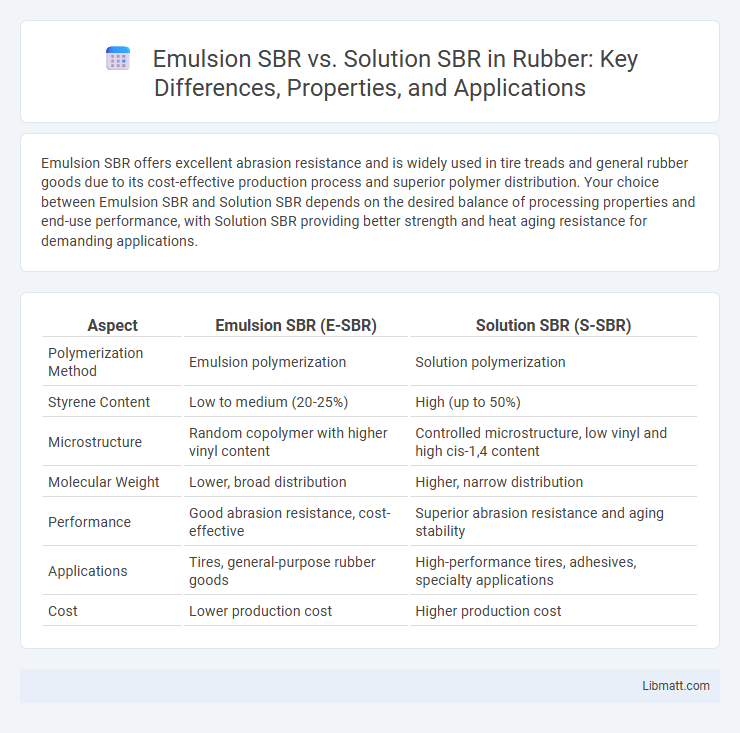

Emulsion SBR offers excellent abrasion resistance and is widely used in tire treads and general rubber goods due to its cost-effective production process and superior polymer distribution. Your choice between Emulsion SBR and Solution SBR depends on the desired balance of processing properties and end-use performance, with Solution SBR providing better strength and heat aging resistance for demanding applications.

Table of Comparison

| Aspect | Emulsion SBR (E-SBR) | Solution SBR (S-SBR) |

|---|---|---|

| Polymerization Method | Emulsion polymerization | Solution polymerization |

| Styrene Content | Low to medium (20-25%) | High (up to 50%) |

| Microstructure | Random copolymer with higher vinyl content | Controlled microstructure, low vinyl and high cis-1,4 content |

| Molecular Weight | Lower, broad distribution | Higher, narrow distribution |

| Performance | Good abrasion resistance, cost-effective | Superior abrasion resistance and aging stability |

| Applications | Tires, general-purpose rubber goods | High-performance tires, adhesives, specialty applications |

| Cost | Lower production cost | Higher production cost |

Introduction to SBR: Emulsion vs. Solution Processes

Styrene-Butadiene Rubber (SBR) is synthesized through two primary processes: emulsion and solution polymerization, each offering distinct properties and applications. Emulsion SBR is produced via free radical polymerization in an aqueous medium, resulting in a polymer with high cis-1,4 content and enhanced abrasion resistance ideal for tire treads and general rubber goods. Solution SBR employs coordination catalysts in an organic solvent, yielding a polymer with better control over microstructure, higher styrene content, and improved resilience, commonly used in high-performance tires and mechanical goods.

Chemical Structure Differences: Emulsion SBR vs. Solution SBR

Emulsion SBR features a copolymer with a higher content of styrene and butadiene units arranged in a random, branched structure, resulting from its radical polymerization process in aqueous media. Solution SBR, produced via anionic polymerization in organic solvents, exhibits a more uniform molecular weight distribution with a linear chain structure and higher cis-1,4 content, enhancing its crystallinity and mechanical properties. Your choice between Emulsion SBR and Solution SBR depends on the desired balance of abrasion resistance and processability derived from these chemical structure differences.

