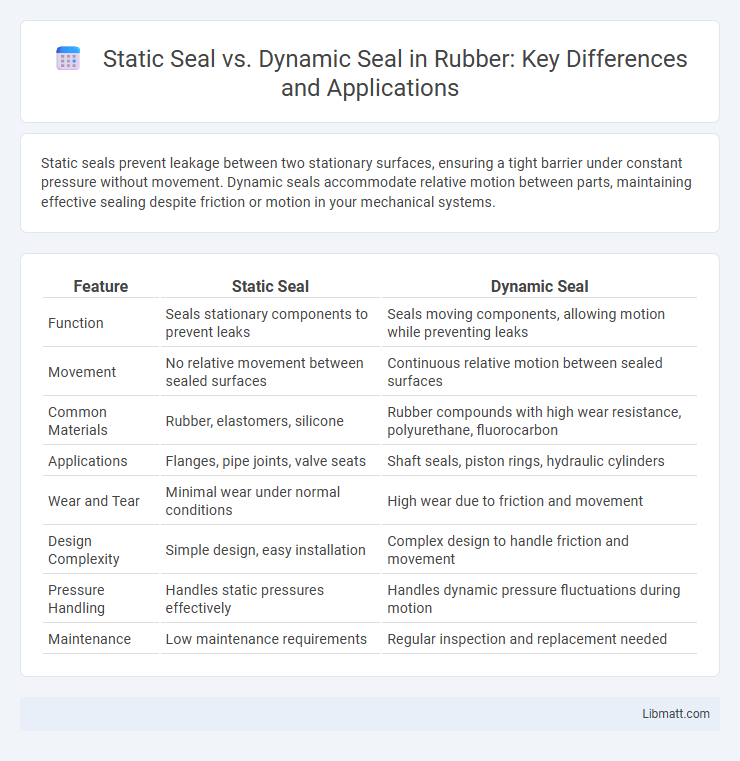

Static seals prevent leakage between two stationary surfaces, ensuring a tight barrier under constant pressure without movement. Dynamic seals accommodate relative motion between parts, maintaining effective sealing despite friction or motion in your mechanical systems.

Table of Comparison

| Feature | Static Seal | Dynamic Seal |

|---|---|---|

| Function | Seals stationary components to prevent leaks | Seals moving components, allowing motion while preventing leaks |

| Movement | No relative movement between sealed surfaces | Continuous relative motion between sealed surfaces |

| Common Materials | Rubber, elastomers, silicone | Rubber compounds with high wear resistance, polyurethane, fluorocarbon |

| Applications | Flanges, pipe joints, valve seats | Shaft seals, piston rings, hydraulic cylinders |

| Wear and Tear | Minimal wear under normal conditions | High wear due to friction and movement |

| Design Complexity | Simple design, easy installation | Complex design to handle friction and movement |

| Pressure Handling | Handles static pressures effectively | Handles dynamic pressure fluctuations during motion |

| Maintenance | Low maintenance requirements | Regular inspection and replacement needed |

Introduction to Sealing Technologies

Static seals maintain leakage prevention by creating a tight interface between two stationary surfaces, commonly used in gaskets and O-rings for flanges and pipe joints. Dynamic seals accommodate relative motion between components, such as rotary shafts or reciprocating pistons, using advanced materials like PTFE or elastomers to ensure durability and flexibility under varying pressure and temperature conditions. Innovations in sealing technologies enhance performance by improving chemical resistance, reducing friction, and extending service life in industrial applications like automotive, aerospace, and manufacturing.

Defining Static Seals

Static seals prevent fluid leakage between stationary components by creating a tight barrier under constant pressure and no relative motion. Common types include O-rings, gaskets, and flange seals, designed to withstand high pressure and temperature conditions. Understanding the properties of static seals helps you select the right seal for applications requiring leakage prevention without movement.

