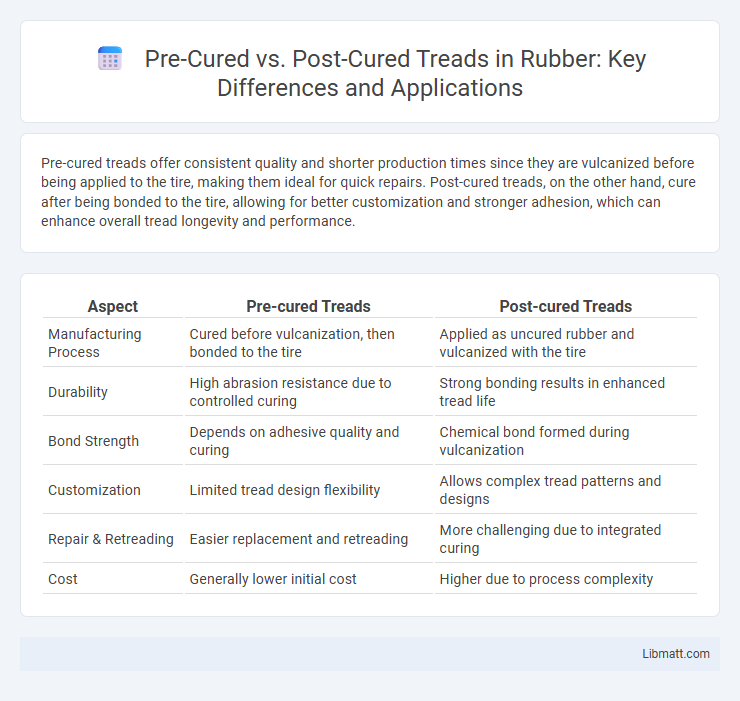

Pre-cured treads offer consistent quality and shorter production times since they are vulcanized before being applied to the tire, making them ideal for quick repairs. Post-cured treads, on the other hand, cure after being bonded to the tire, allowing for better customization and stronger adhesion, which can enhance overall tread longevity and performance.

Table of Comparison

| Aspect | Pre-cured Treads | Post-cured Treads |

|---|---|---|

| Manufacturing Process | Cured before vulcanization, then bonded to the tire | Applied as uncured rubber and vulcanized with the tire |

| Durability | High abrasion resistance due to controlled curing | Strong bonding results in enhanced tread life |

| Bond Strength | Depends on adhesive quality and curing | Chemical bond formed during vulcanization |

| Customization | Limited tread design flexibility | Allows complex tread patterns and designs |

| Repair & Retreading | Easier replacement and retreading | More challenging due to integrated curing |

| Cost | Generally lower initial cost | Higher due to process complexity |

Introduction to Pre-cured and Post-cured Treads

Pre-cured treads are rubber components vulcanized before being applied to tire casings, allowing precise quality control and consistent performance. Post-cured treads undergo the vulcanization process after being assembled with the tire carcass, offering enhanced bonding and flexibility in design modifications. Both methods impact tire durability, wear resistance, and manufacturing efficiency, crucial factors in tire retreading technology.

Understanding the Tread Retreading Process

Pre-cured treads involve applying pre-vulcanized rubber treads onto a prepared casing, allowing faster processing and reduced curing time during retreading. Post-cured treads use uncured rubber that is molded and vulcanized onto the tire casing simultaneously, offering a stronger bond but requiring longer curing cycles. Understanding your specific needs for durability, turnaround time, and performance helps determine the best tread retreading process for optimal tire life.

What Are Pre-cured Treads?

Pre-cured treads are rubber strips that have already been vulcanized before being applied to tire casings, ensuring uniformity and consistent quality. These treads are typically manufactured in controlled environments, allowing for precise thickness and tread patterns that enhance grip and durability. Using pre-cured treads reduces curing time during retreading, improving workflow efficiency and minimizing the risk of defects.

What Are Post-cured Treads?

Post-cured treads undergo an additional curing process after being applied to the tire, enhancing their durability and adhesion. This secondary curing improves the tread's resistance to wear, heat, and environmental conditions, resulting in longer-lasting performance. Post-cured treads are commonly used in retreading applications where high-quality and extended tire life are critical.

Key Differences Between Pre-cured and Post-cured Treads

Pre-cured treads are manufactured by vulcanizing the tread separately before applying it to the tire casing, resulting in consistent quality and reduced curing time during retreading. Post-cured treads, on the other hand, are applied as uncured rubber and vulcanized directly onto the tire casing, ensuring a strong bond and better conformity to the casing shape. Understanding these key differences helps you choose the right retreading method based on performance needs, cost considerations, and production efficiency.

Advantages of Pre-cured Tread Retreading

Pre-cured tread retreading offers advantages such as reduced curing time and enhanced process control, resulting in consistent tread quality and improved tire performance. The use of pre-vulcanized tread strips minimizes the risk of defects, enabling faster turnaround and cost-effective production for commercial tire retreading. This method also ensures uniform tread thickness, prolonging tire lifespan and providing better traction for various vehicle applications.

Advantages of Post-cured Tread Retreading

Post-cured tread retreading offers enhanced durability and improved tire performance by allowing precise control over the curing process, resulting in superior tread adhesion and longevity. This method reduces the risk of tread separation and provides a smoother, more consistent tread surface, which enhances safety and fuel efficiency. Your fleet benefits from lower maintenance costs and extended tire life, making post-cured retreads a cost-effective solution for heavy-duty vehicles.

Cost Comparison: Pre-cured vs Post-cured Treads

Pre-cured treads typically involve higher upfront costs due to the advanced manufacturing process but offer savings in application time and labor, making them cost-effective for large-scale projects. Post-cured treads may have lower initial material expenses but often incur additional costs from extended curing times and increased labor, potentially raising overall project expenses. Your choice between pre-cured and post-cured treads should consider both material costs and installation efficiency to optimize budget and performance.

Applications and Suitability for Various Vehicles

Pre-cured treads are ideal for light passenger vehicles and low-speed applications due to their ease of installation and consistent quality, while post-cured treads offer superior durability and are suited for heavy-duty trucks and off-road vehicles requiring enhanced tread strength. Your choice between pre-cured and post-cured treads should consider vehicle type, operating conditions, and desired tire lifespan. Post-cured treads provide better adhesion and resistance in demanding environments, making them preferable for commercial and industrial vehicles.

Choosing the Best Tread Retreading Method

Pre-cured treads feature vulcanized rubber tread strips that are bonded to the tire casing, offering quicker installation and consistent quality, whereas post-cured treads involve applying uncured rubber to the casing and curing the tread and casing together for a more customized fit. Your choice between pre-cured and post-cured retreading depends on factors like turnaround time, budget, tire type, and application needs. Selecting the best method ensures optimal tread durability, performance, and cost-effectiveness tailored to your specific vehicle requirements.

Pre-cured vs Post-cured treads Infographic

libmatt.com

libmatt.com