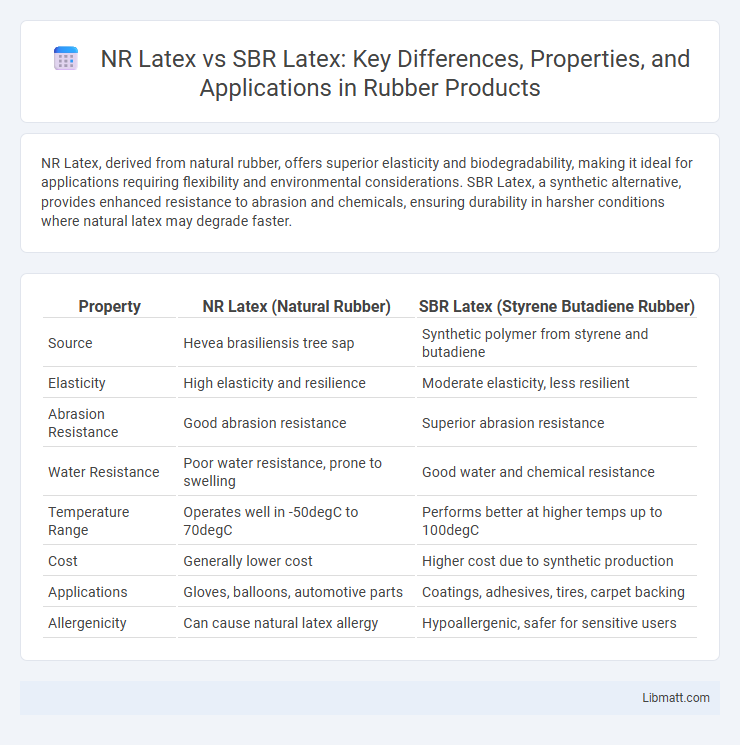

NR Latex, derived from natural rubber, offers superior elasticity and biodegradability, making it ideal for applications requiring flexibility and environmental considerations. SBR Latex, a synthetic alternative, provides enhanced resistance to abrasion and chemicals, ensuring durability in harsher conditions where natural latex may degrade faster.

Table of Comparison

| Property | NR Latex (Natural Rubber) | SBR Latex (Styrene Butadiene Rubber) |

|---|---|---|

| Source | Hevea brasiliensis tree sap | Synthetic polymer from styrene and butadiene |

| Elasticity | High elasticity and resilience | Moderate elasticity, less resilient |

| Abrasion Resistance | Good abrasion resistance | Superior abrasion resistance |

| Water Resistance | Poor water resistance, prone to swelling | Good water and chemical resistance |

| Temperature Range | Operates well in -50degC to 70degC | Performs better at higher temps up to 100degC |

| Cost | Generally lower cost | Higher cost due to synthetic production |

| Applications | Gloves, balloons, automotive parts | Coatings, adhesives, tires, carpet backing |

| Allergenicity | Can cause natural latex allergy | Hypoallergenic, safer for sensitive users |

Introduction to NR Latex and SBR Latex

NR Latex, derived from natural rubber trees, offers excellent elasticity, strength, and biodegradability, making it a preferred choice in medical gloves, balloons, and elastic textiles. SBR Latex, or Styrene-Butadiene Rubber Latex, is a synthetic alternative known for its superior abrasion resistance and ageing stability, commonly used in industrial applications like footwear and automotive components. Understanding the distinct properties of NR Latex and SBR Latex helps you select the right material for specific performance and durability needs.

Chemical Composition and Structure

NR Latex, derived from natural rubber, consists of cis-1,4-polyisoprene with a highly elastic polymeric structure, offering superior tensile strength and flexibility. SBR Latex, a synthetic rubber composed primarily of styrene and butadiene monomers, features a more amorphous polymer structure that enhances abrasion resistance and aging stability. The natural polymeric chains of NR provide excellent elasticity, while the synthetic copolymer configuration of SBR improves chemical resistance and durability.

Source and Manufacturing Process

NR Latex is derived from natural rubber harvested from Hevea brasiliensis trees through a tapping process that extracts sap-like liquid latex. SBR Latex, or Styrene-Butadiene Rubber latex, is a synthetic polymer produced via emulsion polymerization of styrene and butadiene monomers in controlled chemical reactors. The natural origin of NR Latex results in superior elasticity and biodegradability, whereas SBR Latex's petrochemical-based production offers enhanced abrasion resistance and chemical stability.

Physical and Mechanical Properties

NR Latex offers superior elasticity, tensile strength, and tear resistance due to its natural rubber composition, making it ideal for applications requiring high durability and flexibility. SBR Latex, a synthetic alternative, provides better resistance to abrasion, aging, and chemical exposure but generally has lower elasticity and tensile strength compared to NR Latex. Your choice between NR Latex and SBR Latex will depend on the balance needed between mechanical performance and environmental resistance for your specific application.

Performance in Industrial Applications

NR Latex offers superior elasticity, tensile strength, and resilience, making it ideal for high-performance industrial applications such as gloves, adhesives, and coatings. SBR Latex provides excellent abrasion resistance and cost-effectiveness, suitable for applications like flooring, carpet backing, and automotive components. Your choice depends on whether you prioritize durability and flexibility (NR) or wear resistance and affordability (SBR).

Environmental Impact and Sustainability

NR Latex, sourced from natural rubber trees, offers a renewable and biodegradable option with a lower carbon footprint compared to synthetic SBR Latex, which is derived from petrochemicals. SBR Latex production involves higher energy consumption and generates more greenhouse gases, contributing to environmental concerns. Choosing NR Latex supports your commitment to sustainability by reducing reliance on non-renewable resources and minimizing environmental impact.

Comparative Cost Analysis

NR latex, derived from natural rubber, typically incurs higher production costs due to raw material sourcing and sustainable harvesting, impacting its market price. SBR latex, a synthetic alternative made from styrene and butadiene monomers, offers a cost-effective solution with more stable pricing influenced by petrochemical market fluctuations. Cost analysis reveals NR latex is preferred for premium applications requiring elasticity and resilience, while SBR latex dominates budget-sensitive industries due to its affordability and consistent supply.

Advantages and Limitations of NR Latex

NR latex, derived from natural rubber trees, offers superior elasticity, excellent tensile strength, and biodegradability, making it ideal for medical gloves and eco-friendly products. Its limitations include sensitivity to heat, reduced shelf life, and potential allergenic reactions in some users. Compared to SBR latex, NR latex provides better abrasion resistance but is less resistant to chemicals and weathering.

Advantages and Limitations of SBR Latex

SBR latex offers enhanced chemical resistance, superior abrasion resistance, and cost-effectiveness compared to NR latex, making it ideal for industrial applications like adhesives, paints, and sealants. However, SBR latex has lower elasticity and reduced water resistance relative to NR latex, limiting its performance in products requiring high stretchability and moisture durability. Its longer curing time and inferior aging properties also restrict its use in applications demanding superior durability and flexibility.

Choosing Between NR and SBR Latex: Key Factors

Choosing between NR (Natural Rubber) latex and SBR (Styrene-Butadiene Rubber) latex depends on factors such as elasticity, resistance, and application environment. NR latex offers superior elasticity and tensile strength, making it ideal for products like gloves and balloons that require flexibility and durability. In contrast, SBR latex provides better abrasion resistance, aging stability, and chemical resistance, suited for industrial applications and products exposed to harsh conditions.

NR Latex vs SBR Latex Infographic

libmatt.com

libmatt.com