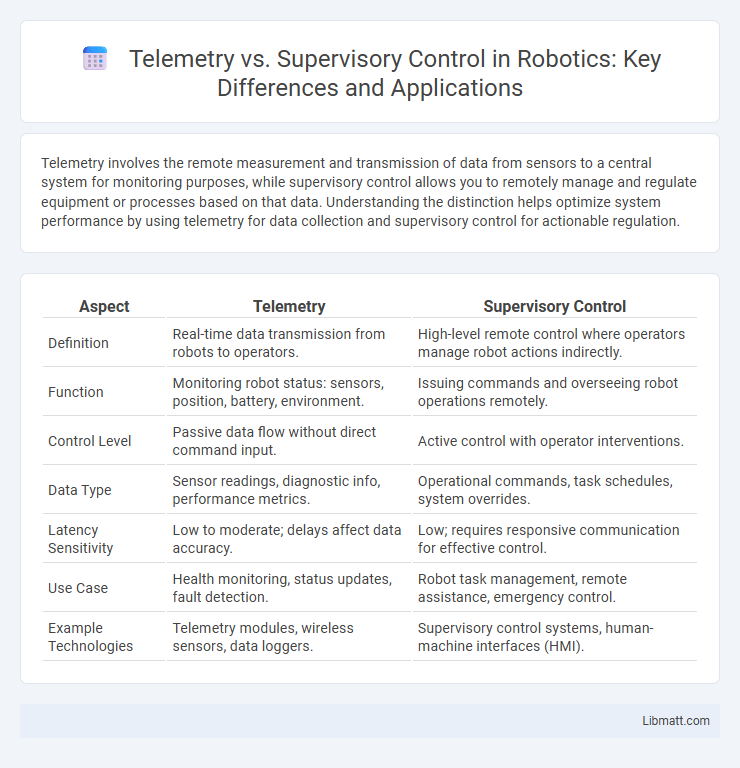

Telemetry involves the remote measurement and transmission of data from sensors to a central system for monitoring purposes, while supervisory control allows you to remotely manage and regulate equipment or processes based on that data. Understanding the distinction helps optimize system performance by using telemetry for data collection and supervisory control for actionable regulation.

Table of Comparison

| Aspect | Telemetry | Supervisory Control |

|---|---|---|

| Definition | Real-time data transmission from robots to operators. | High-level remote control where operators manage robot actions indirectly. |

| Function | Monitoring robot status: sensors, position, battery, environment. | Issuing commands and overseeing robot operations remotely. |

| Control Level | Passive data flow without direct command input. | Active control with operator interventions. |

| Data Type | Sensor readings, diagnostic info, performance metrics. | Operational commands, task schedules, system overrides. |

| Latency Sensitivity | Low to moderate; delays affect data accuracy. | Low; requires responsive communication for effective control. |

| Use Case | Health monitoring, status updates, fault detection. | Robot task management, remote assistance, emergency control. |

| Example Technologies | Telemetry modules, wireless sensors, data loggers. | Supervisory control systems, human-machine interfaces (HMI). |

Introduction to Telemetry and Supervisory Control

Telemetry involves the automatic measurement and transmission of data from remote or inaccessible points to a central system for monitoring, often used in industries like aerospace, environmental monitoring, and healthcare. Supervisory control refers to the high-level management system that oversees and regulates the operation of industrial processes or machinery, enabling real-time decision-making and adjustments. Understanding the differences between telemetry's data collection capabilities and supervisory control's command functions is essential to optimize your remote monitoring and control workflows.

Defining Telemetry: Concepts and Applications

Telemetry involves the automatic measurement and transmission of data from remote or inaccessible sources to a receiving system for monitoring and analysis. Common applications include environmental monitoring, healthcare devices, and aerospace systems where real-time data collection is critical for decision-making. Telemetry systems enable precise tracking of parameters such as temperature, pressure, and performance metrics without the need for direct human intervention.

What is Supervisory Control? Key Features and Usage

Supervisory control involves centralized monitoring and managing of multiple remote systems or processes to ensure efficient and safe operation. Key features include real-time data acquisition, command transmission, alarm handling, and remote process adjustment, enabling supervisors to oversee complex industrial or infrastructure networks effectively. Your ability to intervene promptly based on aggregated telemetry data enhances operational reliability and prevents system failures.

Core Differences Between Telemetry and Supervisory Control

Telemetry involves the automatic measurement and transmission of data from remote or inaccessible locations to a central system for monitoring, emphasizing data collection and reporting. Supervisory control extends beyond data gathering by enabling operators to send commands and control processes remotely, integrating both monitoring and direct intervention capabilities. The core distinction lies in telemetry's passive data relay function, whereas supervisory control includes active management and control of systems.

Data Acquisition in Telemetry vs Supervisory Control

Data acquisition in telemetry involves remote measurement and transmission of sensor data to a central system, enabling real-time monitoring without direct human intervention. Supervisory control incorporates data acquisition as part of a broader system, collecting data locally to enable centralized oversight and automated decision-making for process adjustments. Your choice depends on whether you need long-distance, autonomous data collection (telemetry) or integrated control with immediate supervisory feedback.

Communication Protocols: Telemetry vs Supervisory Control

Telemetry systems primarily use communication protocols like MQTT, Modbus, and DNP3 to transmit sensor data from remote devices to central monitoring stations, emphasizing efficient, real-time data collection with minimal latency. Supervisory control systems rely heavily on SCADA protocols such as IEC 60870-5-104 and OPC UA, ensuring reliable bidirectional communication for both monitoring and executing control commands within industrial processes. The choice of protocol impacts data integrity, security, and latency, with telemetry favoring lightweight protocols for streamlined data flow and supervisory control demanding robust, secure protocols for operational command execution.

Real-Time Monitoring: Contrasting Approaches

Telemetry enables real-time monitoring by transmitting sensor data from remote locations directly to central systems for immediate analysis, ensuring rapid response to changing conditions. Supervisory control integrates this data with control functions, allowing operators to not only observe but also manage and adjust processes in real time through human-machine interfaces (HMIs). The combination of telemetry data and supervisory control systems facilitates dynamic decision-making and enhanced operational efficiency in industrial automation environments.

Use Cases: Industry Applications for Each System

Telemetry systems are widely used in industries such as oil and gas, aerospace, and environmental monitoring to collect and transmit real-time data from remote or inaccessible locations for analysis and decision-making. Supervisory control finds its primary applications in manufacturing, power generation, and water treatment plants, where operators remotely monitor and control equipment to maintain process efficiency and safety. Your choice depends on whether continuous data acquisition or active control over industrial processes is the priority.

Pros and Cons: Telemetry Compared to Supervisory Control

Telemetry enables real-time data collection from remote sensors, offering continuous monitoring with minimal human intervention but may suffer from limited control capabilities and potential data transmission delays. Supervisory control provides centralized management and the ability to make immediate adjustments to system operations, enhancing responsiveness but requiring more complex infrastructure and higher operational costs. While telemetry excels in data accuracy and passive observation, supervisory control advantages lie in dynamic decision-making and system manipulation.

Choosing the Right System: Factors for Decision Making

Choosing the right system between telemetry and supervisory control depends on key factors such as real-time data needs, system complexity, and scalability requirements. Telemetry excels in remote data collection and monitoring, offering precise, continuous data streams ideal for distributed environments. Supervisory control prioritizes centralized command and automation, making it suitable for integrated process management and rapid response in controlled settings.

Telemetry vs Supervisory control Infographic

libmatt.com

libmatt.com