EPDM roofing offers superior resistance to UV rays, ozone, and extreme weather conditions, making it ideal for long-lasting durability, while TPO roofing provides excellent energy efficiency through its reflective properties that reduce cooling costs. Choosing between EPDM and TPO depends on your priorities for weather resistance versus energy savings on your roofing system.

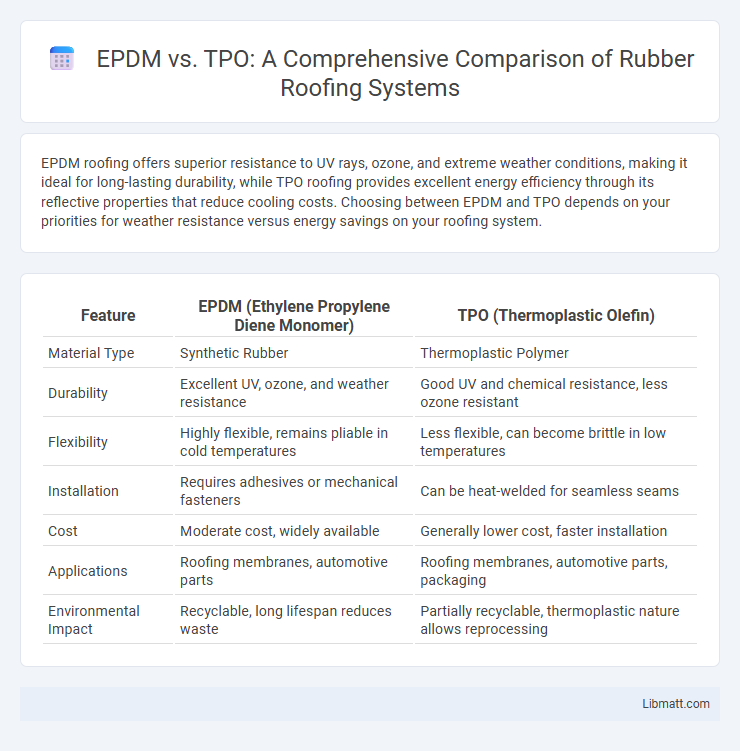

Table of Comparison

| Feature | EPDM (Ethylene Propylene Diene Monomer) | TPO (Thermoplastic Olefin) |

|---|---|---|

| Material Type | Synthetic Rubber | Thermoplastic Polymer |

| Durability | Excellent UV, ozone, and weather resistance | Good UV and chemical resistance, less ozone resistant |

| Flexibility | Highly flexible, remains pliable in cold temperatures | Less flexible, can become brittle in low temperatures |

| Installation | Requires adhesives or mechanical fasteners | Can be heat-welded for seamless seams |

| Cost | Moderate cost, widely available | Generally lower cost, faster installation |

| Applications | Roofing membranes, automotive parts | Roofing membranes, automotive parts, packaging |

| Environmental Impact | Recyclable, long lifespan reduces waste | Partially recyclable, thermoplastic nature allows reprocessing |

Introduction to EPDM and TPO Roofing

EPDM roofing is a durable synthetic rubber membrane known for its excellent resistance to UV rays, weathering, and thermal shock, making it ideal for flat or low-slope roofs. TPO roofing consists of a single-ply reflective membrane made from polypropylene and ethylene-propylene rubber, offering high energy efficiency through its heat-reflective properties. Both materials provide strong waterproofing solutions but differ in composition, flexibility, and environmental impact, influencing their suitability for various commercial roofing applications.

Key Material Differences: EPDM vs TPO

EPDM (ethylene propylene diene monomer) is a synthetic rubber known for its excellent resistance to UV rays, ozone, and extreme weather conditions, making it highly durable for roofing applications. TPO (thermoplastic olefin) is a single-ply membrane combining the durability of rubber and the heat-weldability of thermoplastics, offering superior puncture resistance and energy efficiency due to its reflective surface. Key material differences include EPDM's flexible, non-heat-weldable nature versus TPO's thermoplastic composition that allows heat welding, impacting installation methods and long-term performance.

Installation Process Comparison

EPDM roofing typically involves a straightforward single-ply membrane installation that can be mechanically fastened, fully adhered, or ballasted, offering versatility in various roof configurations. TPO roofing requires heat welding seams to create a strong, watertight bond, which demands specialized equipment and skilled labor for proper installation. The EPDM process generally allows for faster installation with fewer specialized tools compared to the TPO method, which necessitates precision to ensure seam integrity.

Energy Efficiency and Reflectivity

EPDM roofing is known for its durability but tends to absorb more heat due to its dark color, which can increase cooling costs. TPO roofing offers superior energy efficiency with high reflectivity, reflecting UV rays and reducing rooftop temperatures. This reflectivity helps lower overall building energy consumption, making TPO a popular choice for sustainable, energy-efficient roofing systems.

Durability and Weather Resistance

EPDM roofing exhibits exceptional durability against UV radiation, ozone, and extreme temperature fluctuations, maintaining flexibility in cold weather and resisting cracking. TPO roofing offers strong resistance to chemical exposure, punctures, and reflectivity, contributing to energy efficiency and prolonged lifespan in hot climates. Both materials provide excellent weather resistance, yet EPDM is typically favored in colder environments while TPO excels in high-heat applications.

Maintenance Requirements

EPDM roofing requires minimal maintenance, typically involving regular inspections and cleaning to remove debris and prevent moss growth. TPO roofing demands consistent monitoring for seams and punctures due to its heat-welded membranes, which can be prone to UV damage over time. Both materials benefit from timely repairs to extend their lifespan and maintain energy efficiency.

Cost Analysis: EPDM vs TPO

EPDM roofing typically offers a lower initial installation cost compared to TPO, making it a budget-friendly option for large-scale commercial projects. TPO, while generally more expensive upfront, provides greater energy efficiency through superior heat-reflective properties, potentially reducing long-term energy expenses. Cost analysis between EPDM and TPO must consider maintenance, durability, and climate factors, as EPDM's longer lifespan can offset its lower initial price.

Environmental Impact and Sustainability

EPDM roofing membranes are known for their long lifespan and resistance to UV radiation, which reduces the frequency of replacement and minimizes landfill waste, contributing positively to sustainability. TPO membranes offer high reflectivity and energy efficiency, leading to lower cooling costs and reduced greenhouse gas emissions over the roof's lifecycle. Both materials can be recycled, but the recycling infrastructure for EPDM is more established, enhancing its environmental impact benefits compared to TPO.

Common Applications and Best Use Cases

EPDM roofing excels in commercial and industrial buildings due to its outstanding resistance to UV rays, ozone, and extreme temperatures, making it ideal for flat or low-slope roofs in varying climates. TPO membranes are widely used in commercial roofing where energy efficiency and heat reflection are priorities, especially on new constructions or reroofing projects requiring robust puncture resistance and heat-welded seams. Your choice between EPDM and TPO should consider the specific environmental conditions and performance needs of the roofing project.

How to Choose Between EPDM and TPO

Selecting between EPDM and TPO roofing depends on factors such as climate, budget, and roof specifications. EPDM excels in extreme weather resistance and longevity, making it ideal for colder regions with frequent temperature fluctuations. Your choice should consider TPO's superior energy efficiency and ease of installation, especially beneficial for commercial buildings aiming to reduce cooling costs.

EPDM vs TPO Infographic

libmatt.com

libmatt.com