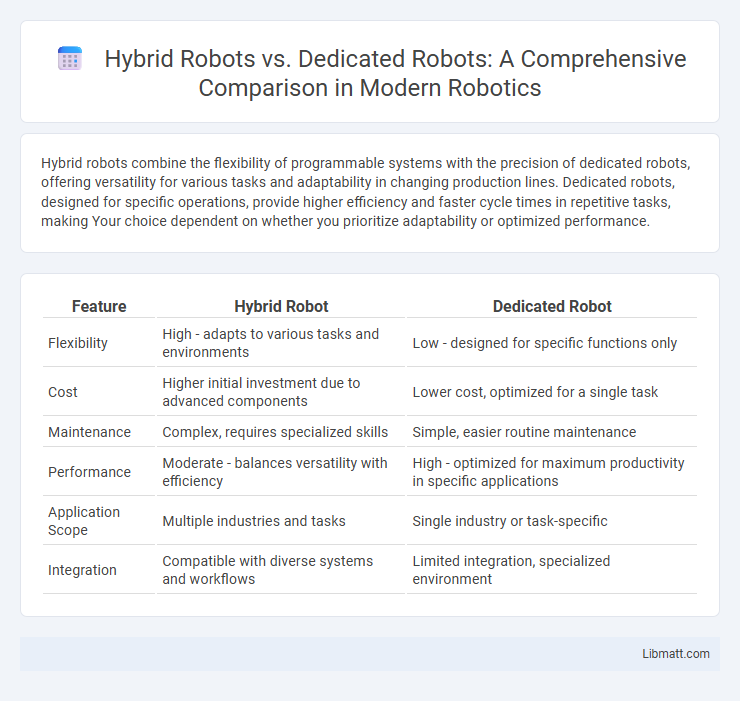

Hybrid robots combine the flexibility of programmable systems with the precision of dedicated robots, offering versatility for various tasks and adaptability in changing production lines. Dedicated robots, designed for specific operations, provide higher efficiency and faster cycle times in repetitive tasks, making Your choice dependent on whether you prioritize adaptability or optimized performance.

Table of Comparison

| Feature | Hybrid Robot | Dedicated Robot |

|---|---|---|

| Flexibility | High - adapts to various tasks and environments | Low - designed for specific functions only |

| Cost | Higher initial investment due to advanced components | Lower cost, optimized for a single task |

| Maintenance | Complex, requires specialized skills | Simple, easier routine maintenance |

| Performance | Moderate - balances versatility with efficiency | High - optimized for maximum productivity in specific applications |

| Application Scope | Multiple industries and tasks | Single industry or task-specific |

| Integration | Compatible with diverse systems and workflows | Limited integration, specialized environment |

Introduction to Hybrid and Dedicated Robots

Hybrid robots combine the flexibility of dedicated robots with the adaptability of general-purpose machines, enabling versatile automation across multiple tasks. Dedicated robots are specially designed for specific applications, offering high efficiency and precision in repetitive processes. Your choice depends on the need for customization versus specialized performance in industrial automation.

Key Differences Between Hybrid and Dedicated Robots

Hybrid robots combine the flexibility of programmable robots with the speed and precision of dedicated robots, making them ideal for tasks requiring adaptability and high throughput. Dedicated robots are optimized for specific repetitive tasks, providing maximum efficiency, accuracy, and durability in fixed applications. Understanding these key differences helps you choose the right robotic solution based on your production needs and operational requirements.

Core Principles of Hybrid Robot Design

Hybrid robot design integrates the flexibility of programmable systems with the efficiency of dedicated robotic mechanisms, leveraging both software adaptability and specialized hardware components. Core principles include modularity to enable easy reconfiguration, sensor fusion for enhanced environmental interaction, and adaptive control algorithms that optimize performance across varied tasks. Your operational efficiency benefits from the hybrid approach by combining precision, speed, and versatility in dynamic production environments.

Advantages of Dedicated Robots

Dedicated robots provide superior precision and consistency in specialized tasks due to their optimized design and programming for specific applications. Their simplified architecture allows for easier maintenance and higher reliability compared to hybrid robots with complex multi-function capabilities. Industries benefit from dedicated robots through increased productivity and lower overall operational costs, especially in repetitive, high-volume manufacturing processes.

Flexibility and Adaptability in Hybrid Robots

Hybrid robots offer superior flexibility and adaptability by combining the strengths of dedicated robots with reprogrammable systems, enabling them to perform diverse tasks across various applications. Their ability to switch between functions without extensive reconfiguration enhances operational efficiency and reduces downtime in dynamic manufacturing environments. Your production line can benefit from hybrid robots' versatile capabilities, adapting swiftly to changing demands and complex processes.

Performance Metrics: Hybrid vs Dedicated Robots

Hybrid robots combine the versatility of multiple functions with moderate speed and precision, making them suitable for varied tasks but often at the cost of specialized performance. Dedicated robots excel in specific operations, delivering higher accuracy, faster cycle times, and greater repeatability due to optimized design for singular applications. Your choice between hybrid and dedicated robots should consider performance metrics such as payload capacity, cycle time, precision, and flexibility to match your operational demands.

Cost Efficiency and Investment Considerations

Hybrid robots offer cost efficiency by combining the flexibility of dedicated robots with the adaptability of general-purpose machines, reducing the need for multiple specialized units and lowering overall investment. Dedicated robots require higher upfront capital for each specialized task but deliver optimized performance and lower operational costs in large-scale, repetitive processes. Evaluating production volume, task complexity, and long-term scalability is essential to balance initial investment with ongoing expense and ROI.

Application Scenarios: Where Each Robot Excels

Hybrid robots excel in environments requiring flexibility and adaptability, such as assembly lines with varying tasks or custom manufacturing processes, where You benefit from their ability to switch functions seamlessly. Dedicated robots are optimal for high-volume, repetitive tasks like packaging or welding, offering superior speed and precision in specific applications. Both robots enhance productivity, but selecting the right one depends on whether your operation demands versatility or specialization.

Challenges and Limitations of Each Robot Type

Hybrid robots face challenges like complex control systems and integration difficulties due to their multifunctional design, while dedicated robots are limited by inflexibility, as they perform only specific tasks efficiently. Hybrid systems often require advanced programming and maintenance, which can increase operational costs and downtime. Your choice depends on balancing the flexibility of hybrid robots against the high efficiency but restricted versatility of dedicated robots.

Future Trends in Robotic Automation

Hybrid robots combine the flexibility of dedicated robots with multifunctional capabilities, enabling seamless adaptation to various tasks in evolving industrial environments. Future trends in robotic automation emphasize increased AI integration, enhanced sensory feedback, and collaborative human-robot interaction to boost efficiency and precision. Your manufacturing processes can benefit from hybrid robots by embracing these advancements to optimize productivity and reduce downtime.

Hybrid robot vs Dedicated robot Infographic

libmatt.com

libmatt.com