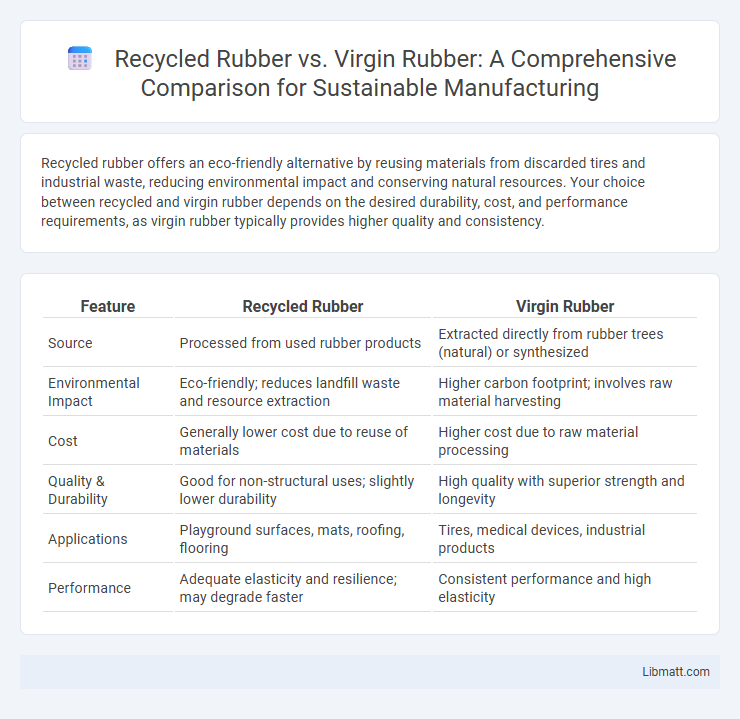

Recycled rubber offers an eco-friendly alternative by reusing materials from discarded tires and industrial waste, reducing environmental impact and conserving natural resources. Your choice between recycled and virgin rubber depends on the desired durability, cost, and performance requirements, as virgin rubber typically provides higher quality and consistency.

Table of Comparison

| Feature | Recycled Rubber | Virgin Rubber |

|---|---|---|

| Source | Processed from used rubber products | Extracted directly from rubber trees (natural) or synthesized |

| Environmental Impact | Eco-friendly; reduces landfill waste and resource extraction | Higher carbon footprint; involves raw material harvesting |

| Cost | Generally lower cost due to reuse of materials | Higher cost due to raw material processing |

| Quality & Durability | Good for non-structural uses; slightly lower durability | High quality with superior strength and longevity |

| Applications | Playground surfaces, mats, roofing, flooring | Tires, medical devices, industrial products |

| Performance | Adequate elasticity and resilience; may degrade faster | Consistent performance and high elasticity |

Introduction to Rubber Materials

Recycled rubber is produced by processing used rubber products, offering an environmentally friendly alternative to virgin rubber, which is made from fresh raw materials extracted from rubber trees. Your choice between recycled and virgin rubber impacts durability, cost, and environmental footprint, as recycled rubber often contains a mix of compounds with slightly altered physical properties. Understanding the source and processing of these rubber materials helps in selecting the right type for applications such as tires, flooring, and industrial products.

What is Recycled Rubber?

Recycled rubber is produced by processing used rubber products, such as tires and industrial scraps, through grinding and refining methods to create new, eco-friendly materials. This sustainable alternative retains many of the elastic and durable properties of virgin rubber while significantly reducing landfill waste and environmental impact. Industries utilize recycled rubber in applications ranging from playground surfaces to athletic tracks, promoting circular economy practices.

What is Virgin Rubber?

Virgin rubber refers to natural or synthetic rubber that is produced directly from raw materials without any prior processing or reuse. It offers consistent quality, enhanced elasticity, and superior durability compared to recycled rubber, making it ideal for applications requiring high performance and reliability. Manufacturers prefer virgin rubber for products such as tires, seals, and medical devices where purity and material integrity are critical.

Manufacturing Processes Compared

Recycled rubber manufacturing involves collecting used rubber products, cleaning, shredding, and devulcanizing them to restore flexibility for reuse in new products, significantly reducing raw material consumption and energy usage. Virgin rubber production starts from natural latex extraction or synthetic polymerization, followed by compounding and vulcanization to create high-quality, consistent materials with precise performance characteristics. Comparing both, recycled rubber offers environmental benefits with lower carbon footprints, while virgin rubber ensures superior mechanical properties essential for demanding industrial applications.

Environmental Impact: Recycled vs Virgin

Recycled rubber significantly reduces environmental impact by lowering landfill waste and decreasing the need for new raw material extraction, conserving natural resources. Virgin rubber production involves energy-intensive processes and deforestation, contributing to higher carbon emissions and habitat destruction. Your choice of recycled rubber supports sustainable practices and helps minimize the ecological footprint associated with rubber manufacturing.

Performance and Durability Differences

Recycled rubber typically exhibits lower tensile strength and elasticity compared to virgin rubber, affecting performance in high-stress applications. Virgin rubber maintains superior durability, resisting wear, tear, and environmental factors such as UV exposure and temperature fluctuations more effectively. Your choice between recycled and virgin rubber should consider these differences in performance and longevity for optimal application results.

Cost Comparison and Economic Benefits

Recycled rubber typically costs 30-50% less than virgin rubber, making it a more budget-friendly option for manufacturers seeking to reduce material expenses. The use of recycled rubber supports circular economy practices by lowering waste management costs and decreasing reliance on crude oil derivatives, which fluctuate in price. Economic benefits include reduced environmental remediation expenses and eligibility for tax incentives or grants targeting sustainable materials adoption.

Applications in Industry and Everyday Products

Recycled rubber finds extensive use in industrial applications such as playground surfaces, athletic tracks, and automotive mats due to its cost-effectiveness and sustainability benefits. Virgin rubber remains preferred in high-performance sectors like automotive tires, medical devices, and heavy-duty seals for its superior durability and elasticity. Both materials are crucial in everyday products, with recycled rubber increasingly incorporated into flooring and footwear, while virgin rubber dominates in products requiring high strength and resilience.

Quality Standards and Certifications

Recycled rubber meets industry quality standards such as ASTM D412 for tensile strength and ISO 14001 environmental management certification, ensuring sustainable production without compromising durability. Virgin rubber often exceeds these benchmarks, offering superior purity and consistent performance crucial for high-precision applications in automotive and medical industries. Your choice between recycled and virgin rubber should consider specific certification requirements to guarantee product integrity and regulatory compliance.

Future Trends in Rubber Sustainability

Future trends in rubber sustainability emphasize the growing adoption of recycled rubber due to its lower environmental impact compared to virgin rubber, reducing landfill waste and reliance on natural resources. Innovations in recycling technologies and eco-friendly processing methods are enhancing the performance and durability of recycled rubber, making it a viable alternative for various industrial applications. Your choice to prioritize recycled rubber supports circular economy initiatives and aligns with increasing regulatory pressures for sustainable material sourcing in the rubber industry.

Recycled Rubber vs Virgin Rubber Infographic

libmatt.com

libmatt.com