Sheet rubber offers uniform thickness and precise dimensions, making it ideal for applications requiring consistent sealing, insulation, or gaskets. Rolled rubber provides flexibility and ease of transport, allowing you to customize the length according to your specific project needs.

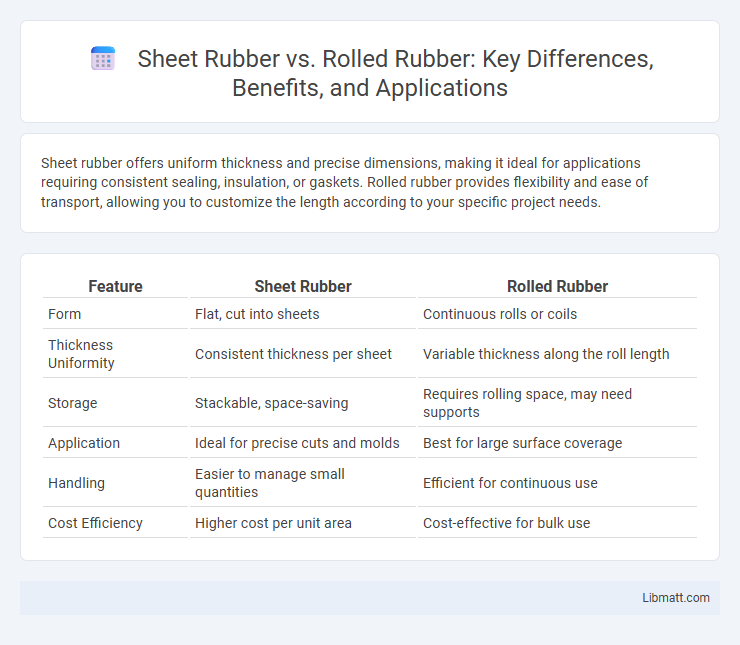

Table of Comparison

| Feature | Sheet Rubber | Rolled Rubber |

|---|---|---|

| Form | Flat, cut into sheets | Continuous rolls or coils |

| Thickness Uniformity | Consistent thickness per sheet | Variable thickness along the roll length |

| Storage | Stackable, space-saving | Requires rolling space, may need supports |

| Application | Ideal for precise cuts and molds | Best for large surface coverage |

| Handling | Easier to manage small quantities | Efficient for continuous use |

| Cost Efficiency | Higher cost per unit area | Cost-effective for bulk use |

Introduction to Sheet Rubber and Rolled Rubber

Sheet rubber consists of large, flat pieces of rubber that are evenly sliced from raw rubber blocks, offering consistent thickness and flexibility ideal for industrial applications. Rolled rubber is made by passing rubber through rollers to achieve uniform thickness in thinner, longer lengths, making it suitable for sealing, gaskets, and insulation. Understanding the distinction between sheet rubber and rolled rubber helps you select the best form for your specific manufacturing or repair needs.

Key Differences Between Sheet and Rolled Rubber

Sheet rubber consists of flat, uniform slabs typically used for precise cutting and custom applications, while rolled rubber is supplied in long, continuous rolls ideal for large surface coverage and seamless installations. Sheet rubber offers consistent thickness and ease of handling for detailed work, whereas rolled rubber provides efficiency in covering extensive areas with fewer joints. Choosing between sheet and rolled rubber depends on your project's size, application requirements, and the need for flexibility in installation.

Material Composition and Manufacturing Processes

Sheet rubber typically consists of natural or synthetic rubber compounds processed into flat, uniform sheets through calendaring or extrusion, ensuring consistent thickness and surface quality. Rolled rubber undergoes a similar composition but is manufactured by continuously pressing and rolling the material, creating long, flexible rolls that are easier to transport and cut to size. Both forms use base polymers such as SBR, NBR, or EPDM, with the primary distinction lying in their shaping methods, affecting end-use applications and handling.

Thickness and Size Variations

Sheet rubber typically offers uniform thickness and is available in large, continuous sheets ideal for custom cutting to specific sizes. Rolled rubber provides more flexibility in thickness options, often ranging from thin to very thick, suitable for applications requiring variable dimensions and easy transportation. Your choice depends on the precision of thickness needed and the size requirements for your project.

Common Applications for Sheet Rubber

Sheet rubber is widely used in applications such as gaskets, seals, automotive parts, and industrial flooring due to its uniform thickness and ease of cutting into custom shapes. It offers excellent flexibility and resistance to abrasion, making it suitable for protective coatings and padding in machinery. Your projects benefit from sheet rubber's consistent quality and adaptability in both commercial and residential settings.

Popular Uses for Rolled Rubber

Rolled rubber is widely used in applications requiring consistent thickness and flexibility, such as flooring, conveyor belts, and industrial gaskets. It offers ease of installation for large surface areas, making it ideal for gym mats, automotive parts, and soundproofing materials. Your projects benefit from its durability and ability to conform to complex shapes while maintaining performance under pressure.

Durability and Performance Comparison

Sheet rubber offers superior durability due to its uniform thickness and density, making it ideal for heavy-duty applications requiring consistent performance. Rolled rubber provides flexibility and ease of installation but may have variable thickness, which can affect its long-term resilience under stress. Your choice between sheet and rolled rubber should depend on the specific durability and performance requirements of your project.

Installation Methods: Sheet Rubber vs Rolled Rubber

Sheet rubber installation involves precise cutting and fitting, making it ideal for smaller, customized areas with complex shapes or seams. Rolled rubber is typically unrolled and laid out over large surfaces, suitable for extensive floor spaces requiring fast, continuous coverage. Both methods require adhesive or mechanical fastening, but sheet rubber demands more detailed preparation to ensure seamless attachment.

Cost Considerations and Budgeting

Sheet rubber generally offers lower upfront costs due to its simpler manufacturing process and ease of handling, making it a cost-effective choice for small to medium-sized projects. Rolled rubber, while often more expensive initially, provides better coverage efficiency and reduced installation time, which can lead to overall savings in large-scale or commercial applications. Budgeting should account for factors such as project size, application requirements, and long-term durability to determine the most cost-effective rubber solution.

Selecting the Right Rubber Format for Your Project

Selecting the right rubber format for your project depends on the specific application requirements and material characteristics. Sheet rubber offers versatility and easy customization for smaller, irregular cuts, while rolled rubber provides efficiency and cost-effectiveness for large-scale, uniform installations. Your choice between sheet rubber and rolled rubber impacts installation speed, waste generation, and overall project budget.

Sheet rubber vs Rolled rubber Infographic

libmatt.com

libmatt.com