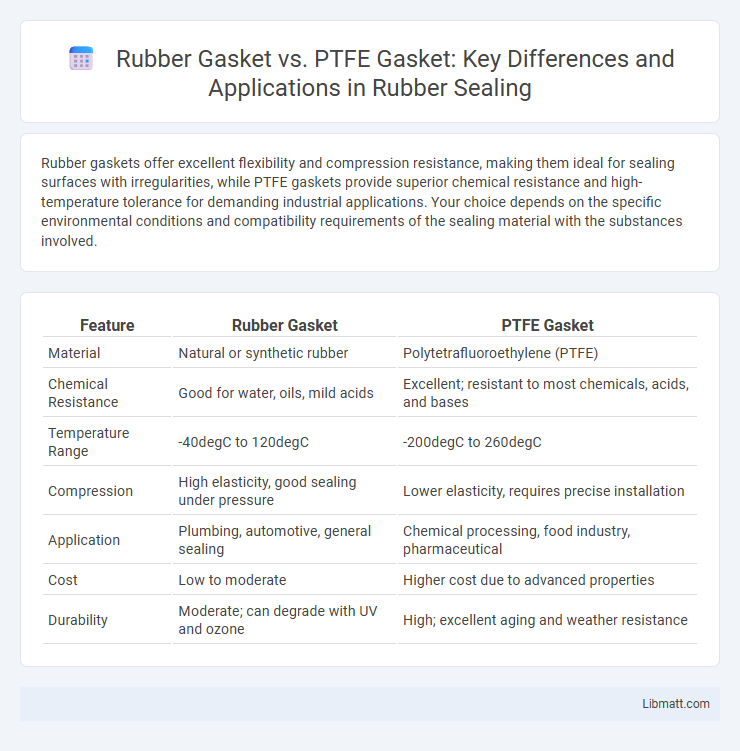

Rubber gaskets offer excellent flexibility and compression resistance, making them ideal for sealing surfaces with irregularities, while PTFE gaskets provide superior chemical resistance and high-temperature tolerance for demanding industrial applications. Your choice depends on the specific environmental conditions and compatibility requirements of the sealing material with the substances involved.

Table of Comparison

| Feature | Rubber Gasket | PTFE Gasket |

|---|---|---|

| Material | Natural or synthetic rubber | Polytetrafluoroethylene (PTFE) |

| Chemical Resistance | Good for water, oils, mild acids | Excellent; resistant to most chemicals, acids, and bases |

| Temperature Range | -40degC to 120degC | -200degC to 260degC |

| Compression | High elasticity, good sealing under pressure | Lower elasticity, requires precise installation |

| Application | Plumbing, automotive, general sealing | Chemical processing, food industry, pharmaceutical |

| Cost | Low to moderate | Higher cost due to advanced properties |

| Durability | Moderate; can degrade with UV and ozone | High; excellent aging and weather resistance |

Introduction to Rubber and PTFE Gaskets

Rubber gaskets offer excellent flexibility, chemical resistance, and sealing performance in low to moderate temperature applications, making them ideal for automotive and plumbing uses. PTFE gaskets provide superior chemical inertness, high-temperature resistance, and low friction properties, suitable for harsh chemical environments and industrial processes. Your choice between rubber and PTFE gaskets depends on the specific operational conditions and compatibility requirements of your sealing application.

Material Overview: Rubber vs PTFE

Rubber gaskets, made from natural or synthetic elastomers, offer flexibility, excellent sealing properties, and resistance to water and some chemicals, making them ideal for low to moderate temperature applications. PTFE gaskets, composed of polytetrafluoroethylene, provide superior chemical resistance, a wide temperature range tolerance from -200degC to 260degC, and low friction, suitable for highly corrosive environments. The choice between rubber and PTFE materials depends on factors like chemical exposure, temperature requirements, and mechanical stress in the intended application.

Key Applications for Rubber Gaskets

Rubber gaskets are widely used in automotive engines, plumbing systems, and HVAC equipment due to their excellent flexibility and resistance to water, oils, and mild chemicals. These gaskets provide effective sealing in dynamic environments where vibration and movement occur, making them ideal for sealing pipes, pumps, and valve assemblies. Your choice of rubber gaskets ensures reliable performance in low to medium temperature applications with moderate pressure conditions.

Key Applications for PTFE Gaskets

PTFE gaskets are essential in chemical processing, pharmaceuticals, and food industries due to their exceptional chemical resistance and non-reactive properties. Their ability to withstand high temperatures and aggressive corrosive environments makes them ideal for sealing pipes, valves, and pumps handling acids, solvents, and other hazardous substances. You can rely on PTFE gaskets to maintain a secure, leak-proof seal in applications where rubber gaskets may degrade or fail.

Chemical Resistance Comparison

Rubber gaskets offer good resistance to water, oils, and some acids but can degrade when exposed to strong solvents, hydrocarbons, or high temperatures. PTFE gaskets exhibit superior chemical resistance across a broad spectrum, including aggressive acids, bases, and solvents, making them ideal for harsh chemical environments. Choosing PTFE ensures your seal remains durable and effective under extreme chemical exposure where rubber would fail.

Temperature Tolerance of Rubber and PTFE

Rubber gaskets typically withstand temperatures ranging from -40degC to 120degC, making them suitable for moderate heat applications. PTFE gaskets exhibit superior temperature tolerance, operating effectively between -200degC and 260degC, ideal for high-temperature and chemically aggressive environments. Selecting the appropriate gasket material depends on the thermal demands of the specific application to ensure durability and seal integrity.

Durability and Longevity: Which Lasts Longer?

Rubber gaskets typically offer excellent flexibility and sealing capabilities but tend to degrade faster under high temperatures and chemical exposure, limiting their durability. PTFE gaskets, made from polytetrafluoroethylene, exhibit superior chemical resistance and can endure extreme temperatures without cracking or losing integrity, ensuring longer lifespan in demanding environments. Choosing a PTFE gasket will enhance your system's longevity due to its robust, enduring material properties.

Installation and Maintenance Considerations

Rubber gaskets offer flexibility and ease of installation, conforming well to flange surfaces, but they may require frequent inspections due to potential degradation from temperature and chemical exposure. PTFE gaskets provide superior chemical resistance and longer service life, though their installation demands careful alignment and torque control to prevent creep and blowout. Maintenance for PTFE gaskets is generally less frequent but requires specialized handling to avoid damage during removal or reinstallation.

Cost Analysis: Rubber vs PTFE Gaskets

Rubber gaskets generally offer lower initial costs compared to PTFE gaskets, making them a cost-effective choice for non-corrosive and lower temperature applications. PTFE gaskets, while more expensive upfront, provide superior chemical resistance and durability, reducing replacement frequency and long-term maintenance expenses in harsh environments. Evaluating total lifecycle costs, including installation, maintenance, and replacement, demonstrates that PTFE gaskets may deliver better value in demanding industrial settings despite their higher purchase price.

Choosing the Right Gasket for Your Application

Rubber gaskets provide excellent flexibility, chemical resistance, and are ideal for sealing in dynamic environments with moderate temperatures up to 120degC. PTFE gaskets, made from polytetrafluoroethylene, offer superior chemical inertness, high-temperature resistance up to 260degC, and are suitable for aggressive chemicals and sterilization processes. Selecting the right gasket depends on factors like temperature range, chemical exposure, pressure conditions, and mechanical stress to ensure optimal sealing performance and longevity.

Rubber Gasket vs PTFE Gasket Infographic

libmatt.com

libmatt.com