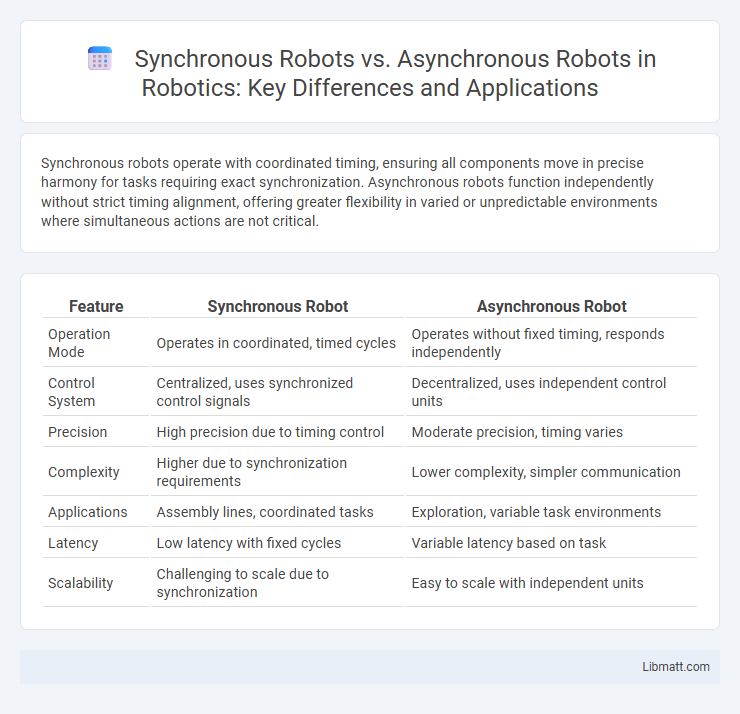

Synchronous robots operate with coordinated timing, ensuring all components move in precise harmony for tasks requiring exact synchronization. Asynchronous robots function independently without strict timing alignment, offering greater flexibility in varied or unpredictable environments where simultaneous actions are not critical.

Table of Comparison

| Feature | Synchronous Robot | Asynchronous Robot |

|---|---|---|

| Operation Mode | Operates in coordinated, timed cycles | Operates without fixed timing, responds independently |

| Control System | Centralized, uses synchronized control signals | Decentralized, uses independent control units |

| Precision | High precision due to timing control | Moderate precision, timing varies |

| Complexity | Higher due to synchronization requirements | Lower complexity, simpler communication |

| Applications | Assembly lines, coordinated tasks | Exploration, variable task environments |

| Latency | Low latency with fixed cycles | Variable latency based on task |

| Scalability | Challenging to scale due to synchronization | Easy to scale with independent units |

Introduction: Understanding Synchronous and Asynchronous Robots

Synchronous robots operate using coordinated, real-time control signals that ensure precise timing and movement synchronization, ideal for applications requiring exact positioning and speed alignment. Asynchronous robots function independently without synchronized timing, allowing more flexible and adaptive operations but potentially less precision in coordinated tasks. The choice between synchronous and asynchronous robots depends on the specific requirements for timing accuracy, flexibility, and control complexity in industrial automation systems.

Definition and Core Concepts

Synchronous robots operate with actuators that move in a coordinated fashion, driven by a shared clock signal to maintain precise timing and synchronization, essential for applications requiring exact positioning and timing control. Asynchronous robots utilize independently controlled actuators without a common clock, allowing more flexibility but potentially sacrificing precise coordination, making them suitable for tasks with less stringent timing demands. Your selection between synchronous and asynchronous robots depends on the required level of motion accuracy and application-specific synchronization needs.

Key Differences Between Synchronous and Asynchronous Robots

Synchronous robots operate with precise, real-time coordination of their components, enabling accurate and predictable movements ideal for tasks requiring high synchronization. Asynchronous robots function independently with less coordination, offering flexibility and easier implementation in less time-critical applications. Your choice between these robots depends on the required precision, speed, and complexity of the robotic system's tasks.

Communication Models in Robotics

Synchronous robots operate using time-coordinated communication models where actions and data exchanges occur in fixed, predictable cycles, ensuring precise coordination and real-time control. Asynchronous robots rely on event-driven communication models that enable components to transmit and receive data independently without strict timing constraints, allowing for greater flexibility and scalability in distributed systems. The choice between synchronous and asynchronous communication models directly impacts latency, fault tolerance, and system responsiveness in robotic applications.

Task Coordination and Execution

Synchronous robots perform tasks with tightly coordinated timing, ensuring precise joint movements and seamless collaboration in applications requiring exact synchronization, such as assembly lines and pick-and-place operations. Asynchronous robots operate independently with flexible timing, allowing them to handle tasks that involve intermittent or variable execution rates, making them suitable for processes like inspection or material handling where strict timing is less critical. The choice between synchronous and asynchronous robots directly impacts efficiency, precision, and adaptability in robotic task coordination and execution.

Performance and Efficiency Comparisons

Synchronous robots typically offer higher performance and precision due to their ability to coordinate movements in real time, resulting in smoother and more accurate operations. Asynchronous robots, while generally simpler and less costly, tend to have lower efficiency and can exhibit delays or lag in response times because their movements are not continuously synchronized. Choosing the right option depends on Your need for speed, accuracy, and overall system complexity, with synchronous robots being preferable for demanding, high-precision tasks.

Applications: When to Use Synchronous vs Asynchronous Robots

Synchronous robots excel in applications requiring precise coordination and real-time communication, such as assembly lines, robotic surgery, and collaborative manufacturing where timing accuracy ensures safety and efficiency. Asynchronous robots are suited for tasks with more flexibility in timing, like warehouse automation, material handling, and inspection, where independent operation and tolerance for communication delays reduce system complexity. Selecting between synchronous and asynchronous robots depends on the need for tight synchronization versus tolerant, scalable automation in dynamic industrial environments.

Challenges and Limitations

Synchronous robots face challenges related to precise timing and synchronization requirements, which can lead to increased complexity in control systems and higher costs. Asynchronous robots encounter limitations due to potential latency and lack of coordinated movement, resulting in reduced efficiency and difficulty in tasks requiring tight collaboration. Both types can experience integration issues with other automated systems, impacting overall operational fluidity.

Future Trends in Robotic Synchronization

Future trends in robotic synchronization emphasize the integration of advanced AI algorithms to enhance synchronous robot coordination, enabling real-time adaptive responses in complex environments. Asynchronous robots benefit from improved communication protocols and decentralized control systems, promoting scalability and fault tolerance in multi-robot applications. Emerging developments include hybrid synchronization models that combine synchronous precision with asynchronous flexibility, driving efficiency in industrial automation and collaborative robotics.

Conclusion: Choosing the Right Approach for Your Needs

Synchronous robots offer precise coordination and timing, ideal for complex tasks requiring high accuracy and real-time responsiveness, while asynchronous robots provide greater flexibility and scalability for less time-sensitive operations. Selecting the right robot depends on specific application requirements, such as task complexity, speed, and synchronization needs. Evaluating these factors ensures optimal performance and cost-efficiency in automation solutions.

Synchronous robot vs Asynchronous robot Infographic

libmatt.com

libmatt.com