Manufacturing Process Overview

Emulsion SBR (Styrene-Butadiene Rubber) is produced through a radical polymerization process in an aqueous emulsion, resulting in latex particles dispersed in water, while Solution SBR is synthesized via anionic polymerization in an organic solvent, yielding a more uniform polymer chain distribution. Emulsion SBR manufacturing involves complex surfactant systems and mechanical stirring to maintain the emulsion's stability, whereas Solution SBR requires stringent temperature and moisture control to preserve the solvent environment and polymer properties. The different polymerization techniques directly influence the molecular weight distribution, microstructure, and application performance of the final synthetic rubber products.

Performance Characteristics Comparison

Emulsion SBR (E-SBR) offers superior abrasion resistance and better wet traction, making it ideal for tire treads requiring durability and safety in wet conditions. Solution SBR (S-SBR) provides enhanced processability and improved rolling resistance, contributing to better fuel efficiency and easier manufacturing in automotive applications. The choice between E-SBR and S-SBR depends on balancing cost-effectiveness with performance demands such as wear resistance and fuel economy.

Applications and Industry Uses

Emulsion SBR (Styrene-Butadiene Rubber) is widely used in tire manufacturing, footwear, adhesives, and carpets due to its excellent abrasion resistance and cost-effectiveness. Solution SBR offers superior strength and heat resistance, making it ideal for high-performance tires, industrial belts, and specialty rubber goods requiring enhanced durability. Your choice between Emulsion SBR and Solution SBR depends on the specific application needs within automotive, construction, and consumer product industries.

Environmental Impact and Sustainability

Emulsion SBR (Styrene-Butadiene Rubber) production generally has a lower environmental impact compared to Solution SBR due to its water-based polymerization process, which reduces the use of organic solvents and volatile organic compound (VOC) emissions. Emulsion SBR is considered more sustainable since it requires less energy and generates fewer hazardous waste byproducts, making it a preferred choice in eco-friendly tire manufacturing. In contrast, Solution SBR involves solvent-based polymerization, resulting in higher VOC emissions and greater environmental concerns related to solvent recovery and disposal.

Cost Analysis: Emulsion vs. Solution SBR

Emulsion Styrene-Butadiene Rubber (E-SBR) typically incurs lower production costs compared to Solution Styrene-Butadiene Rubber (S-SBR) due to its water-based polymerization process, which requires less energy and simpler equipment. S-SBR offers superior polymer microstructure control and performance attributes but demands higher capital investment and raw material costs, leading to increased overall expenses. Cost efficiency in E-SBR makes it favorable for large-scale, cost-sensitive applications, whereas S-SBR justifies its premium pricing in high-performance tire and specialty rubber markets.

Processing and Handling Differences

Emulsion SBR (Styrene-Butadiene Rubber) is typically processed as a latex, requiring coagulation to obtain solid rubber, which involves slower drying times and more complex handling equipment compared to Solution SBR that is produced in a soluble form, facilitating easier blending with other elastomers and fillers. Solution SBR offers superior processability with fewer impurities, enabling smoother compounding and better compatibility with manufacturing processes such as extrusion and molding. In industrial applications, Solution SBR's lower viscosity and higher purity reduce processing costs and improve final product consistency, while Emulsion SBR demands more rigorous control of moisture and residual surfactants during handling.

Recent Advancements in SBR Technology

Recent advancements in Styrene-Butadiene Rubber (SBR) technology have significantly improved both Emulsion SBR and Solution SBR properties, enhancing their performance in tire manufacturing and industrial applications. Emulsion SBR now benefits from improved polymerization techniques that increase molecular weight and control branching, resulting in better abrasion resistance and wet traction. Solution SBR innovations focus on precise microstructure control and higher styrene content, offering superior tensile strength and rolling resistance, allowing your products to achieve enhanced durability and fuel efficiency.

Choosing the Right SBR for Your Application

Emulsion SBR offers superior abrasion resistance and cost-effectiveness, making it ideal for applications like tire treads and footwear where durability is crucial. Solution SBR provides better control over polymer structure and higher purity, which enhances performance in adhesives, sealants, and high-quality rubber products. Choosing the right SBR depends on prioritizing factors like mechanical properties, manufacturing process, and end-use requirements to optimize product performance.

Emulsion SBR vs Solution SBR Infographic

libmatt.com

libmatt.com