Open cell sponge features interconnected pores that allow water and air to pass through easily, providing excellent cushioning and breathability; closed cell sponge has tightly packed cells that offer superior water resistance and durability, making it ideal for insulation and flotation purposes. Your choice depends on whether you need softness and absorption from open cell or rigidity and waterproof properties from closed cell material.

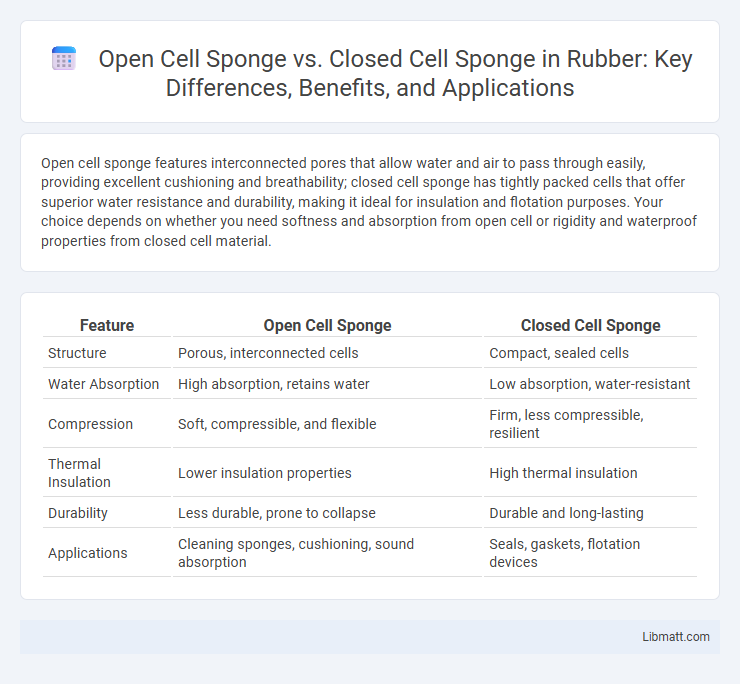

Table of Comparison

| Feature | Open Cell Sponge | Closed Cell Sponge |

|---|---|---|

| Structure | Porous, interconnected cells | Compact, sealed cells |

| Water Absorption | High absorption, retains water | Low absorption, water-resistant |

| Compression | Soft, compressible, and flexible | Firm, less compressible, resilient |

| Thermal Insulation | Lower insulation properties | High thermal insulation |

| Durability | Less durable, prone to collapse | Durable and long-lasting |

| Applications | Cleaning sponges, cushioning, sound absorption | Seals, gaskets, flotation devices |

Introduction to Open Cell and Closed Cell Sponges

Open cell sponges feature interconnected pores that allow air and moisture to pass through, making them highly absorbent and flexible for applications such as cushioning and cleaning. Closed cell sponges consist of tightly packed, sealed cells that prevent air and water infiltration, providing superior rigidity, insulation, and buoyancy for uses in flotation devices and insulation panels. Understanding the structural differences between open cell and closed cell sponges is crucial for selecting the right material based on absorption, durability, and thermal resistance requirements.

Defining Open Cell Sponge

Open cell sponge consists of interconnected pores that allow air and water to pass through easily, making it highly breathable and absorbent. This structure makes it ideal for applications requiring cushioning, filtration, and sound absorption. Your choice between open cell and closed cell depends on whether you prioritize moisture permeability or water resistance.

Defining Closed Cell Sponge

Closed cell sponge is a type of foam characterized by tightly packed, sealed cells that prevent air and water from passing through, making it highly resistant to moisture, chemicals, and compression. Unlike open cell sponge, closed cell sponge provides superior insulation, buoyancy, and durability, commonly used in applications requiring waterproof and cushioning properties. Its dense structure ensures long-lasting performance in marine, automotive, and industrial sealing tasks.

Key Differences Between Open Cell and Closed Cell Sponges

Open cell sponges feature interconnected pores that allow air and water to flow through, making them highly absorbent and flexible, ideal for cleaning and cushioning applications. Closed cell sponges consist of sealed, individual pockets filled with gas, providing superior buoyancy, rigidity, and resistance to water absorption, perfect for insulation and flotation devices. Your choice between open cell and closed cell sponges depends on whether you need maximum absorption or structural stability.

Material Composition and Structure

Open cell sponges feature a porous structure made from polyurethane or melamine, allowing air and water to penetrate easily, which enhances absorption and flexibility. Closed cell sponges consist of a dense, airtight foam, often composed of polyethylene or neoprene, providing superior water resistance and durability due to their sealed cell walls. The distinct differences in material composition and cellular structure directly impact their functional applications in cleaning, insulation, and cushioning.

Absorption and Water Retention Properties

Open cell sponges have a porous structure that allows for high absorption and excellent water retention, making them ideal for cleaning and cushioning applications where moisture needs to be absorbed quickly. Closed cell sponges have a dense, non-porous structure that resists water absorption, providing superior buoyancy and durability in wet environments while preventing water retention. These distinct properties determine their effectiveness in applications requiring either rapid water uptake or water resistance.

Durability and Lifespan

Closed cell sponges exhibit superior durability and a longer lifespan compared to open cell sponges due to their dense, non-porous structure that resists water absorption and compression. Open cell sponges are more prone to wear and tear as their interconnected pores allow moisture and debris to accumulate, accelerating material degradation. For applications requiring extended use and robustness, closed cell sponges provide enhanced resistance to environmental factors and mechanical stress.

Common Applications of Each Sponge Type

Open cell sponges are widely used in cleaning tasks, air and water filtration, and cushioning in packaging due to their porous structure allowing fluid and air flow. Closed cell sponges excel in insulation, flotation devices, and sealing applications because their dense, water-resistant nature prevents liquid absorption. Selecting between open and closed cell sponges depends on requirements like breathability, absorption, and durability for specific industrial or household uses.

Pros and Cons: Open Cell vs Closed Cell Sponges

Open cell sponges offer superior absorbency and softness, making them ideal for cleaning delicate surfaces, but they tend to retain moisture and dry slowly, creating a breeding ground for bacteria. Closed cell sponges provide excellent durability, water resistance, and quick drying, which prevents mold and mildew growth, yet they have lower absorbency and can be less comfortable for delicate tasks. Choosing the right sponge depends on your specific needs, balancing the open cell's cushioning and absorbency against the closed cell's toughness and hygiene benefits.

Choosing the Right Sponge for Your Needs

Open cell sponge offers superior breathability and absorbency, making it ideal for cleaning tasks or cushioning where moisture needs to pass through. Closed cell sponge provides excellent water resistance and durability, suited for insulation, flotation devices, and applications requiring resistance to compression and chemicals. Choosing the right sponge depends on whether you prioritize absorbency and softness or moisture resistance and structural integrity.

Open Cell Sponge vs Closed Cell Sponge Infographic

libmatt.com

libmatt.com