Chemical resistance measures a material's ability to withstand a variety of harsh substances such as acids, alkalis, and solvents, ensuring durability in diverse environments. Oil resistance specifically refers to how well a material can resist degradation when exposed to oils and lubricants, which is essential for applications involving machinery and automotive parts.

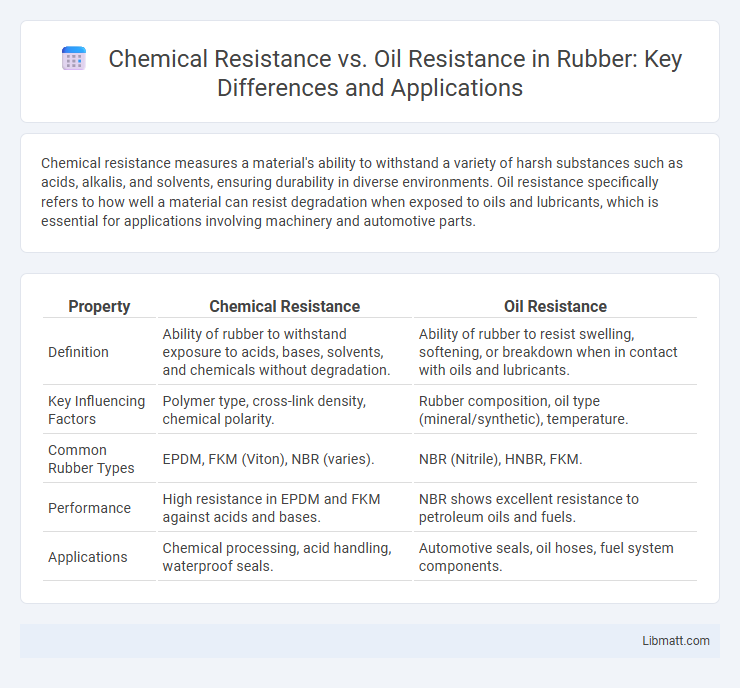

Table of Comparison

| Property | Chemical Resistance | Oil Resistance |

|---|---|---|

| Definition | Ability of rubber to withstand exposure to acids, bases, solvents, and chemicals without degradation. | Ability of rubber to resist swelling, softening, or breakdown when in contact with oils and lubricants. |

| Key Influencing Factors | Polymer type, cross-link density, chemical polarity. | Rubber composition, oil type (mineral/synthetic), temperature. |

| Common Rubber Types | EPDM, FKM (Viton), NBR (varies). | NBR (Nitrile), HNBR, FKM. |

| Performance | High resistance in EPDM and FKM against acids and bases. | NBR shows excellent resistance to petroleum oils and fuels. |

| Applications | Chemical processing, acid handling, waterproof seals. | Automotive seals, oil hoses, fuel system components. |

Understanding Chemical Resistance: Definition and Importance

Chemical resistance refers to a material's ability to withstand degradation or damage when exposed to various chemicals, including acids, bases, solvents, and oils. It is crucial in selecting materials for industrial applications where exposure to aggressive substances can compromise durability and safety. Understanding your material's chemical resistance ensures optimal performance and longevity in harsh environments.

What is Oil Resistance? Key Characteristics

Oil resistance refers to a material's ability to withstand degradation or damage when exposed to oils, including mineral and synthetic oils commonly found in automotive and industrial environments. Key characteristics include low permeability, chemical inertness to hydrocarbons, and preservation of mechanical properties such as flexibility and tensile strength under prolonged oil exposure. Your selection of oil-resistant materials ensures durability and reliability in applications where oil contact is frequent or unavoidable.

Comparing Chemical Resistance and Oil Resistance

Chemical resistance measures a material's ability to withstand exposure to a broad range of chemicals such as acids, solvents, and alkalis without degrading. Oil resistance specifically evaluates how well a material resists breakdown or swelling when exposed to various oils, including mineral, synthetic, or vegetable oils. Your choice between chemical resistance and oil resistance depends on the environmental conditions and substances the material will encounter, ensuring optimal durability and performance.

Common Materials with High Chemical Resistance

Common materials with high chemical resistance include polytetrafluoroethylene (PTFE), polyethylene (PE), polypropylene (PP), and fluoroelastomers such as Viton. These materials exhibit excellent resistance to a wide range of aggressive chemicals, including acids, bases, and solvents, making them ideal for industrial applications requiring durability in harsh environments. Their molecular structures provide low permeability and high stability, distinguishing their performance in chemical resistance from oil resistance, which often requires different polymer properties.

Top Materials Known for Oil Resistance

Fluoropolymers such as PTFE and FKM (Viton) are top materials renowned for exceptional oil resistance due to their non-polar molecular structure that repels hydrocarbons. Nitrile rubber (NBR) offers high resistance to petroleum-based oils and fuels, making it widely used in automotive and industrial seals. Polyurethane also demonstrates strong oil resistance combined with durability and abrasion resistance, suitable for demanding applications exposed to oils.

Application Areas: Chemical Resistance vs Oil Resistance

Chemical resistance is crucial in industries such as pharmaceuticals, agriculture, and wastewater treatment, where materials must withstand exposure to acids, bases, and solvents without degradation. Oil resistance is essential in automotive, machinery, and food processing sectors, where components encounter oils, greases, and lubricants that can cause swelling, cracking, or loss of elasticity. Selecting materials based on chemical resistance or oil resistance ensures durability and optimal performance in environments with specific chemical exposures.

Factors Affecting Chemical and Oil Resistance

Chemical and oil resistance are influenced primarily by the molecular structure and polarity of the material, which determine its interaction with various chemicals and oils. Temperature, exposure duration, and concentration of the chemical or oil also significantly affect the degradation or resistance performance. Material composition, including crosslink density and additive content, plays a crucial role in enhancing resistance to specific chemical agents and hydrocarbon-based oils.

Testing Methods for Chemical and Oil Resistance

Testing methods for chemical and oil resistance primarily include immersion testing, where materials are submerged in specific chemicals or oils for set durations to evaluate degradation, swelling, or weight change. Other techniques involve surface analysis using spectroscopy or microscopy to detect compositional or structural changes after exposure. Your material's performance in these tests ensures reliability in applications exposed to harsh chemical or oil environments.

Industry Standards and Certifications

Industry standards such as ASTM D471 and ISO 1817 establish rigorous testing protocols for chemical and oil resistance to ensure material durability under specific environmental conditions. Certifications from organizations like NSF International and UL validate product compliance with chemical exposure requirements, specifying tolerance levels for acids, bases, oils, and solvents. Understanding these certifications helps manufacturers select appropriate elastomers, coatings, and seals that meet industry benchmarks for safety and performance in chemical processing, automotive, and aerospace applications.

Selecting the Right Material for Specific Resistance Needs

Selecting the right material for specific resistance needs requires understanding the differences between chemical resistance and oil resistance, as each demands unique polymer characteristics. Materials like fluoropolymers and EPDM excel in chemical resistance due to their inert properties, whereas nitrile rubber and hydrogenated nitrile offer superior oil resistance by resisting hydrocarbon permeation. Tailoring material choice to the specific environmental exposure ensures optimal durability and performance in industrial applications.

Chemical Resistance vs Oil Resistance Infographic

libmatt.com

libmatt.com