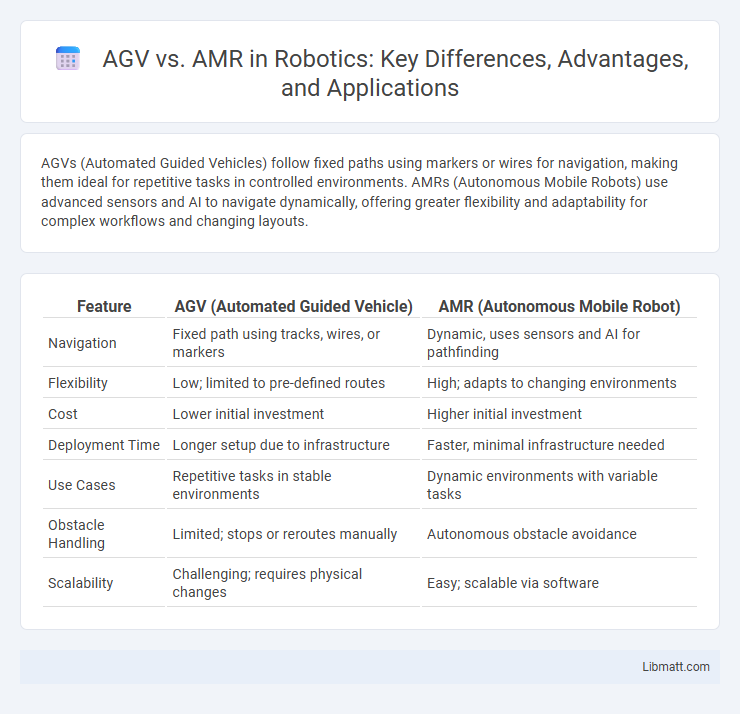

AGVs (Automated Guided Vehicles) follow fixed paths using markers or wires for navigation, making them ideal for repetitive tasks in controlled environments. AMRs (Autonomous Mobile Robots) use advanced sensors and AI to navigate dynamically, offering greater flexibility and adaptability for complex workflows and changing layouts.

Table of Comparison

| Feature | AGV (Automated Guided Vehicle) | AMR (Autonomous Mobile Robot) |

|---|---|---|

| Navigation | Fixed path using tracks, wires, or markers | Dynamic, uses sensors and AI for pathfinding |

| Flexibility | Low; limited to pre-defined routes | High; adapts to changing environments |

| Cost | Lower initial investment | Higher initial investment |

| Deployment Time | Longer setup due to infrastructure | Faster, minimal infrastructure needed |

| Use Cases | Repetitive tasks in stable environments | Dynamic environments with variable tasks |

| Obstacle Handling | Limited; stops or reroutes manually | Autonomous obstacle avoidance |

| Scalability | Challenging; requires physical changes | Easy; scalable via software |

Introduction to AGV and AMR

Automated Guided Vehicles (AGVs) are robotic systems designed to follow predetermined paths for transporting materials in warehouses or manufacturing environments. Autonomous Mobile Robots (AMRs) utilize advanced sensors and AI to navigate dynamically, adapting routes in real-time without fixed guides. Understanding the differences in navigation and flexibility between AGVs and AMRs can help you select the best solution for optimizing your material handling processes.

Defining AGVs: Key Features and Functions

Automated Guided Vehicles (AGVs) are robotic systems designed to transport materials within industrial settings using fixed pathways such as magnetic strips or wires embedded in the floor. Key features include pre-defined routes, sensors for navigation and obstacle detection, and integration with warehouse management systems to optimize workflow efficiency. Understanding AGVs' functions helps you determine the right automated solution for streamlined material handling and logistics operations.

Exploring AMRs: Core Capabilities and Technology

Autonomous Mobile Robots (AMRs) employ advanced sensors, machine learning, and sophisticated navigation algorithms to adapt dynamically to their environment, outperforming traditional Automated Guided Vehicles (AGVs). Unlike AGVs, which follow fixed paths using physical guides, AMRs utilize real-time mapping and obstacle detection to optimize routes and improve operational efficiency. Your facility can benefit from AMRs' flexibility and scalability, enhancing productivity in complex and changing logistics environments.

