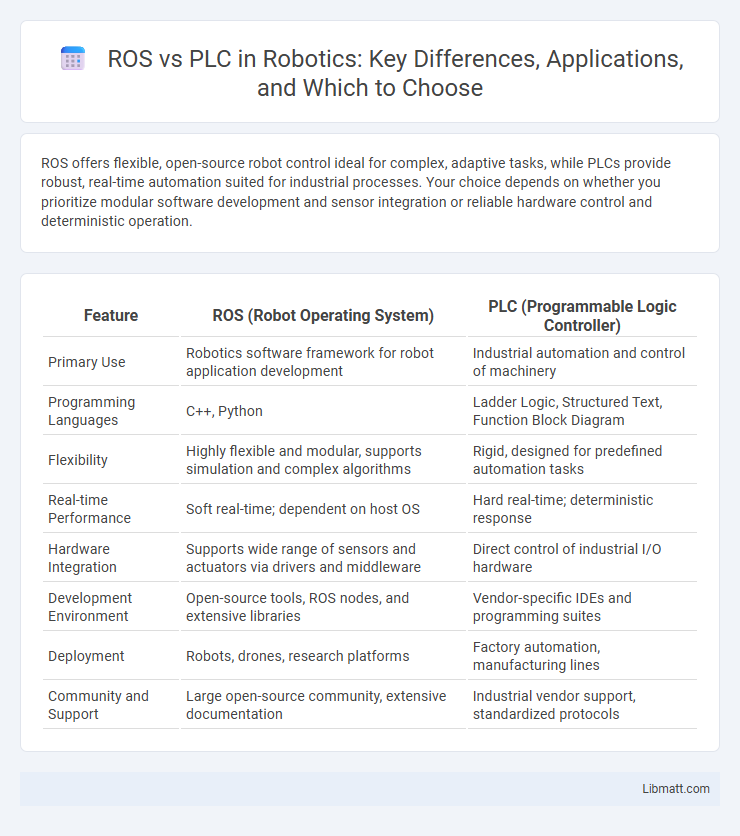

ROS offers flexible, open-source robot control ideal for complex, adaptive tasks, while PLCs provide robust, real-time automation suited for industrial processes. Your choice depends on whether you prioritize modular software development and sensor integration or reliable hardware control and deterministic operation.

Table of Comparison

| Feature | ROS (Robot Operating System) | PLC (Programmable Logic Controller) |

|---|---|---|

| Primary Use | Robotics software framework for robot application development | Industrial automation and control of machinery |

| Programming Languages | C++, Python | Ladder Logic, Structured Text, Function Block Diagram |

| Flexibility | Highly flexible and modular, supports simulation and complex algorithms | Rigid, designed for predefined automation tasks |

| Real-time Performance | Soft real-time; dependent on host OS | Hard real-time; deterministic response |

| Hardware Integration | Supports wide range of sensors and actuators via drivers and middleware | Direct control of industrial I/O hardware |

| Development Environment | Open-source tools, ROS nodes, and extensive libraries | Vendor-specific IDEs and programming suites |

| Deployment | Robots, drones, research platforms | Factory automation, manufacturing lines |

| Community and Support | Large open-source community, extensive documentation | Industrial vendor support, standardized protocols |

Introduction to ROS and PLC

Robot Operating System (ROS) is an open-source middleware framework designed to support software development for robotics, offering tools and libraries for sensor integration, control, and communication. Programmable Logic Controllers (PLCs) are industrial digital computers specialized in automating electromechanical processes through real-time control and programmable inputs/outputs. While ROS provides flexibility for complex robotic systems and research environments, PLCs prioritize robustness, reliability, and deterministic behavior in industrial automation settings.

