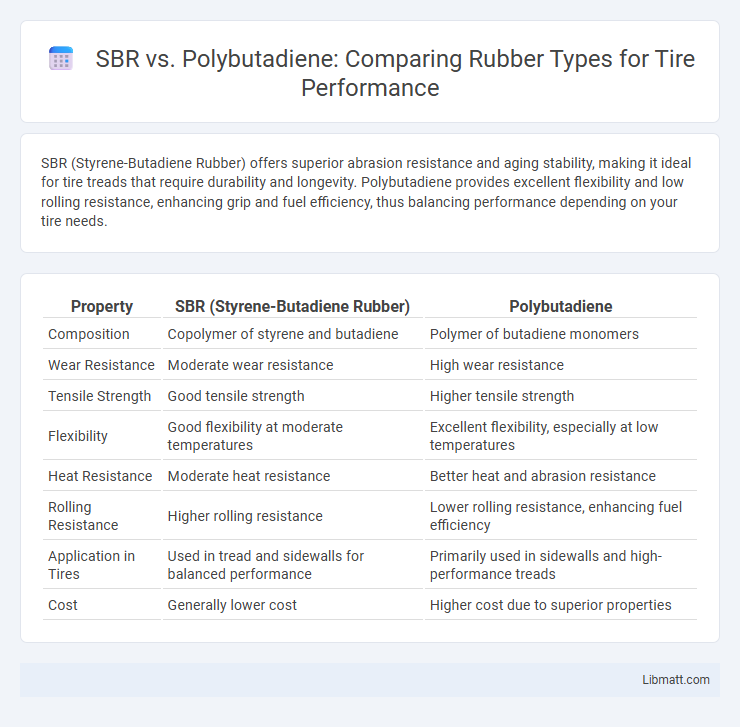

SBR (Styrene-Butadiene Rubber) offers superior abrasion resistance and aging stability, making it ideal for tire treads that require durability and longevity. Polybutadiene provides excellent flexibility and low rolling resistance, enhancing grip and fuel efficiency, thus balancing performance depending on your tire needs.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | Polybutadiene |

|---|---|---|

| Composition | Copolymer of styrene and butadiene | Polymer of butadiene monomers |

| Wear Resistance | Moderate wear resistance | High wear resistance |

| Tensile Strength | Good tensile strength | Higher tensile strength |

| Flexibility | Good flexibility at moderate temperatures | Excellent flexibility, especially at low temperatures |

| Heat Resistance | Moderate heat resistance | Better heat and abrasion resistance |

| Rolling Resistance | Higher rolling resistance | Lower rolling resistance, enhancing fuel efficiency |

| Application in Tires | Used in tread and sidewalls for balanced performance | Primarily used in sidewalls and high-performance treads |

| Cost | Generally lower cost | Higher cost due to superior properties |

Introduction to Tire Rubber Compounds

SBR (Styrene-Butadiene Rubber) and Polybutadiene are essential tire rubber compounds, each contributing unique properties to tire performance and durability. SBR offers excellent abrasion resistance and aging stability, improving traction and tread wear, while Polybutadiene enhances elasticity and impact resistance, optimizing ride comfort and reducing rolling resistance. Understanding Your tire's rubber composition helps in selecting the right balance for safer, longer-lasting tires.

What is SBR?

Styrene-Butadiene Rubber (SBR) is a synthetic polymer commonly used in tire manufacturing due to its excellent abrasion resistance and aging stability. It consists of styrene and butadiene monomers, providing a balance of durability, flexibility, and cost-effectiveness compared to natural rubber and other synthetic alternatives like polybutadiene. SBR enhances tire performance by improving traction, wear resistance, and overall lifespan, making it a preferred material for passenger car and truck tires.

Understanding Polybutadiene Rubber

Polybutadiene rubber (BR) is a synthetic elastomer prized in tire manufacturing for its exceptional abrasion resistance and low rolling resistance, enhancing tire durability and fuel efficiency. Compared to styrene-butadiene rubber (SBR), polybutadiene provides superior impact strength and wear resistance, making it ideal for high-performance tires. Your tires benefit from polybutadiene's ability to maintain flexibility in varying temperatures, improving overall traction and safety.

Key Differences Between SBR and Polybutadiene

SBR (Styrene-Butadiene Rubber) offers superior abrasion resistance and aging stability compared to Polybutadiene, making it ideal for tire treads with enhanced wear and durability. Polybutadiene provides higher elasticity and lower rolling resistance, improving fuel efficiency and ride comfort in tires. The combination of SBR's strong grip and Polybutadiene's elasticity often results in optimized tire performance for diverse driving conditions.

Performance Characteristics in Tires

SBR (Styrene-Butadiene Rubber) offers superior abrasion resistance and aging stability, making it ideal for passenger car tires that require durability and extended tread life. Polybutadiene excels in providing high resilience and low rolling resistance, enhancing fuel efficiency and traction in high-performance and racing tires. Both materials are often blended to balance wear resistance, wet traction, and overall tire performance for diverse driving conditions.

Durability and Longevity Comparison

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and aging properties, making it highly durable for standard tire applications. Polybutadiene provides superior wear resistance and flexibility, enhancing tire longevity by reducing tread cracking and improving impact resilience. Your choice between SBR and Polybutadiene depends on the balance needed between cost efficiency and maximum tire life performance.

Wet and Dry Traction Analysis

Styrene-Butadiene Rubber (SBR) offers superior wet traction in tires due to its excellent abrasion resistance and flexibility, enhancing grip on wet surfaces. Polybutadiene excels in dry traction because of its high resilience and low heat buildup, providing better performance and durability under dry conditions. Combining SBR and Polybutadiene in tire compounds optimizes both wet and dry traction, improving overall tire safety and longevity.

Rolling Resistance and Fuel Efficiency

SBR (Styrene-Butadiene Rubber) offers lower rolling resistance compared to Polybutadiene, enhancing fuel efficiency in tires due to its balanced polymer composition that reduces energy loss during rotation. Polybutadiene provides superior wear resistance but tends to increase rolling resistance, resulting in slightly higher fuel consumption. Choosing SBR tires can improve your vehicle's fuel economy by minimizing rolling resistance without compromising durability.

Environmental Impact and Sustainability

SBR (Styrene-Butadiene Rubber) and Polybutadiene both serve as essential materials in tire manufacturing, with SBR offering better abrasion resistance and Polybutadiene providing superior wear and heat resistance. From an environmental impact perspective, SBR's production is often associated with higher greenhouse gas emissions due to its petrochemical origins, while advances in bio-based Polybutadiene aim to reduce reliance on fossil fuels and improve sustainability. Your choice between these materials impacts tire recyclability and carbon footprint, with ongoing innovations targeting more eco-friendly formulations for both rubbers.

Choosing the Right Rubber for Tire Applications

Selecting between Styrene-Butadiene Rubber (SBR) and Polybutadiene (BR) for tire manufacturing depends on performance criteria such as wear resistance and rolling resistance. SBR offers excellent abrasion resistance and good aging properties, making it ideal for tread compounds requiring durability on various road surfaces. Polybutadiene enhances tire flexibility and lower rolling resistance, improving fuel efficiency and impact resistance, often used in combination with SBR to balance performance and cost.

SBR vs Polybutadiene in Tires Infographic

libmatt.com

libmatt.com