Reinforced rubber contains materials like fabric or metal to enhance strength, durability, and resistance to abrasion, making it ideal for heavy-duty applications. Unreinforced rubber offers greater flexibility and elasticity but lacks the structural support needed for high-stress environments, so your choice depends on the specific demands of your project.

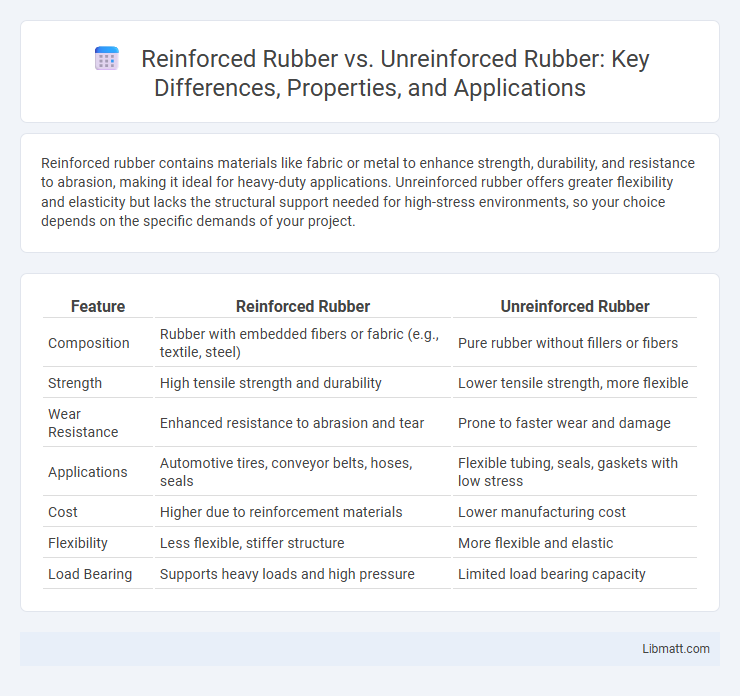

Table of Comparison

| Feature | Reinforced Rubber | Unreinforced Rubber |

|---|---|---|

| Composition | Rubber with embedded fibers or fabric (e.g., textile, steel) | Pure rubber without fillers or fibers |

| Strength | High tensile strength and durability | Lower tensile strength, more flexible |

| Wear Resistance | Enhanced resistance to abrasion and tear | Prone to faster wear and damage |

| Applications | Automotive tires, conveyor belts, hoses, seals | Flexible tubing, seals, gaskets with low stress |

| Cost | Higher due to reinforcement materials | Lower manufacturing cost |

| Flexibility | Less flexible, stiffer structure | More flexible and elastic |

| Load Bearing | Supports heavy loads and high pressure | Limited load bearing capacity |

Introduction to Reinforced and Unreinforced Rubber

Reinforced rubber incorporates materials such as fabric, steel, or synthetic fibers to enhance strength, durability, and resistance to wear, making it ideal for applications requiring increased mechanical performance. Unreinforced rubber consists solely of the base elastomer without additives, offering greater flexibility and elasticity but lower resistance to stress and deformation. Understanding the properties of both types is essential for selecting the right material in industries like automotive, industrial machinery, and consumer products.

Composition and Material Differences

Reinforced rubber contains added fibers, fabrics, or fillers such as carbon black, silica, or steel cords, which enhance tensile strength, durability, and resistance to wear compared to unreinforced rubber. Unreinforced rubber, typically composed of pure elastomers like natural rubber or synthetic polymers without fillers, offers greater flexibility and elasticity but lower mechanical strength. These material differences make reinforced rubber suitable for heavy-duty applications requiring structural support, while unreinforced rubber is preferred for flexible, lightweight uses.

Manufacturing Processes

Reinforced rubber undergoes a manufacturing process that incorporates fibers, fabrics, or other reinforcement materials such as steel or nylon during the curing stage, enhancing its strength, durability, and resistance to deformation. Unreinforced rubber is produced by mixing polymers with curing agents and additives without any reinforcement, resulting in a more flexible but less durable material. The reinforcement process involves precise alignment and bonding techniques to ensure optimal performance in applications requiring high tensile strength and impact resistance.

Mechanical Strength and Durability

Reinforced rubber exhibits significantly higher mechanical strength and durability compared to unreinforced rubber, thanks to the inclusion of fillers like carbon black or fabric layers that enhance its resistance to wear, tear, and fatigue. Your applications demanding superior load-bearing capacity and extended service life benefit from reinforced rubber's improved tensile strength, tear resistance, and resistance to environmental degradation. Unreinforced rubber, while more flexible, typically fails to provide the same level of robustness needed for heavy-duty or high-stress conditions.

Flexibility and Elasticity

Reinforced rubber exhibits enhanced tensile strength and durability due to embedded fibers or fabric, which slightly reduces its flexibility compared to unreinforced rubber. Unreinforced rubber offers superior elasticity and greater stretchability, making it ideal for applications requiring frequent deformation and recovery. The choice between reinforced and unreinforced rubber depends on balancing the need for mechanical strength against maximum flexibility and elastic performance.

Applications in Industry

Reinforced rubber is extensively used in automotive tires, conveyor belts, and hoses due to its enhanced durability and tensile strength, resisting wear and tear under mechanical stress. Unreinforced rubber finds applications in seals, gaskets, and flexible moldings where flexibility and elasticity without high load-bearing capacity are required. Industries prioritize reinforced variants in heavy-duty environments for prolonged performance, while unreinforced rubber suits less demanding applications needing superior elasticity and chemical resistance.

Cost Considerations

Reinforced rubber typically incurs higher costs due to the inclusion of materials such as fabric or steel fibers that enhance durability and strength. Unreinforced rubber is more budget-friendly but may require more frequent replacement or maintenance in demanding applications. Evaluating your project's requirements for longevity and performance against initial expenditure will help determine the most cost-effective choice.

Performance in Extreme Conditions

Reinforced rubber exhibits superior performance in extreme conditions due to the embedded fibers or fabrics that enhance its tensile strength, resistance to punctures, and ability to withstand high pressure and temperature variations. Unreinforced rubber tends to degrade faster under extreme heat, cold, or mechanical stress, showing lower durability and elasticity in demanding environments. Industries requiring materials for harsh applications, such as automotive, aerospace, and heavy machinery, prefer reinforced rubber for its enhanced resilience and longer service life.

Maintenance and Lifespan

Reinforced rubber offers superior durability and requires less frequent maintenance due to its embedded fibers or fabric, which enhances resistance to wear, cracking, and pressure. Unreinforced rubber tends to have a shorter lifespan as it is more vulnerable to deformation and damage under stress, leading to more regular repairs or replacements. Choosing reinforced rubber for your applications can extend operational efficiency and reduce maintenance costs over time.

Choosing the Right Rubber for Your Needs

Reinforced rubber offers enhanced strength and durability through embedded fibers or fabric, making it ideal for high-stress applications like automotive tires and industrial hoses. Unreinforced rubber, being more flexible and softer, suits applications requiring elasticity and shock absorption such as seals and gaskets. Your choice depends on whether you prioritize toughness and longevity or flexibility and cushioning in your project.

Reinforced Rubber vs Unreinforced Rubber Infographic

libmatt.com

libmatt.com