Key Differences Between ROS and PLC

ROS (Robot Operating System) serves as a flexible, open-source middleware providing tools and libraries for robot software development, while PLC (Programmable Logic Controller) is a dedicated industrial computer designed for real-time automation tasks. ROS emphasizes modularity, scalability, and integration with various sensors and algorithms, supporting complex robotic systems, whereas PLCs prioritize reliability, deterministic control, and robustness in harsh industrial environments. The core difference lies in ROS's software-driven approach aimed at research and development versus PLC's hardware-centric design tailored for precise, repetitive control operations in manufacturing processes.

Architecture Overview: ROS vs PLC

ROS (Robot Operating System) features a modular, distributed architecture designed for flexible, scalable robot software development, enabling integration of various sensors, actuators, and algorithms through nodes and topics. PLC (Programmable Logic Controller) architecture relies on a centralized, deterministic control system optimized for real-time industrial automation tasks with specific input/output modules and a fixed scanning cycle. Your choice between ROS and PLC should consider the need for open-source extensibility versus robust, real-time process control in industrial environments.

Programming Languages and Flexibility

ROS supports multiple programming languages such as Python and C++, providing high flexibility for custom robotics applications and complex algorithms. PLCs primarily use ladder logic or structured text, optimized for real-time industrial automation but less adaptable to diverse programming paradigms. Your choice depends on whether you require broad programming versatility with ROS or the specialized, deterministic control offered by PLCs.

Real-Time Performance Comparison

ROS (Robot Operating System) often faces challenges in achieving strict real-time performance due to its general-purpose middleware design, while PLCs (Programmable Logic Controllers) are specifically engineered for deterministic and high-reliability real-time control in industrial settings. PLCs execute tasks within precise timing constraints, ensuring consistent response times critical for safety and automation processes, whereas ROS is more flexible but may introduce latency and jitter due to operating system and communication overhead. When your application demands guaranteed real-time performance and minimal latency, PLCs typically outperform ROS in deterministic control execution.

Scalability and Integration

ROS offers greater scalability by supporting distributed robotic systems across multiple platforms, enabling seamless integration with various sensors and hardware components. In contrast, PLCs are typically limited to specific industrial control applications with fixed hardware configurations, making them less adaptable to expanding system requirements. Your choice between ROS and PLC should consider the need for flexible integration and scalability in complex automation environments.

Application Domains: Where ROS and PLC Shine

ROS excels in robotics research, autonomous vehicles, and complex robotic systems requiring advanced perception, navigation, and machine learning capabilities. PLCs dominate industrial automation, manufacturing processes, and control systems demanding high reliability, real-time performance, and rugged operation in harsh environments. While ROS is preferred for flexible, experimental robotics applications, PLCs are integral to standardized, safety-critical industrial control tasks.

Cost and Maintenance Considerations

ROS (Robot Operating System) offers lower upfront costs due to its open-source nature and extensive community support, reducing software licensing fees compared to proprietary PLC systems. Maintenance expenses for ROS can be minimized through modular software components and frequent updates, but may require skilled personnel to manage system integration and troubleshooting. PLCs, while typically more expensive initially, provide robust reliability and standardized hardware, resulting in predictable maintenance schedules and lower downtime costs in industrial environments.

Future Trends in Industrial Automation

Future trends in industrial automation highlight ROS's growing role in enabling flexible, intelligent, and collaborative robotic systems, while PLCs remain crucial for reliable, real-time control in traditional manufacturing environments. Integration of ROS with PLCs is becoming more common, combining ROS's advanced perception and AI capabilities with the robustness and deterministic performance of PLCs. You can expect hybrid solutions to drive innovation, improving efficiency and adaptability in smart factories of the future.

Choosing the Right Solution for Your Needs

Choosing between ROS and PLC depends on your project's complexity and flexibility requirements. ROS offers advanced robotics software integration, ideal for research, development, and tasks requiring customization and machine learning. PLC systems excel in industrial automation with reliable, real-time control and simpler programming suited for repetitive manufacturing processes.

ROS vs PLC Infographic

libmatt.com

libmatt.com