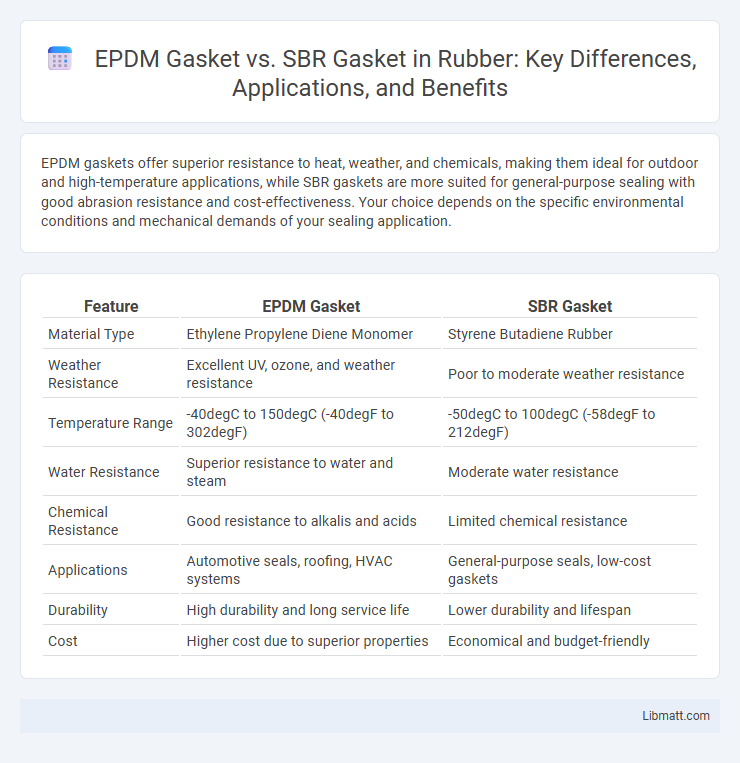

EPDM gaskets offer superior resistance to heat, weather, and chemicals, making them ideal for outdoor and high-temperature applications, while SBR gaskets are more suited for general-purpose sealing with good abrasion resistance and cost-effectiveness. Your choice depends on the specific environmental conditions and mechanical demands of your sealing application.

Table of Comparison

| Feature | EPDM Gasket | SBR Gasket |

|---|---|---|

| Material Type | Ethylene Propylene Diene Monomer | Styrene Butadiene Rubber |

| Weather Resistance | Excellent UV, ozone, and weather resistance | Poor to moderate weather resistance |

| Temperature Range | -40degC to 150degC (-40degF to 302degF) | -50degC to 100degC (-58degF to 212degF) |

| Water Resistance | Superior resistance to water and steam | Moderate water resistance |

| Chemical Resistance | Good resistance to alkalis and acids | Limited chemical resistance |

| Applications | Automotive seals, roofing, HVAC systems | General-purpose seals, low-cost gaskets |

| Durability | High durability and long service life | Lower durability and lifespan |

| Cost | Higher cost due to superior properties | Economical and budget-friendly |

Introduction to EPDM and SBR Gaskets

EPDM gaskets are made from ethylene propylene diene monomer rubber, known for excellent resistance to weathering, ozone, and a wide range of chemicals, making them ideal for outdoor and automotive applications. SBR gaskets, derived from styrene-butadiene rubber, offer good abrasion resistance and tensile strength, commonly used in industrial sealing where moderate temperature and oil resistance are required. Choosing between EPDM and SBR gaskets depends on environmental exposure, chemical compatibility, and mechanical demands of the application.

Material Composition of EPDM vs SBR Gaskets

EPDM gaskets are made from ethylene propylene diene monomer rubber, which offers excellent resistance to heat, ozone, and weathering, making them ideal for outdoor and automotive applications. SBR gaskets consist of styrene-butadiene rubber, known for its good abrasion resistance and cost-effectiveness but lower resistance to UV and ozone compared to EPDM. You should choose EPDM for durability in harsh environments, while SBR suits applications requiring mechanical strength and less exposure to the elements.

