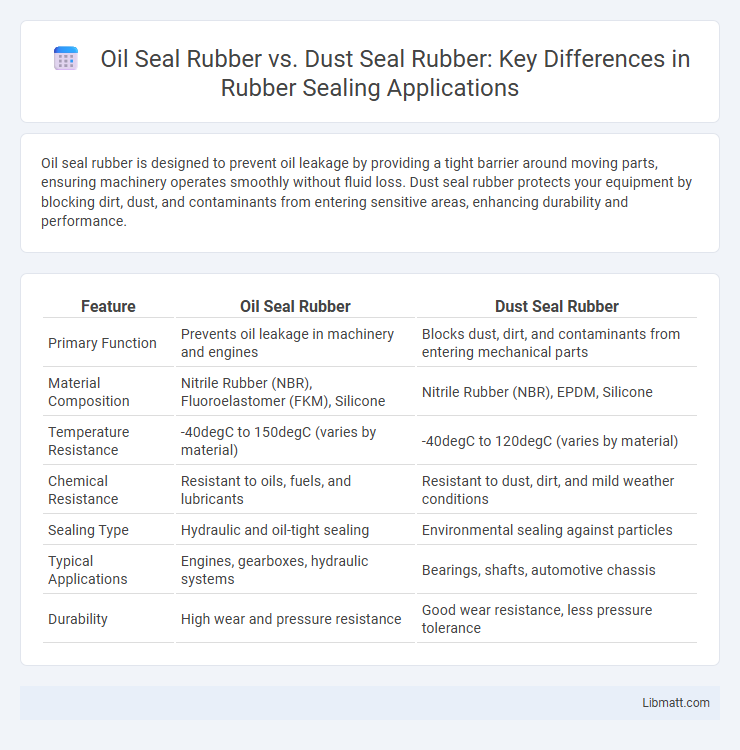

Oil seal rubber is designed to prevent oil leakage by providing a tight barrier around moving parts, ensuring machinery operates smoothly without fluid loss. Dust seal rubber protects your equipment by blocking dirt, dust, and contaminants from entering sensitive areas, enhancing durability and performance.

Table of Comparison

| Feature | Oil Seal Rubber | Dust Seal Rubber |

|---|---|---|

| Primary Function | Prevents oil leakage in machinery and engines | Blocks dust, dirt, and contaminants from entering mechanical parts |

| Material Composition | Nitrile Rubber (NBR), Fluoroelastomer (FKM), Silicone | Nitrile Rubber (NBR), EPDM, Silicone |

| Temperature Resistance | -40degC to 150degC (varies by material) | -40degC to 120degC (varies by material) |

| Chemical Resistance | Resistant to oils, fuels, and lubricants | Resistant to dust, dirt, and mild weather conditions |

| Sealing Type | Hydraulic and oil-tight sealing | Environmental sealing against particles |

| Typical Applications | Engines, gearboxes, hydraulic systems | Bearings, shafts, automotive chassis |

| Durability | High wear and pressure resistance | Good wear resistance, less pressure tolerance |

Introduction to Oil Seal Rubber and Dust Seal Rubber

Oil seal rubber is a specialized elastomer designed to prevent lubricant leakage in machinery by providing a tight barrier around rotating shafts, maintaining oil retention and contamination exclusion under high pressure and temperature conditions. Dust seal rubber, on the other hand, primarily blocks dust, dirt, and other airborne contaminants from entering mechanical components, enhancing the longevity of equipment without necessarily containing fluids. Both materials are engineered for durability and resistance, but oil seal rubbers emphasize fluid containment properties while dust seal rubbers focus on particulate exclusion and surface protection.

Key Functions of Oil Seal Rubber

Oil seal rubber primarily functions to prevent lubricants from leaking out of machinery while keeping contaminants like dirt and moisture from entering critical components. Its design ensures a tight seal around rotating shafts, maintaining the integrity of oil within engines and hydraulic systems. You rely on oil seal rubber to protect mechanical parts, reduce wear, and enhance overall equipment efficiency.