Understanding Dynamic Seals

Dynamic seals are specifically designed to maintain sealing integrity in applications with relative motion between sealing surfaces, such as rotating shafts or reciprocating pistons. Unlike static seals, which remain stationary and prevent fluid leakage at fixed interfaces, dynamic seals must accommodate continuous movement while preventing leaks under varying pressure and temperature conditions. Key examples include O-rings, lip seals, and mechanical seals, which combine elasticity and wear resistance to enhance performance in dynamic environments.

Key Differences Between Static and Dynamic Seals

Static seals prevent leakage between two stationary surfaces by maintaining a tight barrier, while dynamic seals accommodate relative motion between surfaces, such as rotation or reciprocation, without losing integrity. Key differences include design complexity, with dynamic seals requiring more durable materials to withstand friction and wear, and application-specific performance, as static seals are used in fixed joints and dynamic seals in moving parts like shafts or pistons. Your selection depends on whether components remain stationary or move relative to each other, impacting seal efficiency and lifespan.

Common Materials Used for Static and Dynamic Seals

Common materials used for static seals include elastomers such as nitrile rubber (NBR), silicone, and fluorocarbon (Viton) due to their excellent compression set resistance and chemical stability. Dynamic seals often employ materials with enhanced wear resistance and flexibility, like polyurethane, PTFE (polytetrafluoroethylene), and advanced elastomers designed to withstand friction and continuous movement. Selecting the appropriate material depends on factors like operating temperature, pressure, fluid compatibility, and the specific dynamic or static application requirements.

Applications of Static Seals

Static seals are primarily used in applications where two or more stationary components are joined to prevent fluid or gas leakage, such as in flange gaskets, O-rings in pipe joints, and sealing surfaces of pumps and compressors. They are ideal for high-pressure environments in industries like oil and gas, chemical processing, and automotive manufacturing due to their reliability in maintaining a tight seal without movement. Static seals offer durability and chemical resistance, making them essential for static interfaces exposed to corrosive fluids and extreme temperatures.

Applications of Dynamic Seals

Dynamic seals are primarily used in applications involving moving parts such as rotating shafts, reciprocating pistons, and hydraulic cylinders to prevent fluid leakage under varying pressure and temperature conditions. Common industries utilizing dynamic seals include automotive, aerospace, and manufacturing, where they ensure reliable performance in pumps, engines, gearboxes, and hydraulic systems. Advanced materials like PTFE, rubber composites, and elastomers enhance durability and resistance to wear, friction, and chemical exposure in demanding environments.

Performance Factors: Static Seal vs Dynamic Seal

Static seals provide superior performance in applications with minimal or no movement, ensuring effective prevention of leaks under constant pressure and temperature conditions. Dynamic seals are designed to accommodate relative motion between surfaces, maintaining performance through flexibility and wear resistance in rotating or reciprocating equipment. Your choice between static and dynamic seals should consider factors like pressure variability, motion speed, and environmental conditions to optimize sealing efficiency and longevity.

Selection Criteria for Seal Types

Selection criteria for static seals versus dynamic seals primarily depend on the type of movement and pressure conditions in your system. Static seals are ideal for applications involving no relative motion between sealing surfaces, providing effective leakage prevention under high pressure and temperature variations. Dynamic seals are necessary for components with relative motion, such as rotating shafts or pistons, where flexibility, durability, and low friction are critical to maintaining system integrity.

Conclusion: Choosing the Right Seal for Your Application

Selecting the right seal depends on the type of motion involved and operating conditions; static seals are ideal for sealing between stationary surfaces, providing reliable leak prevention under high pressure without wear concerns. Dynamic seals accommodate movement between parts, such as rotating shafts or pistons, and must withstand friction and wear while maintaining sealing integrity. Evaluating factors like pressure, speed, temperature, and fluid compatibility guides the choice between static and dynamic seals for optimal performance and longevity.

Static Seal vs Dynamic Seal Infographic

libmatt.com

libmatt.com