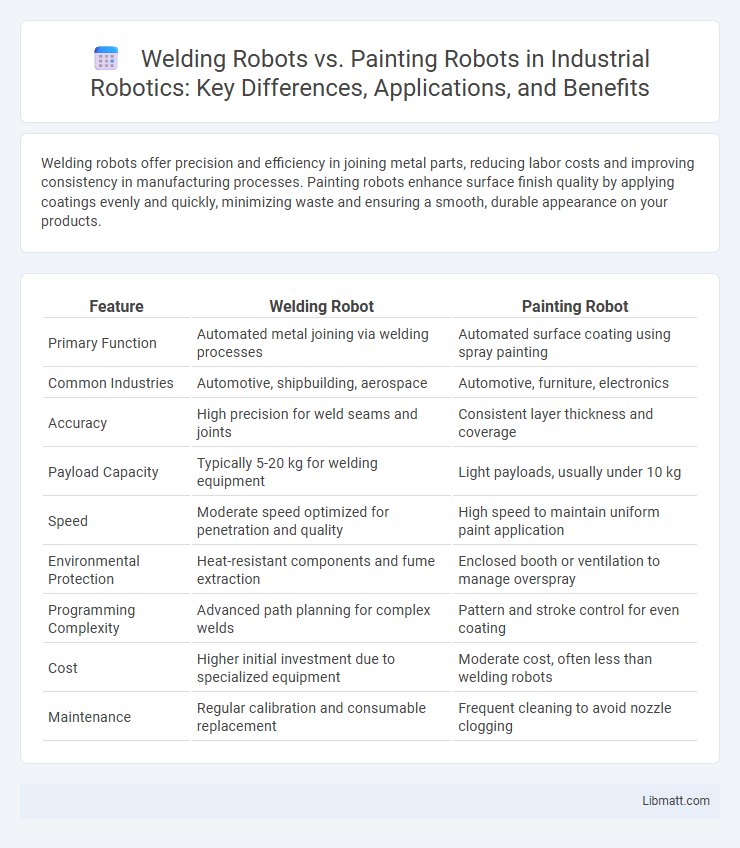

Welding robots offer precision and efficiency in joining metal parts, reducing labor costs and improving consistency in manufacturing processes. Painting robots enhance surface finish quality by applying coatings evenly and quickly, minimizing waste and ensuring a smooth, durable appearance on your products.

Table of Comparison

| Feature | Welding Robot | Painting Robot |

|---|---|---|

| Primary Function | Automated metal joining via welding processes | Automated surface coating using spray painting |

| Common Industries | Automotive, shipbuilding, aerospace | Automotive, furniture, electronics |

| Accuracy | High precision for weld seams and joints | Consistent layer thickness and coverage |

| Payload Capacity | Typically 5-20 kg for welding equipment | Light payloads, usually under 10 kg |

| Speed | Moderate speed optimized for penetration and quality | High speed to maintain uniform paint application |

| Environmental Protection | Heat-resistant components and fume extraction | Enclosed booth or ventilation to manage overspray |

| Programming Complexity | Advanced path planning for complex welds | Pattern and stroke control for even coating |

| Cost | Higher initial investment due to specialized equipment | Moderate cost, often less than welding robots |

| Maintenance | Regular calibration and consumable replacement | Frequent cleaning to avoid nozzle clogging |

Introduction to Welding and Painting Robots

Welding robots are automated machines designed to perform precise and high-speed welding tasks, commonly used in automotive and manufacturing industries to enhance production efficiency and consistency. Painting robots specialize in applying coatings evenly and consistently, reducing material waste and ensuring a high-quality finish on surfaces such as car bodies and industrial equipment. Your choice between welding and painting robots depends on the specific application requirements, including the type of material processing and desired automation level.

Key Differences Between Welding and Painting Robots

Welding robots are designed for precision metal fabrication tasks, using high-temperature processes to join materials, while painting robots focus on evenly applying coatings for surface protection and aesthetics. The key differences lie in their end-effectors, programming complexity, and required safety measures, with welding robots needing specialized sensors for heat and spatter control and painting robots requiring systems to manage spray patterns and environmental contaminants. Your choice depends on production goals, material handling needs, and desired finish quality.

Core Functions of Welding Robots

Welding robots specialize in automating metal joining processes such as arc welding, spot welding, and laser welding to ensure precision, consistency, and high production rates. These robots utilize advanced sensors and programming to control heat input, weld bead shape, and penetration depth, significantly reducing human error and improving structural integrity. Your manufacturing line benefits from increased efficiency and reduced labor costs when deploying welding robots compared to painting robots designed mainly for surface coating and finishing tasks.

Core Functions of Painting Robots

Painting robots primarily focus on applying consistent and precise coatings to surfaces, ensuring uniform coverage and finish quality in automotive and industrial manufacturing. These robots use advanced spray nozzles and programmable motion paths to optimize paint usage, reduce waste, and minimize environmental impact. Your production line benefits from increased efficiency, improved surface aesthetics, and reduced exposure to hazardous fumes.

Advantages of Using Welding Robots

Welding robots offer heightened precision, consistent quality, and increased production speed, making them ideal for complex and repetitive welding tasks. Their use significantly reduces human exposure to hazardous fumes and intense heat, improving workplace safety. By integrating welding robots into your manufacturing process, you can achieve lower operational costs and enhanced overall efficiency.

Benefits of Deploying Painting Robots

Deploying painting robots ensures consistent, high-quality finishes with reduced overspray and waste, enhancing cost efficiency in industrial applications. These robots improve workplace safety by minimizing human exposure to harmful fumes and repetitive strain injuries associated with manual painting. Your production process benefits from faster cycle times and precise control, increasing overall productivity and reducing rework costs.

Industry Applications: Welding vs Painting Robots

Welding robots dominate automotive and heavy machinery industries, excelling in precision metal joining and high-volume production lines, enhancing efficiency and consistency. Painting robots are widely used in consumer electronics and furniture manufacturing, providing uniform coating and reducing overspray waste with advanced spray techniques. Your choice between welding and painting robots should align with your specific industry demands, material types, and production goals.

Precision and Efficiency Comparison

Welding robots achieve high precision by maintaining consistent weld quality, minimizing human error through advanced sensors and programmable controls, which enhances efficiency in repetitive, complex tasks. Painting robots deliver uniform coatings with exact control over spray patterns and thickness, reducing overspray and material waste, leading to faster cycle times and improved cost-effectiveness. Both robots optimize manufacturing workflows but excel in precision and efficiency tailored to their specific applications--welding for structural integrity and painting for surface finish quality.

Cost and ROI Analysis: Welding vs Painting

Welding robots generally entail higher upfront costs due to complex hardware and safety features but offer rapid ROI through increased precision and reduced labor costs in metal fabrication industries. Painting robots, although less expensive initially, provide ROI through consistent finish quality, reduced paint waste, and faster cycle times in automotive and consumer goods manufacturing. Evaluating total cost of ownership and specific application demands is crucial for determining which robotic solution maximizes ROI in a given production environment.

Future Trends in Industrial Robotics for Welding and Painting

Future trends in industrial robotics highlight increased use of AI-driven welding robots capable of precise, adaptive welds in complex environments, significantly boosting efficiency and reducing errors. Painting robots are evolving with advanced sensor technology and machine learning algorithms to deliver uniform coatings, minimize overspray, and adapt to varying surface geometries autonomously. Integration of IoT and real-time data analytics is expected to enhance predictive maintenance and operational optimization for both welding and painting robotic systems in manufacturing.

Welding robot vs Painting robot Infographic

libmatt.com

libmatt.com