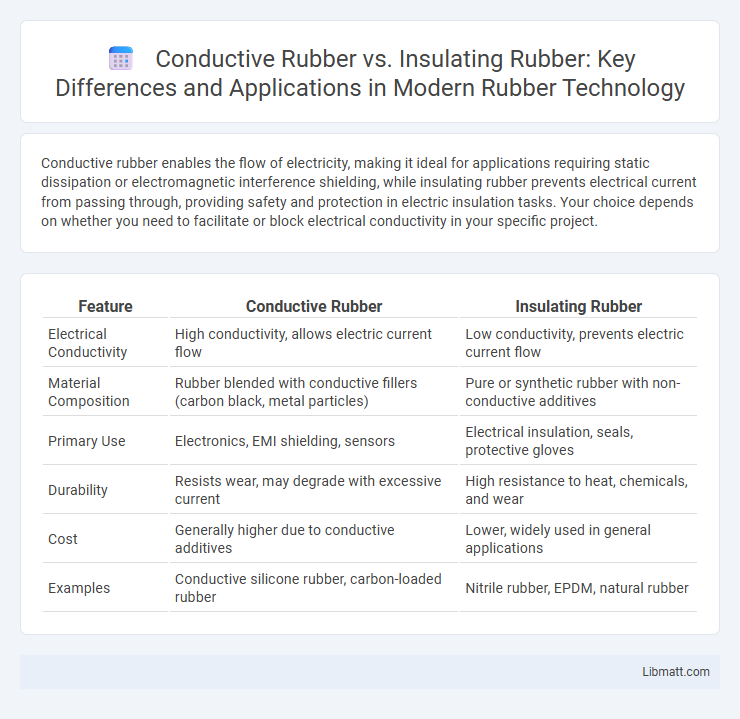

Conductive rubber enables the flow of electricity, making it ideal for applications requiring static dissipation or electromagnetic interference shielding, while insulating rubber prevents electrical current from passing through, providing safety and protection in electric insulation tasks. Your choice depends on whether you need to facilitate or block electrical conductivity in your specific project.

Table of Comparison

| Feature | Conductive Rubber | Insulating Rubber |

|---|---|---|

| Electrical Conductivity | High conductivity, allows electric current flow | Low conductivity, prevents electric current flow |

| Material Composition | Rubber blended with conductive fillers (carbon black, metal particles) | Pure or synthetic rubber with non-conductive additives |

| Primary Use | Electronics, EMI shielding, sensors | Electrical insulation, seals, protective gloves |

| Durability | Resists wear, may degrade with excessive current | High resistance to heat, chemicals, and wear |

| Cost | Generally higher due to conductive additives | Lower, widely used in general applications |

| Examples | Conductive silicone rubber, carbon-loaded rubber | Nitrile rubber, EPDM, natural rubber |

Introduction to Conductive and Insulating Rubber

Conductive rubber contains carbon or metal fillers that enable electrical conductivity, making it ideal for applications requiring static dissipation or electromagnetic interference shielding. Insulating rubber, composed of non-conductive polymers, prevents current flow and provides excellent electrical insulation in cables, seals, and protective gear. Understanding the fundamental properties of your conductive or insulating rubber helps optimize performance in electronic and industrial uses.

Key Definitions and Material Composition

Conductive rubber contains conductive fillers such as carbon black or metallic particles, enabling it to transmit electricity, whereas insulating rubber is composed of non-conductive polymers like silicone or silicone blends that prevent electrical flow. The material composition of conductive rubber typically integrates elastomers with conductive additives to achieve desired conductivity levels, while insulating rubber relies on polymers with high dielectric strength to resist electrical currents. Understanding these key definitions and material differences helps you select the appropriate rubber type for applications requiring either electrical conductivity or insulation.

