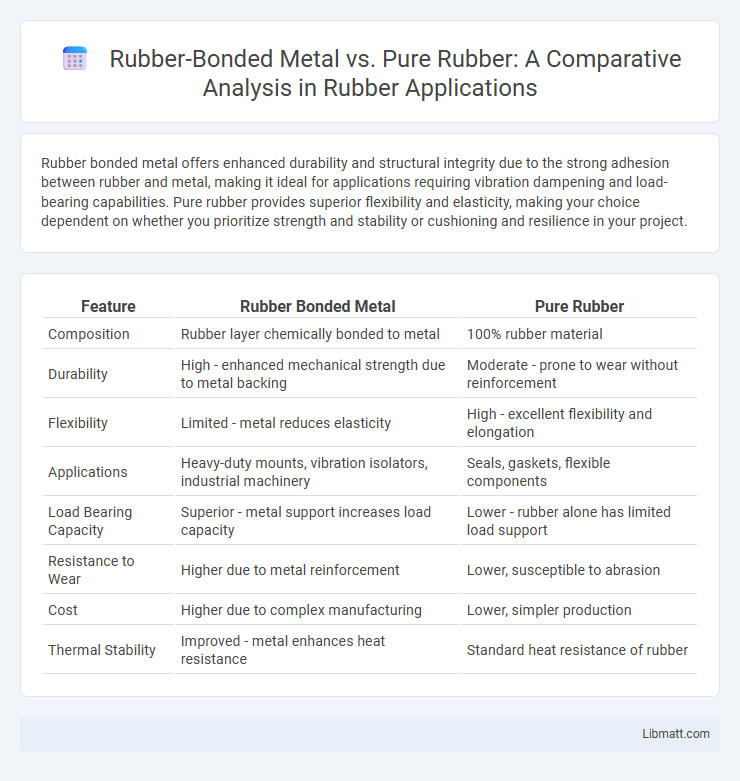

Rubber bonded metal offers enhanced durability and structural integrity due to the strong adhesion between rubber and metal, making it ideal for applications requiring vibration dampening and load-bearing capabilities. Pure rubber provides superior flexibility and elasticity, making your choice dependent on whether you prioritize strength and stability or cushioning and resilience in your project.

Table of Comparison

| Feature | Rubber Bonded Metal | Pure Rubber |

|---|---|---|

| Composition | Rubber layer chemically bonded to metal | 100% rubber material |

| Durability | High - enhanced mechanical strength due to metal backing | Moderate - prone to wear without reinforcement |

| Flexibility | Limited - metal reduces elasticity | High - excellent flexibility and elongation |

| Applications | Heavy-duty mounts, vibration isolators, industrial machinery | Seals, gaskets, flexible components |

| Load Bearing Capacity | Superior - metal support increases load capacity | Lower - rubber alone has limited load support |

| Resistance to Wear | Higher due to metal reinforcement | Lower, susceptible to abrasion |

| Cost | Higher due to complex manufacturing | Lower, simpler production |

| Thermal Stability | Improved - metal enhances heat resistance | Standard heat resistance of rubber |

Introduction to Rubber Bonded Metal and Pure Rubber

Rubber bonded metal combines the elasticity of rubber with the strength and durability of metal, offering enhanced mechanical performance and resistance to wear in industrial applications. Pure rubber, known for its high flexibility and excellent shock absorption, provides superior cushioning but lacks the structural support found in bonded metals. Understanding these materials helps you choose the right option for applications requiring a balance between flexibility and strength.

Material Composition Overview

Rubber bonded metal combines elastomeric compounds with metal substrates to enhance mechanical strength and durability, while pure rubber consists solely of polymer chains like natural rubber or synthetic variants such as EPDM or Nitrile. The metal component in bonded rubber materials typically includes steel or aluminum, which is chemically or mechanically treated to improve adhesion with the rubber layer. Pure rubber offers high elasticity and chemical resistance but lacks the structural support and load-bearing capacity provided by the integrated metal core in bonded assemblies.

Key Manufacturing Processes

Rubber bonded metal involves a specialized manufacturing process that combines vulcanization with adhesive bonding to securely attach rubber to metal substrates, enhancing durability and impact resistance. Pure rubber manufacturing typically focuses on compounding, molding, and curing processes without metal integration, allowing for greater flexibility and elasticity. The key distinction lies in the additional metal surface preparation and bonding chemicals used in rubber bonded metal production to ensure strong adhesion and structural integrity.

Mechanical Strength and Durability

Rubber bonded metal offers superior mechanical strength compared to pure rubber due to the integration of metal components, which enhances load-bearing capacity and resistance to deformation. Durability is significantly improved in rubber bonded metal products as the metal reinforcement prevents wear, extends lifespan, and reduces the risk of tearing under stress. Choosing rubber bonded metal can increase the longevity and reliability of parts in demanding mechanical applications, optimizing performance where your equipment endures heavy use.

Vibration and Noise Damping Properties

Rubber bonded metal exhibits superior vibration and noise damping properties compared to pure rubber due to the enhanced mechanical strength and rigidity provided by the metal core. This composite structure effectively absorbs and dissipates vibrational energy, reducing noise transmission in industrial applications. Your choice between the two materials should consider the specific damping requirements and environmental conditions for optimal performance.

Applications in Automotive and Industrial Sectors

Rubber bonded metal combines the elasticity of rubber with the strength of metal, making it ideal for automotive vibration dampers, engine mounts, and suspension bushings where durability and flexibility are crucial. Pure rubber, known for its excellent sealing and insulating properties, is commonly used in industrial gaskets, seals, and hoses that require high resistance to chemicals and temperature variations. The integration of metal in rubber bonded products extends application possibilities in heavy-duty environments, whereas pure rubber remains preferred for lighter, more flexible industrial components.

Cost Comparison and Economic Considerations

Rubber bonded metal typically incurs higher initial costs compared to pure rubber due to the additional metal components and complex manufacturing processes involved. However, the durability and enhanced mechanical properties of rubber bonded metal often result in lower long-term maintenance and replacement expenses, offering better economic value in applications requiring heavy load resistance. Pure rubber, while cheaper upfront, may lead to increased total cost of ownership over time due to faster wear and limited structural support.

Environmental Impact and Recyclability

Rubber bonded metal combines elastomers with metal components, complicating recycling processes due to the need for separation and potential chemical treatments, which can increase environmental impact. Pure rubber, especially natural rubber, offers better recyclability and biodegradability, reducing landfill waste and pollution. Advances in eco-friendly manufacturing for both materials aim to minimize carbon footprint and improve lifecycle sustainability.

Performance Under Extreme Conditions

Rubber bonded metal exhibits superior durability and resistance to wear under extreme temperatures and high mechanical stress compared to pure rubber, making it ideal for heavy-duty industrial applications. The metal reinforcement enhances load-bearing capacity and minimizes deformation, ensuring consistent performance in harsh environments like automotive engine mounts and heavy machinery components. Pure rubber, while flexible and resilient, tends to degrade faster when exposed to extreme heat, cold, or chemicals, limiting its effectiveness in demanding conditions.

Choosing the Right Material for Your Needs

Rubber bonded metal offers enhanced durability and vibration resistance compared to pure rubber, making it ideal for heavy-duty industrial applications where mechanical strength is crucial. Pure rubber provides excellent flexibility and elasticity, suitable for sealing and cushioning tasks requiring high resilience and chemical resistance. Assess your specific requirements for load-bearing capacity and environmental exposure to choose the right material for your needs.

Rubber Bonded Metal vs Pure Rubber Infographic

libmatt.com

libmatt.com