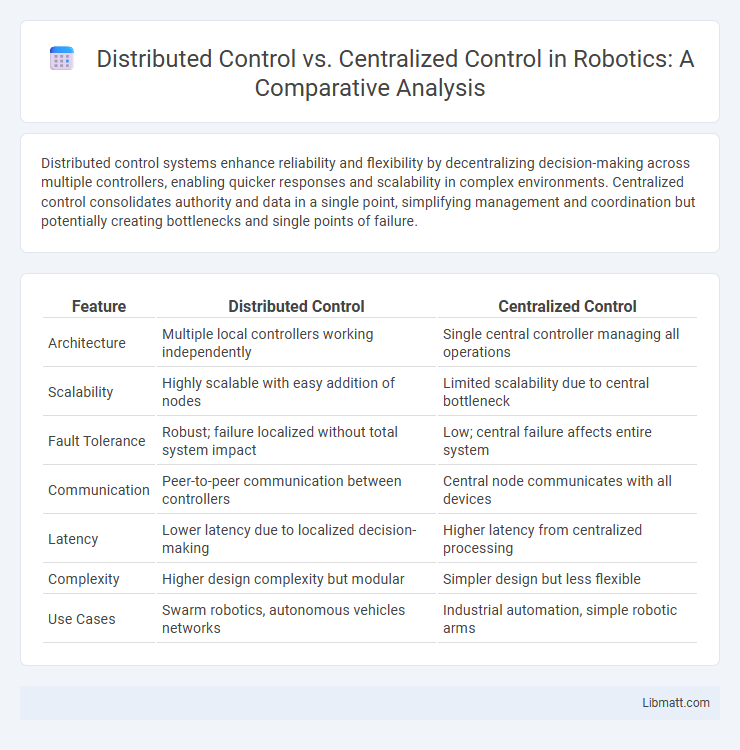

Distributed control systems enhance reliability and flexibility by decentralizing decision-making across multiple controllers, enabling quicker responses and scalability in complex environments. Centralized control consolidates authority and data in a single point, simplifying management and coordination but potentially creating bottlenecks and single points of failure.

Table of Comparison

| Feature | Distributed Control | Centralized Control |

|---|---|---|

| Architecture | Multiple local controllers working independently | Single central controller managing all operations |

| Scalability | Highly scalable with easy addition of nodes | Limited scalability due to central bottleneck |

| Fault Tolerance | Robust; failure localized without total system impact | Low; central failure affects entire system |

| Communication | Peer-to-peer communication between controllers | Central node communicates with all devices |

| Latency | Lower latency due to localized decision-making | Higher latency from centralized processing |

| Complexity | Higher design complexity but modular | Simpler design but less flexible |

| Use Cases | Swarm robotics, autonomous vehicles networks | Industrial automation, simple robotic arms |

Introduction to Control Systems

Distributed control systems (DCS) decentralize the control process by using multiple controllers located throughout the system, enhancing scalability and fault tolerance in complex industrial applications. Centralized control systems consolidate decision-making into a single controller, simplifying management but creating potential single points of failure and limitations in handling large-scale operations. Both control architectures are fundamental in automation, with distributed control offering improved flexibility and resilience compared to traditional centralized control frameworks.

Defining Distributed Control

Distributed control involves decentralizing decision-making across multiple controllers or nodes within a system, allowing local units to operate independently while communicating for coordinated performance. This approach enhances system reliability, scalability, and fault tolerance compared to centralized control, where a single controller manages the entire process. You benefit from distributed control through improved responsiveness and flexibility in complex, large-scale industrial or networked environments.

Understanding Centralized Control

Centralized control consolidates decision-making authority within a single control unit or operator, optimizing system coordination and simplifying management. It enables streamlined data processing and consistent policy enforcement, improving performance in environments where quick, uniform responses are essential. Your ability to monitor and adjust processes in real time is enhanced, though this can create vulnerabilities if the central controller fails.

Key Differences Between Distributed and Centralized Control

Distributed control systems (DCS) decentralize decision-making by spreading control functions across multiple controllers, enhancing scalability and system reliability. Centralized control consolidates authority in a single control unit, simplifying management but increasing vulnerability to single points of failure. Your choice depends on factors like system complexity, desired fault tolerance, and operational flexibility.

Scalability and Flexibility Considerations

Distributed control systems provide superior scalability by allowing incremental expansion and adaptation without overhauling the entire infrastructure, supporting flexibility in dynamic environments. Centralized control systems face limitations in scalability as system growth demands increased processing power and communication bandwidth concentrated at a single point, reducing flexibility. The decentralized architecture of distributed control enhances fault tolerance and facilitates localized decision-making, optimizing performance for large-scale and evolving operations.

Reliability and Fault Tolerance

Distributed control systems enhance reliability by decentralizing decision-making, reducing single points of failure and enabling continuous operation despite individual node malfunctions. Centralized control systems often face higher risks of complete shutdown during faults due to dependence on a single control unit, impacting overall system availability. Fault tolerance in distributed control is improved through redundancy and real-time data sharing among multiple controllers, facilitating rapid fault detection and isolation.

Security Implications in Control Architectures

Distributed control architectures enhance security by minimizing single points of failure and allowing localized threat detection, reducing the risk of widespread system compromise. Centralized control systems, while easier to manage, present a higher risk of cyberattacks due to their reliance on a single control unit that, if breached, can disrupt the entire operation. Protecting your control infrastructure involves assessing these security implications carefully to choose an architecture that balances operational efficiency with robust defense against cyber threats.

Real-world Applications and Industry Examples

Distributed control systems (DCS) are widely used in complex industrial processes such as chemical plants, oil refineries, and power generation facilities, where real-time monitoring and localized control enhance operational efficiency and fault tolerance. Centralized control systems are common in traditional manufacturing environments and utility grids where a single control center manages entire operations, offering streamlined oversight but less flexibility. Your choice between distributed and centralized control depends on the scale, complexity, and specific monitoring needs of your industry application.

Pros and Cons of Distributed vs Centralized Control

Distributed control systems offer enhanced reliability and scalability by decentralizing decision-making, reducing single points of failure, and enabling faster local responses in industrial processes. However, they can introduce complexity in coordination and higher initial setup costs compared to centralized control, which simplifies management and integration through a single control unit but suffers from potential bottlenecks and vulnerability to complete system failure. Centralized control excels in environments requiring uniform control and easy oversight, while distributed control is better suited for large-scale or geographically dispersed operations demanding robustness and flexibility.

Choosing the Right Control System for Your Needs

Distributed control systems (DCS) offer enhanced scalability, fault tolerance, and localized decision-making, ideal for complex industrial processes requiring real-time responsiveness and flexibility. Centralized control systems (CCS) provide streamlined management and simplified oversight, best suited for smaller operations where centralized data collection and decision authority are paramount. Selecting between DCS and CCS depends on factors such as system complexity, required reliability, operational scale, and the need for decentralized autonomy versus centralized control efficiency.

Distributed control vs Centralized control Infographic

libmatt.com

libmatt.com