Antistatic rubber prevents the buildup of static electricity by providing a low level of conductivity, while static dissipative rubber controls the discharge of static electricity at a slower, controlled rate to protect sensitive electronic components. Choosing between them depends on whether you need to minimize static charge accumulation or safely dissipate static energy in your application.

Table of Comparison

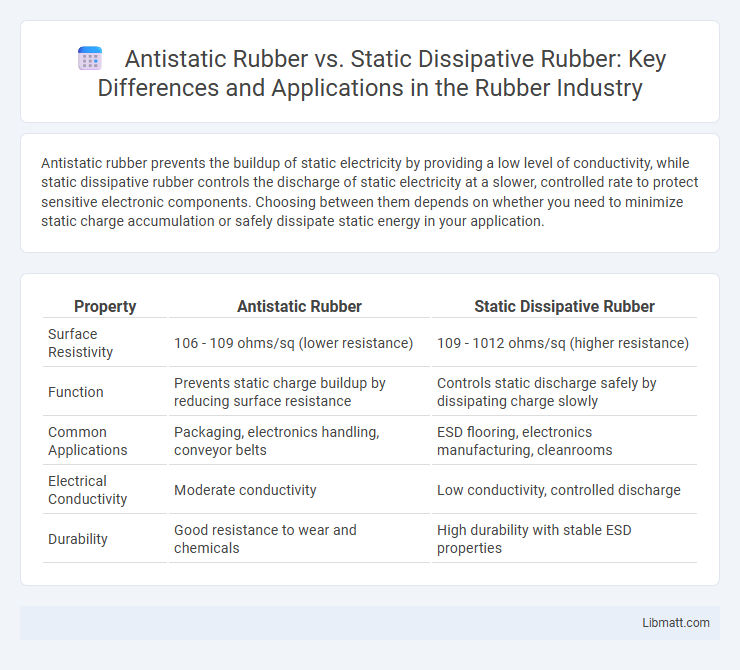

| Property | Antistatic Rubber | Static Dissipative Rubber |

|---|---|---|

| Surface Resistivity | 106 - 109 ohms/sq (lower resistance) | 109 - 1012 ohms/sq (higher resistance) |

| Function | Prevents static charge buildup by reducing surface resistance | Controls static discharge safely by dissipating charge slowly |

| Common Applications | Packaging, electronics handling, conveyor belts | ESD flooring, electronics manufacturing, cleanrooms |

| Electrical Conductivity | Moderate conductivity | Low conductivity, controlled discharge |

| Durability | Good resistance to wear and chemicals | High durability with stable ESD properties |

Introduction to Antistatic and Static Dissipative Rubber

Antistatic rubber is designed to prevent the buildup of static electricity by providing a low level of conductivity, which helps in discharging static charges slowly and safely. Static dissipative rubber offers a higher level of conductivity compared to antistatic rubber, allowing static charges to dissipate more quickly to ground, reducing the risk of sparks in sensitive environments. Both materials are essential in electronics manufacturing and environments where controlling static electricity is critical to protect components and ensure safety.

Understanding Electrostatic Discharge (ESD) Risks

Antistatic rubber reduces electrostatic discharge (ESD) by preventing static charge buildup on surfaces, creating a safer environment for sensitive electronic components. Static dissipative rubber allows charges to flow slowly to the ground, minimizing the risk of sparks that can damage your equipment or ignite flammable materials. Understanding these material properties is crucial in selecting the right protective solution for environments prone to static electricity hazards.

What is Antistatic Rubber?

Antistatic rubber is a specialized material designed to prevent the buildup of static electricity by allowing a controlled flow of electrical charge across its surface. This type of rubber typically contains conductive fillers that provide low electrical resistance, ensuring that static charges dissipate quickly without causing sparks or damage to sensitive electronic components. Understanding antistatic rubber helps you choose the right material for applications where static control is crucial, such as in electronics manufacturing or cleanroom environments.