Key Physical Properties Comparison

EPDM gaskets exhibit superior resistance to heat, ozone, and weathering with an operating temperature range from -40degC to 150degC, while SBR gaskets are better suited for abrasion resistance but have a narrower temperature range of -50degC to 100degC. EPDM offers excellent chemical resistance to polar substances like acids and alkalis, whereas SBR performs well against non-polar solvents but is less resistant to oils and fuels. The elasticity of EPDM is higher, providing better sealing performance under dynamic conditions compared to the more rigid and durable structure of SBR primarily used in low-temperature applications.

Chemical Resistance: EPDM vs SBR

EPDM gaskets offer superior chemical resistance to acids, alkalis, and oxygenated solvents, making them ideal for applications involving water, steam, and certain chemicals. SBR gaskets provide limited chemical resistance and perform best with hydrocarbons and oils, but they degrade faster when exposed to ozone, weathering, and many chemicals. Your choice between EPDM and SBR gaskets should consider the specific chemical environment to ensure durability and optimal sealing performance.

Temperature Resistance Capabilities

EPDM gaskets exhibit superior temperature resistance, effectively withstanding ranges from -40degC to 150degC, making them ideal for applications involving extreme heat and cold. In contrast, SBR gaskets typically handle temperatures between -30degC and 100degC, limiting their use in high-temperature environments. Understanding your specific temperature requirements ensures the selection of the most durable gasket material for reliable sealing performance.

Common Industrial Applications

EPDM gaskets are widely used in chemical processing, water treatment, and automotive industries due to their excellent resistance to heat, ozone, and weathering. SBR gaskets are preferred in applications requiring abrasion resistance and are commonly found in oil and gas pipelines, conveyor systems, and industrial machinery. Both materials serve critical sealing functions but are selected based on their specific chemical compatibility and mechanical properties.

Durability and Lifespan Analysis

EPDM gaskets exhibit superior durability and a longer lifespan compared to SBR gaskets due to their excellent resistance to weathering, ozone, and UV exposure, making them ideal for outdoor and high-temperature applications. SBR gaskets, while cost-effective, generally have lower resistance to oil, heat, and aging, resulting in a shorter service life primarily suited for indoor environments with moderate conditions. Understanding these differences helps you choose the best gasket material to maximize longevity and reliability in your specific usage scenario.

Cost Efficiency and Availability

EPDM gaskets offer higher cost efficiency due to their longer lifespan and superior resistance to weathering, ozone, and aging, reducing replacement frequency in industrial and automotive applications. SBR gaskets, while generally less expensive upfront, have limited durability and availability, particularly in specialized forms, leading to higher long-term costs and supply constraints. Availability of EPDM is more widespread globally, supporting diverse industry needs, whereas SBR availability is often restricted by regional manufacturing capabilities.

Environmental and Safety Considerations

EPDM gaskets offer superior resistance to ozone, UV radiation, and extreme weather conditions, making them ideal for outdoor and automotive applications where environmental durability is critical. SBR gaskets, while cost-effective and suitable for general sealing purposes, exhibit lower resistance to ozone and UV exposure, limiting their use in harsh environmental conditions. EPDM's non-toxic, non-hazardous composition supports safer use in potable water and food-processing environments, whereas SBR may release harmful compounds under prolonged heat or chemical exposure.

Choosing the Right Gasket for Your Application

EPDM gaskets offer excellent resistance to heat, ozone, and weathering, making them ideal for outdoor or high-temperature applications, while SBR gaskets excel in abrasion resistance and are better suited for general-purpose sealing where oil and chemical exposure is minimal. Your choice between EPDM and SBR gaskets should be based on the specific environmental conditions and chemical exposures involved in your application to ensure optimal performance and longevity. Selecting the right gasket material enhances sealing effectiveness and prevents premature failure in critical mechanical systems.

EPDM Gasket vs SBR Gasket Infographic

libmatt.com

libmatt.com