Primary Applications of Dust Seal Rubber

Dust seal rubber is primarily used in automotive and industrial machinery to prevent dirt, dust, and other contaminants from entering critical components such as wheel hubs, bearings, and gearboxes. Its flexible and durable composition ensures protection against abrasive particles while maintaining effective sealing under dynamic conditions. This seal type enhances equipment longevity and performance by minimizing wear and corrosion in harsh environments.

Material Composition: Oil Seal vs Dust Seal

Oil seal rubber is typically made from nitrile (NBR), fluoroelastomer (FKM), or silicone compounds designed to resist oil, heat, and chemicals, providing superior sealing in lubricated environments. Dust seal rubber usually consists of tougher, abrasion-resistant materials like polyurethane or EPDM, optimized for protecting against particulate contaminants rather than fluid leakage. Your selection should consider the operational environment, prioritizing oil compatibility for oil seals and particulate resistance for dust seals to ensure optimal performance and durability.

Performance in Harsh Environments

Oil seal rubber offers superior resistance to oil, chemicals, and extreme temperatures, making it ideal for sealing rotating shafts in harsh environments with exposure to lubricants and contaminants. Dust seal rubber, while effective in preventing dust and debris ingress, generally lacks the chemical and thermal resilience required for prolonged exposure to aggressive substances. In environments involving oil, heat, and abrasive particles, oil seal rubber maintains integrity and sealing performance more reliably than dust seal rubber.

Durability and Lifespan Comparison

Oil seal rubber typically offers superior durability and lifespan compared to dust seal rubber due to its ability to withstand constant exposure to lubricants, high temperatures, and pressure conditions. Dust seal rubber primarily prevents dirt and debris ingress and is less resistant to chemical degradation, resulting in a shorter service life in harsh environments. Choosing oil seal rubber for applications involving oil exposure enhances your equipment's longevity and maintenance intervals.

Common Industries for Each Seal Type

Oil seal rubber is predominantly used in the automotive, manufacturing, and heavy machinery industries where it prevents oil leakage and contamination in engines and hydraulic systems. Dust seal rubber finds common application in agriculture, construction equipment, and industrial machinery to protect components from dust, dirt, and debris intrusion. You can enhance equipment longevity by selecting the appropriate seal based on the specific environmental and operational requirements.

Maintenance Requirements: Oil Seal vs Dust Seal

Oil seal rubber demands more frequent maintenance due to its critical role in preventing lubricant leakage and protecting machinery from contaminants, which requires regular inspection and replacement in high-pressure environments. Dust seal rubber, typically used to block dirt and dust without retaining fluids, involves lower maintenance since it experiences less wear and retains flexibility over longer periods. Understanding these differences ensures your equipment benefits from optimal sealing performance and reduced downtime.

Cost Factors and Economic Considerations

Oil seal rubber generally costs more than dust seal rubber due to its specialized materials and enhanced design for preventing oil leakage under high pressure. Dust seal rubber, being simpler and less resistant to fluids and extreme conditions, offers a more economical choice for applications where contamination prevention is sufficient without the need for sealing oil. Your selection should weigh the cost difference against the operational requirements, as investing in oil seal rubber can reduce long-term maintenance and downtime costs despite the higher initial expense.

Choosing the Right Seal for Your Application

Oil seal rubber is specifically designed to prevent the leakage of lubricants in machinery, offering excellent resistance to oil, heat, and wear, making it ideal for automotive engines and gearboxes. Dust seal rubber, on the other hand, primarily blocks dirt, dust, and debris from entering sensitive components, ensuring contaminants do not compromise performance, commonly used in agricultural equipment and industrial machinery. Selecting the right seal depends on the operating environment: choose oil seal rubber for fluid containment and high-temperature resistance, while dust seal rubber is best for protecting against particulate ingress in dry conditions.

Oil seal rubber vs Dust seal rubber Infographic

libmatt.com

libmatt.com