequency adjustments ideal for applications requiring fine, rapid surface modifications, enhancing accuracy and efficiency. Slow tool servo, meanwhile, excels in handling larger tool motions with longer stroke lengths, suitable for creating complex contours or deeper cuts. Understanding your machining requirements and workpiece characteristics ensures you select the tool servo that optimizes performance and meets your production goals.

Fast tool servo vs Slow tool servo Infographic

libmatt.com

libmatt.com