Electrical Properties: Conductivity vs. Insulation

Conductive rubber exhibits low electrical resistance due to the inclusion of conductive fillers like carbon black or metal particles, enabling efficient electron flow for applications requiring electrical grounding or signal transmission. In contrast, insulating rubber possesses high resistivity, preventing electrical current flow and providing effective protection against electrical shocks and short circuits in devices. The choice between conductive and insulating rubber depends on specific electrical property requirements such as conductivity levels, dielectric strength, and application voltage.

Common Applications of Conductive Rubber

Conductive rubber is widely used in electronic devices for EMI shielding, flexible circuits, and tactile keypad contacts due to its excellent electrical conductivity combined with flexibility. It is essential in applications requiring static discharge prevention, such as in antistatic mats and gloves, where it safeguards sensitive components from electrostatic damage. Your choice of conductive rubber can optimize performance in sensors, flexible connectors, and grounding systems where reliable electrical contact is crucial.

Typical Uses for Insulating Rubber

Insulating rubber is widely used in electrical applications to prevent the flow of electric current, making it essential for protective gloves, mats, and cable insulation to ensure user safety. Its high dielectric strength and resistance to heat and chemicals make it ideal for safeguarding electrical workers and maintaining system integrity. Your equipment and personnel benefit from reliable insulation, reducing the risk of electrical shock and equipment failure.

Manufacturing Processes and Formulation Differences

Conductive rubber is manufactured by incorporating conductive fillers such as carbon black, metal powders, or graphene into the polymer matrix, enhancing its electrical conductivity through percolation networks. In contrast, insulating rubber focuses on formulations that utilize non-conductive fillers like silica or clay to maintain high electrical resistance and prevent current flow. The manufacturing process for conductive rubber often requires precise dispersion techniques and blending conditions to optimize the uniform distribution of conductive additives, while insulating rubber emphasizes purity and additive compatibility to achieve superior dielectric properties.

Mechanical and Physical Property Comparison

Conductive rubber exhibits enhanced electrical conductivity due to the inclusion of conductive fillers like carbon black or metal particles, while insulating rubber maintains high resistivity for electrical insulation. Mechanically, conductive rubber often shows increased stiffness and reduced elasticity compared to insulating rubber, which typically offers superior flexibility and elongation at break. Physically, conductive rubber may have higher hardness and lower compression set, affecting its durability and wear resistance in applications requiring electrical conductivity versus insulation.

Safety Considerations and Standards

Conductive rubber is engineered to allow the flow of electrical current, making it essential in applications requiring electrostatic discharge protection, while insulating rubber is designed to prevent current flow, ensuring electrical isolation and shock protection. Safety considerations for conductive rubber include compliance with standards such as ANSI/ESD S20.20 for electrostatic discharge control, whereas insulating rubber must meet ASTM D297 for dielectric strength and ASTM D1457 for insulation properties. Your choice between conductive and insulating rubber should prioritize adherence to relevant industry standards to maintain effective safety protocols in electrical environments.

Factors for Material Selection in Industrial Use

Material selection between conductive rubber and insulating rubber in industrial applications depends primarily on electrical conductivity requirements, environmental conditions, and mechanical durability. Conductive rubber is chosen for applications needing static dissipation or electromagnetic interference shielding, while insulating rubber excels in preventing electrical current flow and protecting components from electrical hazards. Your decision should also consider temperature resistance, chemical exposure, and flexibility to ensure optimal performance and safety.

Future Trends and Innovations in Rubber Technology

Future trends in rubber technology emphasize the development of conductive rubber with enhanced electrical properties through the incorporation of nanomaterials like graphene and carbon nanotubes, enabling applications in flexible electronics and wearable devices. Innovations in insulating rubber focus on improving thermal stability and dielectric strength by integrating advanced fillers such as silica and alumina, catering to high-voltage and automotive insulation needs. Both types are progressing toward sustainability by leveraging bio-based polymers and greener manufacturing processes to reduce environmental impact.

Conductive Rubber vs Insulating Rubber Infographic

libmatt.com

libmatt.com