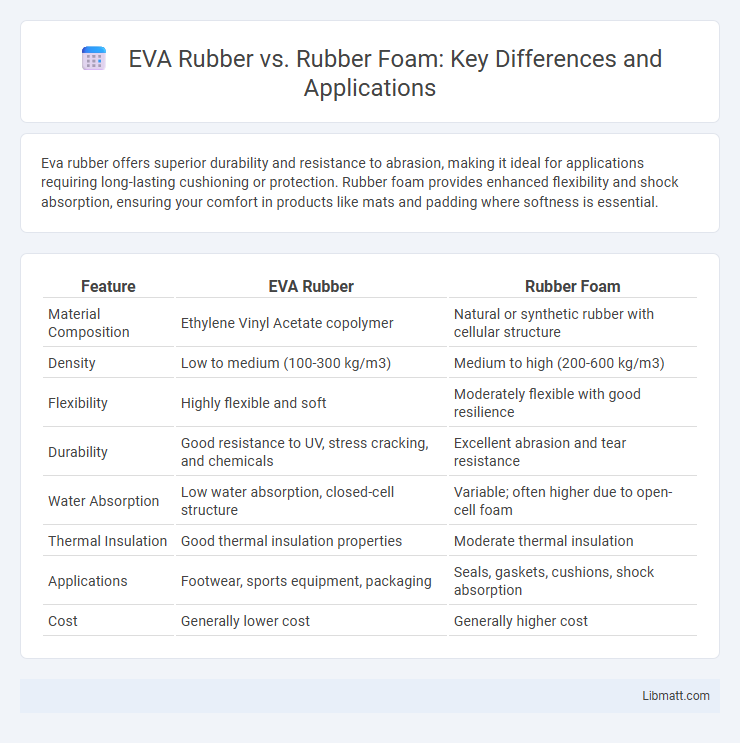

Eva rubber offers superior durability and resistance to abrasion, making it ideal for applications requiring long-lasting cushioning or protection. Rubber foam provides enhanced flexibility and shock absorption, ensuring your comfort in products like mats and padding where softness is essential.

Table of Comparison

| Feature | EVA Rubber | Rubber Foam |

|---|---|---|

| Material Composition | Ethylene Vinyl Acetate copolymer | Natural or synthetic rubber with cellular structure |

| Density | Low to medium (100-300 kg/m3) | Medium to high (200-600 kg/m3) |

| Flexibility | Highly flexible and soft | Moderately flexible with good resilience |

| Durability | Good resistance to UV, stress cracking, and chemicals | Excellent abrasion and tear resistance |

| Water Absorption | Low water absorption, closed-cell structure | Variable; often higher due to open-cell foam |

| Thermal Insulation | Good thermal insulation properties | Moderate thermal insulation |

| Applications | Footwear, sports equipment, packaging | Seals, gaskets, cushions, shock absorption |

| Cost | Generally lower cost | Generally higher cost |

Introduction to EVA Rubber and Rubber Foam

EVA rubber, or Ethylene Vinyl Acetate, is a durable, flexible material known for its excellent shock absorption and resistance to stress-cracking, commonly used in footwear, sports equipment, and cushioning. Rubber foam, typically made from natural or synthetic rubber, offers lightweight, spongy properties with superior insulation and noise reduction capabilities, making it ideal for padding and sealing applications. Understanding the distinct advantages of EVA rubber and rubber foam helps you choose the right material for comfort, durability, and performance in various products.

Composition and Material Differences

EVA rubber is a copolymer of ethylene and vinyl acetate, offering a balance of softness, flexibility, and durability with excellent resistance to UV radiation and cracking. Rubber foam, typically made from natural or synthetic rubber such as neoprene or polyurethane, features a cellular structure that provides enhanced cushioning and insulation properties. The primary difference lies in EVA's closed-cell structure, creating a lightweight and water-resistant material, whereas rubber foam's open-cell or semi-closed cell design emphasizes shock absorption and breathability.

Manufacturing Processes Compared

EVA rubber is produced through a polymerization process combining ethylene and vinyl acetate, resulting in a flexible, durable sheet material often used in shoe soles and sports equipment. Rubber foam, typically made from natural or synthetic rubber, undergoes vulcanization with gas injection or chemical blowing agents to create a lightweight, porous structure ideal for cushioning and insulation. The manufacturing difference lies in EVA's thermoplastic nature allowing easier molding and recycling, while rubber foam requires precise vulcanization control to achieve consistent cell structure and resilience.

Physical Properties: Density, Flexibility, and Durability

EVA rubber typically exhibits lower density compared to traditional rubber foam, enhancing its lightweight characteristics while maintaining excellent flexibility for diverse applications. Its closed-cell structure contributes to superior durability, offering resistance to compression and wear over time. Rubber foam, conversely, tends to have higher density with more open-cell configurations, providing greater cushioning but potentially lower long-term resilience under continuous stress.

Cushioning and Shock Absorption Capabilities

EVA rubber provides superior cushioning and shock absorption due to its closed-cell structure, which effectively disperses impact forces and reduces stress on joints. Rubber foam, while offering decent cushioning, typically has an open-cell design that allows for greater breathability but less efficient shock absorption compared to EVA. EVA's enhanced density and resilience make it a preferred choice in applications where maximum comfort and impact protection are critical.

Water and Chemical Resistance

EVA rubber offers superior water resistance and better chemical stability compared to rubber foam, making it ideal for applications exposed to moisture and harsh substances. Rubber foam tends to absorb water more easily and degrades faster when in contact with oils, solvents, or chemicals. You should choose EVA rubber for durable, long-lasting performance in wet or chemically challenging environments.

Common Uses and Industry Applications

EVA rubber is widely used in footwear, sports equipment, and automotive parts due to its excellent shock absorption and flexibility, making it ideal for insoles and cushioning. Rubber foam is commonly applied in insulation, packaging, and sealing solutions within construction and electronics industries, valued for its lightweight and thermal resistance properties. Both materials serve critical roles in manufacturing, with EVA preferred for comfort-focused products and rubber foam favored for protective and insulating functions.

Environmental Impact and Sustainability

EVA rubber offers better environmental sustainability due to its recyclability and lower emissions during production compared to traditional rubber foam, which often contains chemical additives with higher ecological footprints. Rubber foam typically relies on petroleum-based materials and may release volatile organic compounds (VOCs), contributing to air pollution and landfill waste. Choosing EVA rubber supports eco-friendly manufacturing by minimizing toxic residues and enabling more efficient recycling processes in footwear and packaging industries.

Cost Effectiveness and Market Availability

Eva rubber offers superior cost effectiveness compared to rubber foam due to its durability and lower production costs, making it an economical choice for long-term applications. Rubber foam, while often less expensive initially, tends to have shorter lifespans and may require frequent replacement, increasing overall expenses. You can find Eva rubber widely available in industrial and commercial markets, whereas rubber foam is more common in consumer products and niche applications.

Choosing Between EVA Rubber and Rubber Foam

Choosing between EVA rubber and rubber foam depends on the specific application requirements such as durability, flexibility, and cushioning. EVA rubber offers excellent resilience, flexibility, and resistance to abrasion and weather, making it ideal for sports equipment, footwear soles, and industrial uses. Rubber foam provides superior cushioning and shock absorption due to its porous structure, often preferred in insulation, padding, and vibration dampening applications.

Eva rubber vs Rubber foam Infographic

libmatt.com

libmatt.com