EtherCAT offers superior real-time performance with low latency and jitter, making it ideal for high-speed robotic control and synchronization. PROFINET provides robust network diagnostics and integrates well with existing industrial Ethernet infrastructure, enhancing Your system's scalability and maintenance capabilities in robotics applications.

Table of Comparison

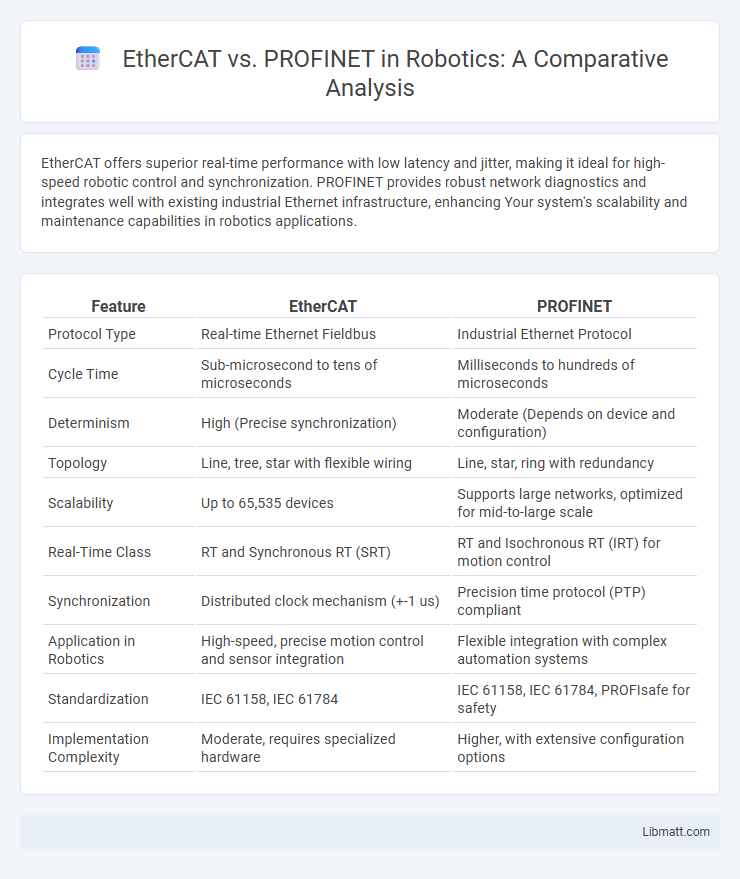

| Feature | EtherCAT | PROFINET |

|---|---|---|

| Protocol Type | Real-time Ethernet Fieldbus | Industrial Ethernet Protocol |

| Cycle Time | Sub-microsecond to tens of microseconds | Milliseconds to hundreds of microseconds |

| Determinism | High (Precise synchronization) | Moderate (Depends on device and configuration) |

| Topology | Line, tree, star with flexible wiring | Line, star, ring with redundancy |

| Scalability | Up to 65,535 devices | Supports large networks, optimized for mid-to-large scale |

| Real-Time Class | RT and Synchronous RT (SRT) | RT and Isochronous RT (IRT) for motion control |

| Synchronization | Distributed clock mechanism (+-1 us) | Precision time protocol (PTP) compliant |

| Application in Robotics | High-speed, precise motion control and sensor integration | Flexible integration with complex automation systems |

| Standardization | IEC 61158, IEC 61784 | IEC 61158, IEC 61784, PROFIsafe for safety |

| Implementation Complexity | Moderate, requires specialized hardware | Higher, with extensive configuration options |

Introduction to Industrial Communication Protocols in Robotics

EtherCAT and PROFINET are industrial communication protocols widely used in robotics for real-time data exchange and control. EtherCAT excels with its high-speed, deterministic performance and low communication latency, making it ideal for synchronized motion control and complex robotic applications. PROFINET offers robust integration with existing Ethernet networks and flexible topology options, enhancing your industrial automation system's scalability and diagnostics capabilities.