AGV vs AMR: Main Differences

Automated Guided Vehicles (AGVs) navigate using fixed paths such as magnetic strips or wires, making them ideal for repetitive tasks in structured environments, whereas Autonomous Mobile Robots (AMRs) employ advanced sensors, cameras, and AI-driven navigation to dynamically map and adapt to their surroundings in real-time. AGVs typically require significant infrastructure modifications and are limited to predefined routes, while AMRs operate with greater flexibility, capable of handling complex workflows and obstacle avoidance without external guidance systems. The key distinction lies in AMRs' ability to learn and optimize routes autonomously, vastly improving efficiency in dynamic industrial or warehouse settings.

Navigation Systems: Laser, Vision, and Beyond

Automated Guided Vehicles (AGVs) primarily rely on laser navigation systems such as LiDAR for precise path following within defined routes, whereas Autonomous Mobile Robots (AMRs) use advanced vision-based systems combined with LiDAR and simultaneous localization and mapping (SLAM) technology to dynamically navigate complex environments. AGVs require fixed infrastructure like magnetic tapes or reflectors to guide their movements, while AMRs leverage AI-powered sensors and cameras for real-time obstacle detection and route optimization beyond static paths. The integration of multi-sensor fusion in AMRs enables flexible, autonomous operations with higher adaptability and operational efficiency compared to traditional AGV navigation systems.

Deployment and Integration in Warehouses

Autonomous Guided Vehicles (AGVs) require fixed infrastructure such as magnetic tape or wires for navigation, leading to longer deployment times and higher installation costs in warehouses. In contrast, Autonomous Mobile Robots (AMRs) utilize advanced sensors and AI-driven mapping to dynamically navigate complex environments without physical guides, allowing for rapid deployment and seamless integration with existing warehouse management systems (WMS). The flexibility of AMRs supports scalable operations and adaptability to layout changes, while AGVs are better suited for repetitive tasks within structured environments.

Safety and Flexibility Comparison

AGVs (Automated Guided Vehicles) operate on fixed paths defined by embedded wires or magnetic strips, limiting flexibility but providing consistent safety through predictable navigation. AMRs (Autonomous Mobile Robots) utilize advanced sensors and AI to dynamically navigate complex environments, enhancing flexibility while maintaining high safety standards via real-time obstacle detection and avoidance. Safety protocols in AMRs adapt to changing conditions more effectively than AGVs, making AMRs better suited for dynamic, unstructured industrial environments.

Cost Considerations: AGV vs AMR

Automated Guided Vehicles (AGVs) typically involve higher initial investment due to fixed infrastructure requirements like wired paths or magnetic tape installations, whereas Autonomous Mobile Robots (AMRs) offer a more flexible and scalable option with lower upfront costs thanks to advanced navigation technology. Operational expenses for AGVs include maintenance of physical guides and limited adaptability, while AMRs reduce long-term costs through dynamic rerouting and software updates, improving efficiency in variable environments. When evaluating total cost of ownership, AMRs provide better ROI in complex or expanding facilities, whereas AGVs may be cost-effective in stable, repetitive workflows.

Choosing the Right Solution for Your Facility

Choosing between AGV (Automated Guided Vehicles) and AMR (Autonomous Mobile Robots) depends on your facility's specific operational needs and environment. AGVs follow fixed paths using wires or magnetic strips, ideal for repetitive tasks in structured layouts, while AMRs use advanced sensors and AI to navigate dynamically in complex or changing spaces. Evaluating your workflow complexity, flexibility requirements, and scalability will help determine the most efficient solution for your facility.

Future Trends in Autonomous Material Handling

AGV and AMR technologies are evolving to incorporate advanced AI, machine learning, and improved sensor systems, enabling greater adaptability and efficiency in autonomous material handling. Future trends highlight seamless integration with IoT and Industry 4.0 platforms, enhancing real-time data analytics and predictive maintenance. Your operations can benefit from these innovations by achieving higher automation levels and smarter workflows, reducing downtime and operational costs.

AGV vs AMR Infographic

libmatt.com

libmatt.com