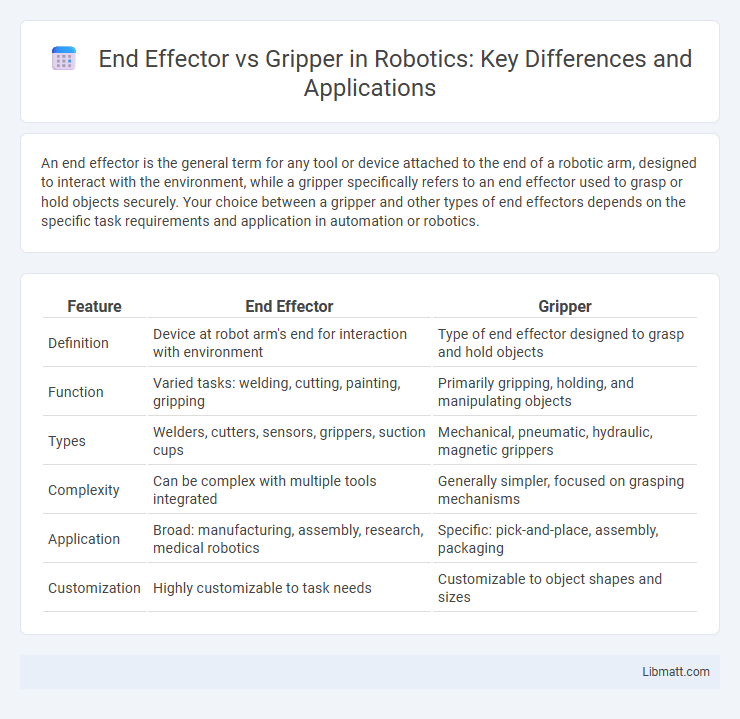

An end effector is the general term for any tool or device attached to the end of a robotic arm, designed to interact with the environment, while a gripper specifically refers to an end effector used to grasp or hold objects securely. Your choice between a gripper and other types of end effectors depends on the specific task requirements and application in automation or robotics.

Table of Comparison

| Feature | End Effector | Gripper |

|---|---|---|

| Definition | Device at robot arm's end for interaction with environment | Type of end effector designed to grasp and hold objects |

| Function | Varied tasks: welding, cutting, painting, gripping | Primarily gripping, holding, and manipulating objects |

| Types | Welders, cutters, sensors, grippers, suction cups | Mechanical, pneumatic, hydraulic, magnetic grippers |

| Complexity | Can be complex with multiple tools integrated | Generally simpler, focused on grasping mechanisms |

| Application | Broad: manufacturing, assembly, research, medical robotics | Specific: pick-and-place, assembly, packaging |

| Customization | Highly customizable to task needs | Customizable to object shapes and sizes |

Introduction to End Effectors and Grippers

End effectors are devices attached to the end of robotic arms designed to interact with objects, performing tasks such as gripping, welding, or sensing. Grippers are a specific type of end effector specialized in grasping and holding objects, often using mechanical fingers or suction mechanisms. Understanding the distinction between end effectors and grippers helps optimize Your robotic system's functionality for various applications.

Defining End Effectors: Scope and Functions

End effectors are devices attached to the end of a robotic arm designed to interact with the environment, encompassing a wide range of tools such as grippers, welding torches, and suction cups. Their primary function is to manipulate objects or perform specific tasks, enabling robots to handle diverse applications across manufacturing, assembly, and material handling. Unlike grippers, which specifically focus on grasping and holding objects, end effectors provide broader functionalities tailored to various industrial needs.

What is a Gripper? Types and Applications

A gripper is a mechanical device attached to the end effector of a robot, designed to grasp, hold, and manipulate objects with precision. Common types of grippers include mechanical, pneumatic, hydraulic, and magnetic, each suited for specific applications such as assembly lines, packaging, material handling, and delicate object manipulation. Your choice of gripper depends on factors like object shape, weight, and required gripping force, optimizing the robot's efficiency in industrial or laboratory environments.

Key Differences Between End Effectors and Grippers

End effectors serve as the functional tool mounted on the robotic arm, designed for various tasks such as welding, painting, or material handling, whereas grippers specifically focus on grasping, holding, and manipulating objects. The key difference lies in versatility: end effectors encompass a wide range of tool types, while grippers are a subset dedicated to gripping mechanisms. Understanding your application's requirements helps determine whether a general end effector or a specialized gripper is the optimal choice for enhancing robotic performance.

Common Types of End Effectors in Robotics

Common types of end effectors in robotics include grippers, which are designed to grasp and manipulate objects using mechanical fingers or jaws, and tools such as welding torches, suction cups, and sensors that perform specialized functions. Grippers are widely used for pick-and-place tasks due to their adaptability and precision in handling various shapes and sizes. Your choice of end effector depends on the specific application requirements, ensuring optimal compatibility with the robot's task environment.

Advantages of Using Grippers

Grippers offer precise control and versatility in handling various objects, making them ideal for automation tasks in manufacturing and assembly lines. Their ability to easily adapt to different shapes and sizes enhances operational efficiency and reduces downtime. Using grippers improves Your system's accuracy and reliability in material manipulation, leading to higher productivity.

Limitations of Grippers Compared to Other End Effectors

Grippers are limited in versatility and precision compared to other end effectors like vacuum cups or magnetic grippers, as they primarily rely on mechanical clamping which may not suit delicate or irregularly shaped objects. Their gripping force can cause damage to fragile items, restricting their use in industries requiring gentle handling, such as electronics or food processing. Your choice of end effector should consider these limitations to ensure compatibility with the specific application and workpiece characteristics.

Selection Criteria: Choosing End Effector vs Gripper

Selection criteria between an end effector and a gripper hinge on application requirements such as precision, payload capacity, and object complexity. End effectors offer versatility for tasks requiring multiple functions or tooling changes, while grippers specialize in securely grasping and manipulating specific objects with mechanical or vacuum-based mechanisms. Evaluating factors like environmental conditions, cycle speed, and maintenance needs ensures optimal choice for industrial automation and robotic operations.

Industry Applications: End Effector and Gripper Use Cases

End effectors and grippers serve crucial roles in diverse industry applications, with end effectors offering multifunctional tools for tasks such as welding, painting, and assembly in automotive manufacturing. Grippers are specialized for precise handling and manipulation of objects, widely used in packaging, electronics, and food processing industries for secure gripping and placement. Your choice between an end effector and a gripper depends on the complexity of the task and the specific requirements of the industrial application.

Future Trends in End Effectors and Gripper Technology

Future trends in end effectors and gripper technology emphasize advanced sensor integration and AI-driven adaptability to enhance precision and efficiency in automation. Robotics manufacturers are increasingly developing modular end effectors with interchangeable grippers tailored for diverse industrial applications, promoting greater flexibility. Innovations in soft robotics and bio-inspired designs are revolutionizing gripper functionality, enabling delicate object handling and expanding capabilities in sectors like healthcare and electronics manufacturing.

End effector vs Gripper Infographic

libmatt.com

libmatt.com