What is Static Dissipative Rubber?

Static dissipative rubber is a type of material engineered to safely slow down and eliminate static electricity by allowing electrical charges to flow through its surface at a controlled rate. Unlike antistatic rubber, which minimizes static buildup temporarily, static dissipative rubber maintains consistent electrical conductivity within a specific resistance range of 10^5 to 10^10 ohms. Your choice of static dissipative rubber ensures enhanced protection for sensitive electronic components and reduces the risk of electrostatic discharge damage in various industrial applications.

Key Differences Between Antistatic and Static Dissipative Rubber

Antistatic rubber prevents the buildup of static electricity by allowing a slow, low-level leakage of charge, while static dissipative rubber controls the discharge of static electricity at a moderate rate to avoid sudden sparks. The key difference lies in their surface resistivity: antistatic rubber typically has a surface resistivity ranging from 10^9 to 10^12 ohms, whereas static dissipative rubber has a resistivity between 10^5 and 10^9 ohms, offering better controlled discharge. Your selection depends on the specific static protection requirements, with static dissipative rubber preferred in sensitive electronics environments due to its more consistent charge dissipation.

Material Composition and Properties

Antistatic rubber typically contains conductive fillers such as carbon black or metal oxides to reduce surface resistivity, enabling it to prevent static charge buildup by allowing controlled electrical discharge. Static dissipative rubber features a balanced polymer matrix integrated with additives like graphite or polymeric antistatic agents, offering higher surface resistivity than antistatic rubber but still allowing static charge to dissipate gradually. The key distinction lies in material composition; antistatic rubber emphasizes conductivity for rapid discharge, while static dissipative rubber prioritizes uniform resistivity to safely disperse static electricity without sudden discharge.

Typical Applications of Antistatic Rubber

Antistatic rubber is primarily used in applications where the prevention of static charge buildup is critical, such as in flooring for electronic manufacturing facilities, cleanrooms, and hospitals. It is also employed in the production of conveyor belts, footwear, and automotive parts to reduce the risk of static discharge that could damage sensitive components or create safety hazards. Typical environments include industrial settings requiring controlled electrostatic dissipation to protect both equipment and personnel.

Typical Applications of Static Dissipative Rubber

Static dissipative rubber is commonly used in applications requiring controlled surface resistivity to prevent electrostatic discharge in sensitive environments such as electronics manufacturing, cleanroom flooring, and semiconductor facilities. Its balanced conductivity allows for safe dissipation of static charges without compromising insulation properties, making it ideal for workstations, conveyor belts, and protective flooring in explosive atmospheres. Your choice of static dissipative rubber can help ensure equipment protection and personnel safety in industries where static buildup poses significant risks.

Choosing the Right Rubber for ESD Safety

Selecting the appropriate rubber for ESD safety depends on the specific electrical resistance requirements; antistatic rubber typically has a surface resistivity ranging from 10^6 to 10^9 ohms, suitable for controlling static buildup, while static dissipative rubber ranges from 10^5 to 10^9 ohms, allowing controlled charge dissipation. Static dissipative rubber is preferred in environments requiring faster discharge of static electricity to prevent sensitive electronic damage, whereas antistatic rubber is ideal for reducing initial static charge accumulation. Assessing workplace ESD standards and the sensitivity of electronic components ensures the right rubber choice to optimize safety and prevent electrostatic discharge hazards.

Summary: Which Rubber Type Suits Your Needs?

Antistatic rubber prevents the buildup of static electricity by providing a low surface resistance, making it ideal for environments sensitive to electrostatic discharge (ESD). Static dissipative rubber, however, offers controlled conductivity that safely dissipates static charges over time, better suited for precision electronic applications requiring gradual discharge. Your choice depends on whether you need immediate static prevention or controlled dissipation to protect sensitive components.

Antistatic Rubber vs Static Dissipative Rubber Infographic

libmatt.com

libmatt.com