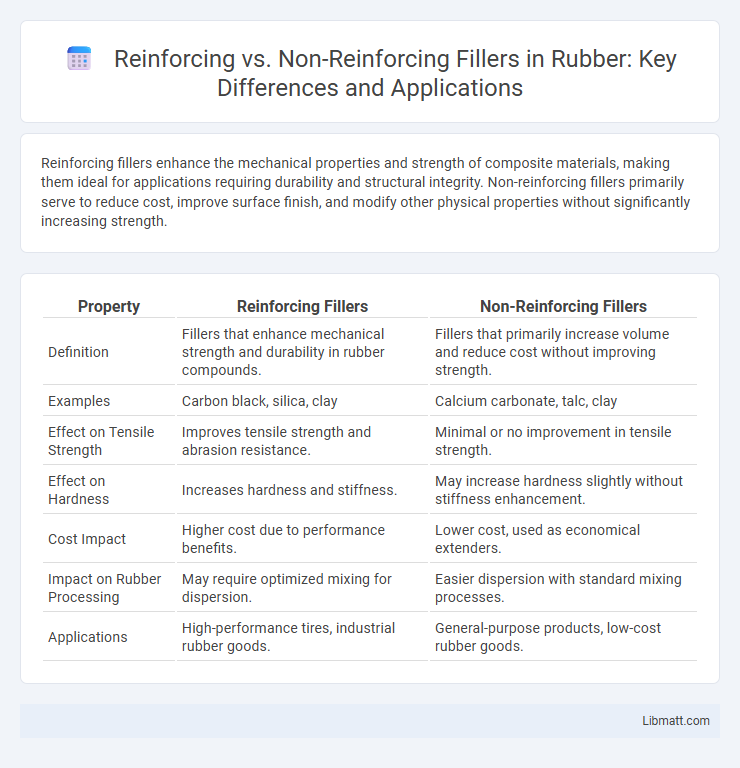

Reinforcing fillers enhance the mechanical properties and strength of composite materials, making them ideal for applications requiring durability and structural integrity. Non-reinforcing fillers primarily serve to reduce cost, improve surface finish, and modify other physical properties without significantly increasing strength.

Table of Comparison

| Property | Reinforcing Fillers | Non-Reinforcing Fillers |

|---|---|---|

| Definition | Fillers that enhance mechanical strength and durability in rubber compounds. | Fillers that primarily increase volume and reduce cost without improving strength. |

| Examples | Carbon black, silica, clay | Calcium carbonate, talc, clay |

| Effect on Tensile Strength | Improves tensile strength and abrasion resistance. | Minimal or no improvement in tensile strength. |

| Effect on Hardness | Increases hardness and stiffness. | May increase hardness slightly without stiffness enhancement. |

| Cost Impact | Higher cost due to performance benefits. | Lower cost, used as economical extenders. |

| Impact on Rubber Processing | May require optimized mixing for dispersion. | Easier dispersion with standard mixing processes. |

| Applications | High-performance tires, industrial rubber goods. | General-purpose products, low-cost rubber goods. |

Introduction to Fillers in Material Science

Fillers in material science are particulate additives incorporated into polymers to enhance or modify properties such as strength, stiffness, and cost-effectiveness. Reinforcing fillers like carbon black and glass fibers improve mechanical performance by increasing tensile strength and impact resistance, while non-reinforcing fillers such as calcium carbonate and talc primarily reduce material cost and modify density without significant strength enhancement. The choice between reinforcing and non-reinforcing fillers directly influences the composite's physical behavior, processing characteristics, and application suitability.

Definition of Reinforcing Fillers

Reinforcing fillers are materials added to polymers to enhance mechanical properties such as strength, stiffness, and impact resistance by creating strong interfacial bonds with the matrix. Common reinforcing fillers include carbon black, silica, and glass fibers, which improve durability and performance in applications like automotive parts and construction materials. Your choice of reinforcing fillers directly influences the composite's load-bearing capacity and overall structural integrity.

Definition of Non-reinforcing Fillers

Non-reinforcing fillers are inert substances added to polymer matrices to reduce cost and modify physical properties without significantly enhancing mechanical strength or stiffness. Common examples include calcium carbonate, talc, and clay, which improve density, hardness, and surface finish but do not contribute to load-bearing capacity. The key characteristic of non-reinforcing fillers is their limited interaction with the polymer matrix, resulting in negligible impact on tensile strength and impact resistance.

Key Differences Between Reinforcing and Non-reinforcing Fillers

Reinforcing fillers, such as carbon black and silica, enhance mechanical properties like tensile strength and abrasion resistance, making them ideal for rubber and plastic applications requiring durability. Non-reinforcing fillers, including calcium carbonate and talc, primarily reduce cost and improve processing without significantly increasing strength or stiffness. Your choice between these fillers depends on the desired balance of performance and cost efficiency in the final product.

Common Types of Reinforcing Fillers

Common types of reinforcing fillers include silica, carbon black, glass fibers, and clay, each significantly enhancing the mechanical properties of polymers. Silica improves tensile strength and abrasion resistance, while carbon black enhances durability and UV resistance, making them essential in tire and rubber manufacturing. Glass fibers increase stiffness and impact resistance, often used in composites for automotive and construction applications.

Popular Examples of Non-reinforcing Fillers

Non-reinforcing fillers such as calcium carbonate, talc, and clay are commonly used to enhance volume, reduce costs, and improve surface finish without significantly increasing the mechanical strength of composites. These fillers improve processing characteristics and dimensional stability while maintaining lightweight properties, making them ideal for applications where strength enhancement is not critical. Understanding the role of non-reinforcing fillers can help you optimize material properties for cost-effective manufacturing in industries like packaging, automotive interior components, and consumer goods.

Impact on Mechanical Properties

Reinforcing fillers like carbon black and silica significantly enhance the mechanical properties of materials by improving tensile strength, stiffness, and abrasion resistance. Non-reinforcing fillers such as calcium carbonate and talc mainly act as cost reducers and volume enhancers but typically reduce overall mechanical strength and elasticity. Your choice of filler directly influences the durability and performance of the composite material in applications requiring high mechanical integrity.

Applications in Industry

Reinforcing fillers like carbon black and silica enhance the mechanical strength and durability of rubber and plastic products, making them essential in automotive tires, construction materials, and heavy-duty equipment. Non-reinforcing fillers such as calcium carbonate and talc primarily reduce production costs and improve processing efficiency in applications like packaging, adhesives, and coatings. Your choice between these fillers depends on the required performance properties and economic considerations in specific industrial applications.

Factors Influencing Filler Performance

Filler performance is influenced by factors such as particle size, shape, and surface area, which affect the interaction between fillers and the polymer matrix. Reinforcing fillers typically have high surface energy and strong adhesion to the matrix, enhancing mechanical properties like tensile strength and durability. Non-reinforcing fillers often have larger particle sizes and lower surface activity, serving primarily to reduce cost and modify density without significantly improving mechanical performance.

Future Trends in Filler Technology

Future trends in filler technology focus on developing advanced reinforcing fillers like carbon nanotubes and graphene to enhance polymer composites' mechanical strength and thermal stability. Non-reinforcing fillers are being optimized for improved cost efficiency and specific functional properties such as UV resistance and electrical insulation. Innovations aim to combine nano-scale fillers with sustainable materials, promoting lightweight, high-performance composites for automotive and aerospace industries.

Reinforcing vs Non-reinforcing fillers Infographic

libmatt.com

libmatt.com