Damping rubber is designed to absorb and dissipate energy, reducing vibrations and noise in mechanical systems, whereas resilient rubber focuses on returning to its original shape quickly after deformation, providing flexibility and shock absorption. Your choice depends on whether you need to minimize vibration transmission or require elasticity for repeated compressions.

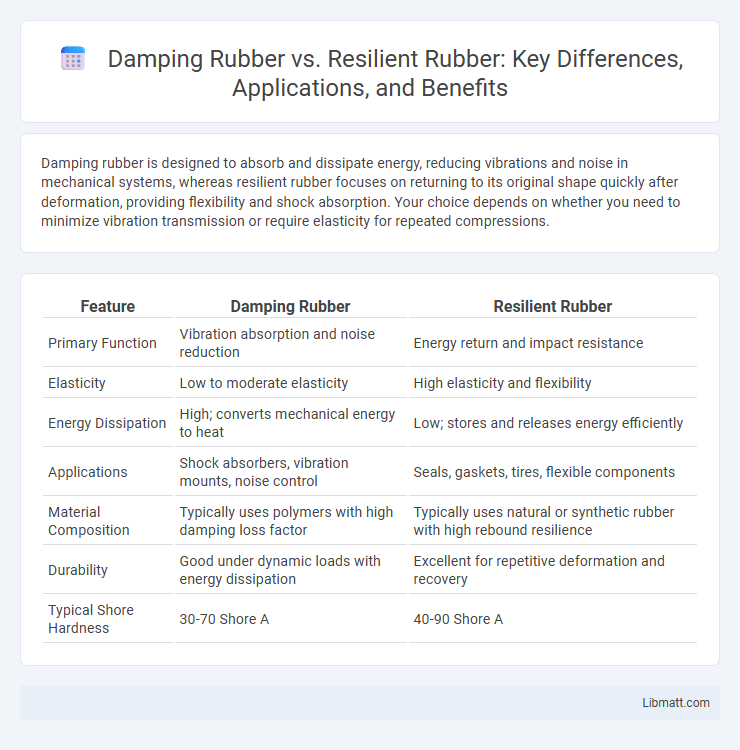

Table of Comparison

| Feature | Damping Rubber | Resilient Rubber |

|---|---|---|

| Primary Function | Vibration absorption and noise reduction | Energy return and impact resistance |

| Elasticity | Low to moderate elasticity | High elasticity and flexibility |

| Energy Dissipation | High; converts mechanical energy to heat | Low; stores and releases energy efficiently |

| Applications | Shock absorbers, vibration mounts, noise control | Seals, gaskets, tires, flexible components |

| Material Composition | Typically uses polymers with high damping loss factor | Typically uses natural or synthetic rubber with high rebound resilience |

| Durability | Good under dynamic loads with energy dissipation | Excellent for repetitive deformation and recovery |

| Typical Shore Hardness | 30-70 Shore A | 40-90 Shore A |

Introduction to Damping Rubber and Resilient Rubber

Damping rubber is engineered to absorb and dissipate vibrational energy, reducing noise and mechanical resonance in various applications such as automotive and industrial machinery. Resilient rubber, characterized by its high elasticity and ability to recover shape quickly, provides cushioning and shock absorption, commonly used in suspension systems and vibration isolators. The distinct material properties of damping rubber emphasize energy dissipation, while resilient rubber focuses on energy return and deformation recovery.

What Is Damping Rubber?

Damping rubber is a specialized elastomer designed to absorb and dissipate vibrational energy, reducing noise and mechanical resonance in automotive, industrial, and electronic applications. Unlike resilient rubber, which primarily provides cushioning and flexibility, damping rubber converts vibrational waves into heat, enhancing overall system stability and longevity. Your choice of damping rubber can significantly improve performance in environments prone to continuous or high-frequency vibrations.

What Is Resilient Rubber?

Resilient rubber is a type of elastomer designed to absorb and dissipate energy while maintaining its original shape and flexibility, making it ideal for applications requiring shock absorption and vibration isolation. Unlike damping rubber, which primarily converts mechanical energy into heat for noise reduction, resilient rubber emphasizes elasticity and rebound properties to protect structures and components from impact and deformation. Its high resilience and durability make it commonly used in automotive suspension systems, industrial mounts, and sports equipment.

Key Material Properties Compared

Damping rubber excels in energy absorption and vibration reduction due to its high hysteresis and viscoelastic properties, making it ideal for noise and shock isolation. Resilient rubber, characterized by its superior elasticity and low energy loss, provides excellent rebound and flexibility under repeated stress. Your selection depends on whether vibration dampening or material resilience is the priority, with damping rubber outperforming in attenuation and resilient rubber in durability and recovery.

Performance in Vibration Control

Damping rubber exhibits superior performance in vibration control due to its high energy dissipation capabilities, effectively reducing amplitude and frequency of vibrations. Resilient rubber provides excellent elasticity and rebound, allowing it to absorb shocks but with less energy dissipation compared to damping rubber. For applications requiring sustained vibration isolation with minimized noise, damping rubber is preferred, while resilient rubber suits scenarios demanding rapid recovery and flexibility.

Durability and Lifespan Differences

Damping rubber typically exhibits superior durability due to its enhanced ability to absorb vibrations and resist wear under dynamic loads, resulting in a longer lifespan in industrial applications. Resilient rubber, while flexible and effective at returning to its original shape, may experience faster degradation when subjected to continuous mechanical stress and environmental factors. Consequently, damping rubber is preferred in settings demanding extended service life and consistent performance under harsh operational conditions.

Applications of Damping Rubber

Damping rubber is primarily used in applications requiring vibration control and noise reduction, such as in automotive engine mounts, machinery isolation pads, and building foundations to enhance structural comfort. It absorbs and dissipates energy, reducing oscillations and protecting sensitive components from mechanical stress. Your equipment's longevity and operational stability benefit significantly from incorporating high-quality damping rubber in these industrial and engineering solutions.

Applications of Resilient Rubber

Resilient rubber is widely used in applications requiring high elasticity and energy absorption, such as vibration isolators, automotive engine mounts, and shock absorbers. Its ability to deform under stress and return to its original shape makes it ideal for preserving structural integrity in machinery and building foundations. You benefit from its durability in reducing noise and minimizing mechanical wear in dynamic environments.

Cost and Maintenance Considerations

Damping rubber generally incurs higher upfront costs due to specialized materials designed for vibration absorption, but it requires less frequent maintenance because of its enhanced durability and resistance to fatigue. Resilient rubber offers lower initial investment costs, making it suitable for budget-conscious applications, though it may demand more frequent inspections and replacements due to faster wear under continuous dynamic stress. Cost-benefit analysis should weigh initial expenditure against long-term maintenance to determine the optimal rubber type for specific operational environments.

Choosing the Right Rubber for Your Needs

Damping rubber is engineered to absorb and dissipate vibrational energy, making it ideal for applications requiring noise reduction and vibration control, such as automotive mounts and industrial machinery. Resilient rubber offers superior elasticity and quick deformation recovery, suitable for products needing impact resistance and flexibility like seals and gaskets. Selecting the right rubber depends on your specific performance requirements: prioritize damping rubber for vibration isolation and resilient rubber for durability and elasticity.

Damping Rubber vs Resilient Rubber Infographic

libmatt.com

libmatt.com