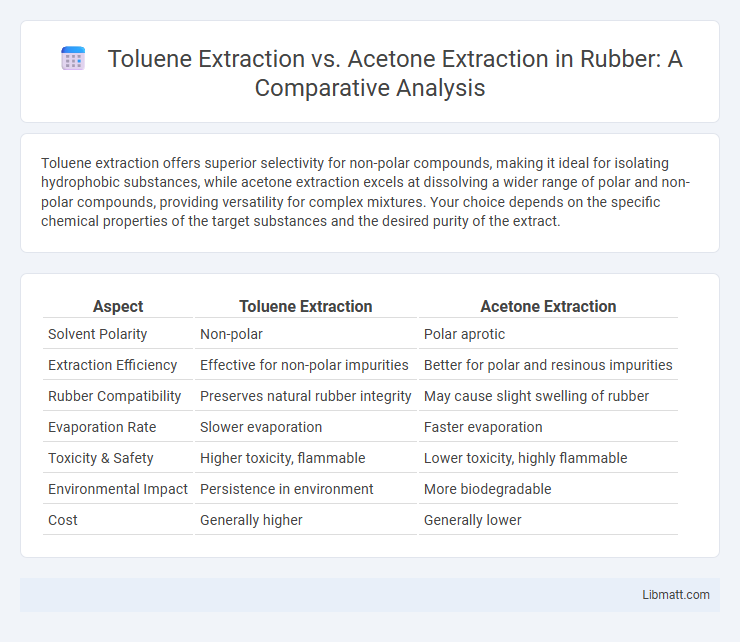

Toluene extraction offers superior selectivity for non-polar compounds, making it ideal for isolating hydrophobic substances, while acetone extraction excels at dissolving a wider range of polar and non-polar compounds, providing versatility for complex mixtures. Your choice depends on the specific chemical properties of the target substances and the desired purity of the extract.

Table of Comparison

| Aspect | Toluene Extraction | Acetone Extraction |

|---|---|---|

| Solvent Polarity | Non-polar | Polar aprotic |

| Extraction Efficiency | Effective for non-polar impurities | Better for polar and resinous impurities |

| Rubber Compatibility | Preserves natural rubber integrity | May cause slight swelling of rubber |

| Evaporation Rate | Slower evaporation | Faster evaporation |

| Toxicity & Safety | Higher toxicity, flammable | Lower toxicity, highly flammable |

| Environmental Impact | Persistence in environment | More biodegradable |

| Cost | Generally higher | Generally lower |

Overview of Toluene and Acetone Extraction

Toluene extraction relies on the solvent's ability to dissolve non-polar compounds, making it effective for extracting hydrophobic substances like oils and resins. Acetone extraction, by contrast, targets polar compounds due to acetone's polar nature, excelling in isolating substances such as fats, waxes, and certain organic compounds. Your choice between toluene and acetone extraction depends on the chemical properties of the target materials and desired purity levels.

Chemical Properties of Toluene and Acetone

Toluene, a non-polar aromatic hydrocarbon with low polarity and a boiling point of 110.6degC, excels in dissolving non-polar substances, making it ideal for extracting hydrophobic compounds. Acetone, a polar aprotic solvent with a boiling point of 56degC and a strong ability to dissolve both polar and non-polar substances, offers faster evaporation and effective extraction of a broader range of compounds. Your choice between toluene extraction and acetone extraction should consider these chemical properties to optimize solubility and separation efficiency.

Mechanisms of Solvent Extraction

Toluene extraction utilizes non-polar solvent mechanisms to dissolve hydrophobic compounds, making it highly effective for separating aromatic hydrocarbons from mixtures. Acetone extraction relies on polar solvent properties to dissolve a wide range of polar and semi-polar substances through hydrogen bonding and dipolar interactions. The difference in solvent polarity between toluene and acetone dictates their selective solubility and efficiency in extracting target compounds based on molecular affinity during the solvent extraction process.

Efficiency Comparison: Toluene vs Acetone

Toluene extraction exhibits higher selectivity for non-polar compounds, resulting in greater efficiency when isolating hydrophobic substances compared to acetone. Acetone's polarity allows it to dissolve a broader range of polar and semi-polar compounds but often leads to lower specificity and potential co-extraction of impurities. Efficiency in extraction processes depends on target compound polarity, with toluene providing superior yields for non-polar analytes and acetone favored for diverse, polar mixture extractions.

Selectivity in Compound Extraction

Toluene extraction offers higher selectivity for non-polar compounds due to its low polarity, making it ideal for isolating hydrophobic substances like aromatic hydrocarbons and essential oils. Acetone extraction, being a polar solvent, excels at dissolving a broader range of polar and semi-polar compounds, including phenolics and flavonoids. You should choose the solvent based on the polarity of the target compounds to maximize extraction efficiency and purity.

Safety and Health Considerations

Toluene extraction poses significant health risks due to its high toxicity and potential for causing neurological damage, requiring strict ventilation and protective gear to mitigate inhalation hazards. Acetone extraction, while still flammable and requiring careful handling, presents lower toxicity levels and faster evaporation rates that reduce prolonged exposure risks. Both solvents demand rigorous safety protocols, but acetone's comparatively safer profile makes it preferable in environments prioritizing worker health.

Environmental Impact and Sustainability

Toluene extraction generates higher environmental concerns due to its toxicity and persistence in ecosystems, leading to significant air and water pollution risks, while acetone extraction exhibits a lower environmental footprint with faster biodegradability and reduced toxicity. Acetone, being a volatile organic compound with rapid evaporation and minimal bioaccumulation, supports more sustainable industrial practices compared to toluene's harmful emissions and longer atmospheric lifetime. Adoption of acetone extraction aligns better with green chemistry principles by minimizing hazardous waste and facilitating safer disposal, promoting overall sustainability in chemical processing.

Applications in Industry and Research

Toluene extraction is widely used in industries such as paint manufacturing, adhesives, and pharmaceuticals for isolating non-polar compounds, while acetone extraction excels in research settings due to its strong solvency for polar and semi-polar substances, including plant metabolites. Your choice between toluene and acetone depends on specific application requirements, where toluene offers greater efficiency in extracting hydrophobic chemicals and acetone provides versatility for bioactive compound isolation. Both solvents play crucial roles in chemical synthesis, material processing, and analytical chemistry, shaping advancements in industrial production and scientific investigations.

Cost Analysis of Toluene and Acetone Extraction

Toluene extraction generally incurs higher costs due to its increased toxicity and the need for extensive safety measures, including specialized ventilation and protective equipment. Acetone extraction offers a more cost-effective alternative, with lower material expenses and simpler handling requirements, reducing overall operational expenditure. Your choice between toluene and acetone extraction hinges on balancing the initial investment with long-term safety and processing efficiencies.

Choosing the Right Solvent: Key Factors

Choosing the right solvent for extraction depends on factors such as polarity, solubility, and safety profile. Toluene, a non-polar solvent, excels in dissolving hydrophobic compounds but poses higher health risks due to its toxicity and volatility. Acetone, a polar solvent, offers a safer alternative with broad solubility for polar and non-polar substances, making it suitable for diverse extraction applications where safety and efficiency are priorities.

Toluene Extraction vs Acetone Extraction Infographic

libmatt.com

libmatt.com