Overview of EtherCAT

EtherCAT is a real-time Ethernet protocol widely used in robotics for its deterministic communication and ultra-low latency, enabling precise synchronization of multiple servo drives and sensors. It operates by processing data on the fly within the network devices, significantly reducing cycle times and improving system responsiveness compared to traditional fieldbuses. EtherCAT's flexibility and high performance make it ideal for complex robotic applications requiring fast, reliable data exchange and scalability.

Overview of PROFINET

PROFINET is an industrial Ethernet standard widely used in robotics for real-time communication and seamless integration of automation devices. It supports high-speed data transfer, precise synchronization, and flexible network topology, making it ideal for complex robotic systems requiring robust control and diagnostics. Your robotic setup benefits from PROFINET's scalability and interoperability with existing industrial protocols, ensuring efficient and reliable operation.

Real-Time Performance Comparison

EtherCAT and PROFINET are leading industrial Ethernet protocols used in robotics, with EtherCAT delivering superior real-time performance through its on-the-fly processing and minimal communication latency, achieving cycle times as low as 100 microseconds. PROFINET, particularly PROFINET IRT, supports deterministic communication with cycle times typically around 1 millisecond, suitable for less time-critical applications. EtherCAT's low jitter and high synchronicity provide enhanced precision for high-speed robotics, whereas PROFINET offers greater integration flexibility within existing Ethernet networks.

Data Transmission Speed and Latency

EtherCAT offers significantly lower latency and higher data transmission speeds compared to PROFINET, making it ideal for real-time robotic control systems requiring rapid response times. Its master-slave communication structure enables continuous data processing during transmission, reducing cycle times to microseconds. PROFINET, while supporting high-speed communication, typically exhibits higher latency due to its Ethernet-based TCP/IP protocol stack, affecting time-critical robotic applications.

Scalability and Network Topology

EtherCAT excels in scalability and network topology flexibility, supporting large-scale robotic systems through its real-time, ring or line topologies that minimize latency and maximize synchronization. PROFINET offers versatile star, line, and ring topologies with integrated redundancy options suitable for complex automation environments but may experience higher jitter compared to EtherCAT. Your choice depends on whether you prioritize ultra-fast, deterministic communication (EtherCAT) or broader integration with existing industrial Ethernet networks (PROFINET).

Ease of Integration and Compatibility

EtherCAT offers seamless ease of integration with robotics systems due to its lightweight protocol and real-time performance, making it highly compatible with a wide range of industrial controllers and devices. PROFINET provides robust compatibility through standardized Ethernet-based communication, supporting complex network topologies and extensive device profiles for diverse robotic applications. Both protocols enable smooth integration, but EtherCAT's deterministic cycle times and simple wiring often lead to faster deployment in high-precision robotic environments.

Safety and Reliability Features

EtherCAT offers deterministic real-time communication with minimal latency, enhancing safety by ensuring swift responses in robotic control systems. PROFINET incorporates integrated safety protocols like PROFIsafe, enabling reliable transmission of fail-safe data critical for emergency stop functions and collision avoidance. Both protocols support redundancy and error detection mechanisms, but EtherCAT's distributed clock synchronization provides superior reliability for coordinating high-speed robotic movements.

Cost Considerations and Implementation

EtherCAT offers a cost-effective solution for robotics automation due to its simpler network infrastructure and reduced cabling requirements, lowering overall installation expenses compared to PROFINET. PROFINET, while typically more expensive initially because of its complex setup and advanced features, provides scalable and flexible integration options ideal for large-scale or heterogeneous robotic systems. Implementation of EtherCAT often results in faster deployment and easier maintenance, whereas PROFINET requires more specialized knowledge but supports extensive diagnostics and broader vendor compatibility.

Choosing Between EtherCAT and PROFINET for Robotics Applications

Choosing between EtherCAT and PROFINET for robotics applications depends on the specific requirements of your system, such as real-time performance, network topology, and device compatibility. EtherCAT offers superior real-time capabilities with low latency and high synchronization accuracy, making it ideal for high-speed robotic control and precise motion tasks. PROFINET provides flexible topology options and seamless integration with existing Industrial Ethernet infrastructures, which benefits applications requiring scalability and broad vendor support.

EtherCAT vs PROFINET in Robotics Infographic

libmatt.com

libmatt.com