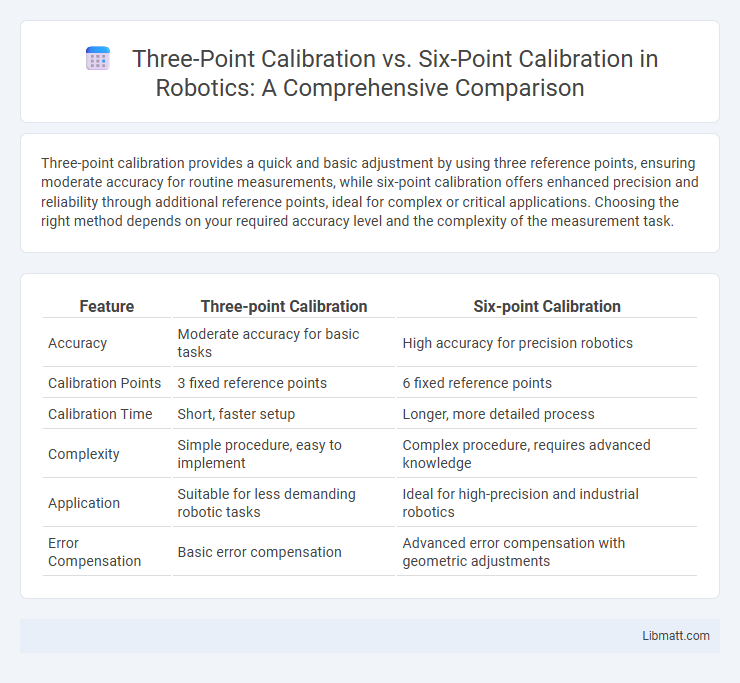

Three-point calibration provides a quick and basic adjustment by using three reference points, ensuring moderate accuracy for routine measurements, while six-point calibration offers enhanced precision and reliability through additional reference points, ideal for complex or critical applications. Choosing the right method depends on your required accuracy level and the complexity of the measurement task.

Table of Comparison

| Feature | Three-point Calibration | Six-point Calibration |

|---|---|---|

| Accuracy | Moderate accuracy for basic tasks | High accuracy for precision robotics |

| Calibration Points | 3 fixed reference points | 6 fixed reference points |

| Calibration Time | Short, faster setup | Longer, more detailed process |

| Complexity | Simple procedure, easy to implement | Complex procedure, requires advanced knowledge |

| Application | Suitable for less demanding robotic tasks | Ideal for high-precision and industrial robotics |

| Error Compensation | Basic error compensation | Advanced error compensation with geometric adjustments |

Introduction to Calibration Methods

Three-point calibration uses three known reference points to establish sensor accuracy, ideal for applications requiring moderate precision. Six-point calibration involves six reference points, offering enhanced accuracy by correcting sensor nonlinearities across a broader measurement range. Understanding the differences between these calibration methods helps you select the appropriate approach for your specific accuracy requirements and measurement conditions.

Importance of Calibration in Measurement Systems

Calibration ensures the accuracy and reliability of measurement systems by aligning instrument outputs with known standards, directly impacting data quality and operational efficiency. Three-point calibration offers a basic accuracy check at low, mid, and high values, while six-point calibration enhances precision by covering more intermediate points, reducing measurement errors across the instrument's entire range. Your measurement results depend on rigorous calibration protocols to maintain consistency and traceability in critical applications.

Overview of Three-point Calibration

Three-point calibration involves measuring a device at three distinct points to establish accuracy across a specific range, offering a balance between simplicity and precision. This method is commonly used for sensors and instruments requiring moderate accuracy, such as temperature or pressure gauges, where the three data points help to identify linearity and correct minor deviations. You can rely on three-point calibration for efficient device verification without the complexity or time commitment of more extensive multi-point calibrations like six-point methods.

Overview of Six-point Calibration

Six-point calibration offers enhanced accuracy by using six reference points evenly distributed across the measurement range, reducing errors caused by non-linearity. Compared to three-point calibration, it provides better correction for complex sensor behaviors or instruments with wider operating ranges. Your data quality significantly improves with six-point calibration in applications requiring precise measurements and stringent compliance.

Key Differences Between Three-point and Six-point Calibration

Three-point calibration uses three reference points to establish a linear relationship between measurement values and actual values, suitable for systems with minimal non-linearity. Six-point calibration involves six reference points, offering enhanced accuracy by capturing system behavior across a broader measurement range and correcting more complex non-linear errors. The key differences lie in the number of calibration points, precision level, and the ability to adjust for non-linear deviations in measurement instruments.

Advantages of Three-point Calibration

Three-point calibration offers a balanced approach by providing accurate and reliable measurement with fewer reference points, reducing the time and complexity involved compared to six-point calibration. It ensures sufficient precision for many practical applications by covering the low, mid, and high range of the measurement scale, improving overall efficiency and ease of use. This method is cost-effective, requiring less calibration material and simpler procedures while maintaining acceptable accuracy for most standard environments.

Advantages of Six-point Calibration

Six-point calibration offers enhanced accuracy and precision over three-point calibration by covering a broader range of sensor outputs and linearizing response curves more effectively. This method reduces measurement errors across the device's full scale, improving reliability in critical applications such as laboratory analysis or industrial quality control. Your measurements benefit from increased confidence and consistency, addressing potential nonlinearities that simpler calibration methods may overlook.

Limitations of Both Calibration Methods

Three-point calibration provides a quick and straightforward method but lacks accuracy across a broader measurement range, often leading to significant errors in nonlinear systems. Six-point calibration offers improved precision by covering more points across the scale, yet it requires more time and resources and may still be insufficient for highly complex or nonlinear sensor behaviors. Both methods are limited by their reliance on the stability of reference standards and environmental conditions, which can introduce uncertainty and drift over time.

Choosing the Right Calibration Technique

Choosing the right calibration technique depends on the required accuracy and complexity of the measurement system. Three-point calibration offers a simple and faster process suitable for general applications, while six-point calibration provides enhanced precision by covering a broader range of values, ideal for critical and high-accuracy measurements. Selecting between these techniques involves balancing time, cost, and the specific performance needs of instruments such as sensors and analytical devices.

Conclusion and Best Practices

Three-point calibration provides a quick and reliable method for measuring instruments with moderate accuracy requirements, while six-point calibration offers enhanced precision by covering a broader range of values for more complex applications. Your choice should depend on the required measurement accuracy and the specific calibration standards applicable to your industry. Implementing six-point calibration is best practice for critical processes demanding tighter tolerance, whereas three-point calibration suits routine checks and less stringent quality controls.

Three-point Calibration vs Six-point Calibration Infographic

libmatt.com

libmatt.com