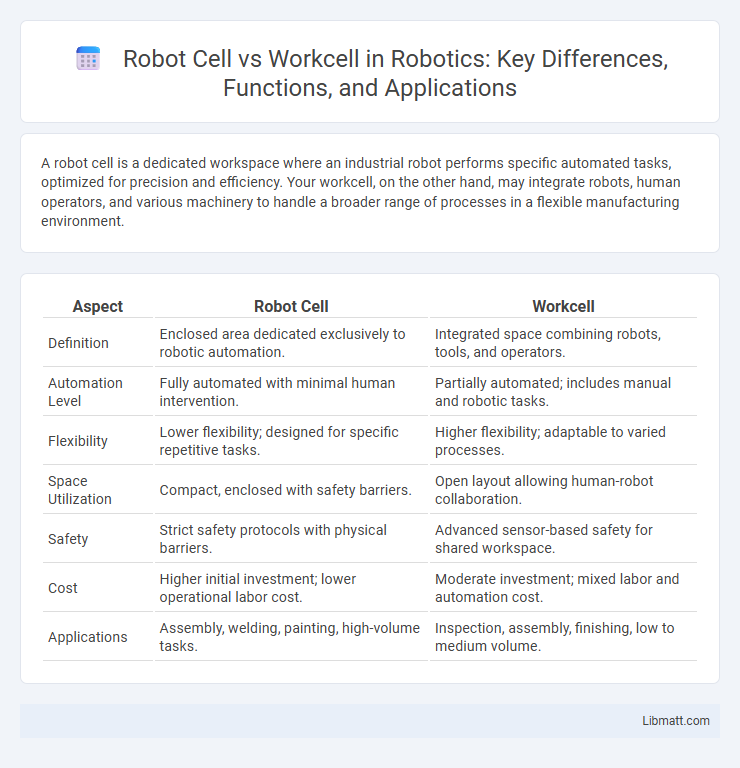

A robot cell is a dedicated workspace where an industrial robot performs specific automated tasks, optimized for precision and efficiency. Your workcell, on the other hand, may integrate robots, human operators, and various machinery to handle a broader range of processes in a flexible manufacturing environment.

Table of Comparison

| Aspect | Robot Cell | Workcell |

|---|---|---|

| Definition | Enclosed area dedicated exclusively to robotic automation. | Integrated space combining robots, tools, and operators. |

| Automation Level | Fully automated with minimal human intervention. | Partially automated; includes manual and robotic tasks. |

| Flexibility | Lower flexibility; designed for specific repetitive tasks. | Higher flexibility; adaptable to varied processes. |

| Space Utilization | Compact, enclosed with safety barriers. | Open layout allowing human-robot collaboration. |

| Safety | Strict safety protocols with physical barriers. | Advanced sensor-based safety for shared workspace. |

| Cost | Higher initial investment; lower operational labor cost. | Moderate investment; mixed labor and automation cost. |

| Applications | Assembly, welding, painting, high-volume tasks. | Inspection, assembly, finishing, low to medium volume. |

Understanding Robot Cells and Workcells

Robot cells are specialized areas designed to house one or more robots performing automated tasks, offering precise control and safety features tailored to robotic operations. Workcells encompass a broader concept, integrating various equipment, tools, and operators to complete a specific manufacturing or assembly process efficiently. Understanding the distinction helps optimize your production line by aligning automation capabilities with workflow flexibility and human involvement.

Key Differences Between Robot Cells and Workcells

Robot cells are automated setups primarily designed for specific robotic tasks, often enclosed for safety and efficiency, whereas workcells integrate both manual labor and machinery to optimize workflow and productivity. Robot cells emphasize precision and repeatability in industrial automation, while workcells focus on flexibility and collaboration between humans and machines. Understanding these key differences helps you choose the ideal configuration to enhance manufacturing processes and operational efficiency.

Core Components of a Robot Cell

A Robot Cell typically consists of a robotic arm, end-of-arm tooling (EOAT), a controller, and safety enclosures designed to automate specific tasks with precision and repeatability. In comparison, a Workcell encompasses not only these robot elements but also integrated fixtures, conveyors, sensors, and human-machine interfaces to facilitate more complex, collaborative workflows. The core components of a Robot Cell emphasize robotic actuation and control systems, whereas a Workcell integrates additional material handling and process components for enhanced operational flexibility.

Essential Elements of a Workcell

A workcell comprises essential elements such as dedicated machinery, human operators, and a defined workflow designed to optimize productivity and minimize waste. In contrast, a robot cell specifically integrates robotic arms with automation controls to perform repetitive tasks with high precision and efficiency. Workcells emphasize flexibility and human-robot collaboration, while robot cells focus primarily on automation and speed within manufacturing processes.

Applications for Robot Cells in Manufacturing

Robot cells enhance manufacturing efficiency by automating repetitive tasks such as welding, painting, assembly, and material handling with high precision. These cells integrate robotic arms, sensors, and control systems to perform complex operations in automotive, electronics, and metal fabrication industries. Robot cells improve production speed, reduce human error, and ensure consistent product quality, making them ideal for mass production environments.

Typical Uses of Workcells in Industry

Workcells in industry are typically designed for flexible assembly, parts handling, and quality inspection tasks where human intervention is essential alongside automated processes. They often integrate various machines and manual workstations to optimize workflow efficiency and adaptability in small to medium production batches. These setups enable rapid changeovers and customization, making them ideal for industries like electronics manufacturing, automotive subassembly, and consumer goods assembly.

Advantages of Robot Cells

Robot cells offer significant advantages over traditional workcells by providing enhanced precision, repeatability, and speed in manufacturing processes. They improve operational efficiency through automated handling and integrated sensors, reducing human error and increasing safety in hazardous environments. This leads to higher output quality, consistent production rates, and scalability in industrial applications.

Benefits of Workcells

Workcells enhance manufacturing efficiency by integrating multiple processes within a single, flexible layout, leading to reduced material handling and shorter cycle times. They improve operator ergonomics and collaboration, fostering higher quality output and easier customization compared to isolated robot cells. This approach supports lean manufacturing principles by minimizing waste and enabling rapid changeovers, ultimately boosting productivity and cost-effectiveness.

Selecting Between Robot Cell and Workcell

Selecting between a robot cell and a workcell depends on the complexity and flexibility of the tasks involved. Robot cells, typically enclosed and dedicated to specific automation tasks, offer high precision and consistency ideal for repetitive processes such as welding or assembly. Workcells provide greater versatility and human-robot collaboration, supporting a variety of operations and adjustments, suitable for mixed tasks and changing production demands.

Future Trends in Robotic Automation Systems

Robot cells and workcells are evolving with advanced integration of artificial intelligence, machine learning, and IoT connectivity, enhancing autonomous decision-making and real-time data analytics. The trend towards flexible, modular robotic automation systems allows seamless scalability and adaptation to diverse manufacturing workflows, promoting increased productivity and cost efficiency. Collaborative robots (cobots) within workcells facilitate safer human-robot interaction, supporting more dynamic and adaptable production environments in Industry 4.0 ecosystems.

Robot Cell vs Workcell Infographic

libmatt.com

libmatt.com