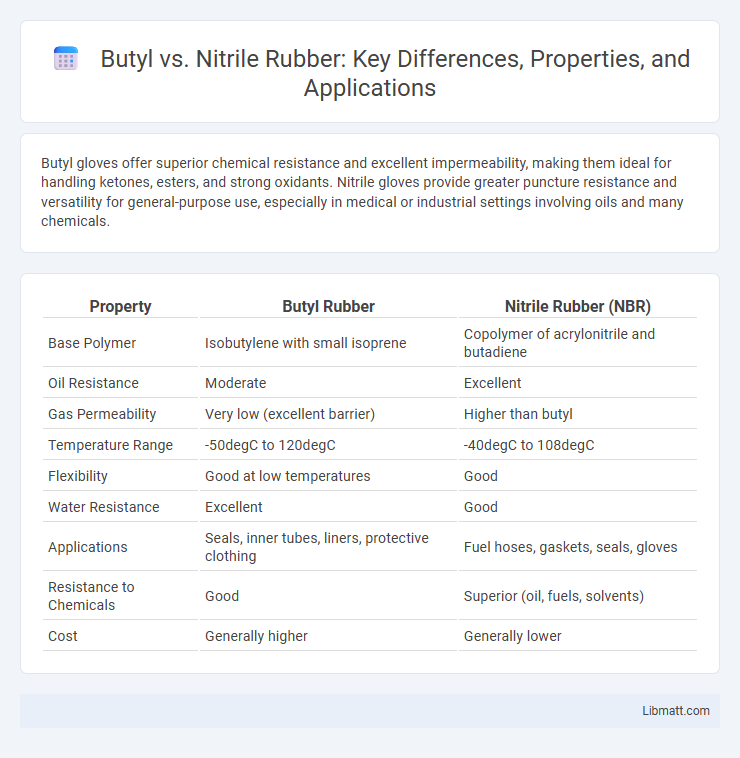

Butyl gloves offer superior chemical resistance and excellent impermeability, making them ideal for handling ketones, esters, and strong oxidants. Nitrile gloves provide greater puncture resistance and versatility for general-purpose use, especially in medical or industrial settings involving oils and many chemicals.

Table of Comparison

| Property | Butyl Rubber | Nitrile Rubber (NBR) |

|---|---|---|

| Base Polymer | Isobutylene with small isoprene | Copolymer of acrylonitrile and butadiene |

| Oil Resistance | Moderate | Excellent |

| Gas Permeability | Very low (excellent barrier) | Higher than butyl |

| Temperature Range | -50degC to 120degC | -40degC to 108degC |

| Flexibility | Good at low temperatures | Good |

| Water Resistance | Excellent | Good |

| Applications | Seals, inner tubes, liners, protective clothing | Fuel hoses, gaskets, seals, gloves |

| Resistance to Chemicals | Good | Superior (oil, fuels, solvents) |

| Cost | Generally higher | Generally lower |

Introduction to Butyl and Nitrile Materials

Butyl is a synthetic rubber known for its exceptional impermeability to gases, excellent resistance to heat, chemicals, and weathering, making it ideal for applications like inner tubes and protective gloves. Nitrile, or nitrile butadiene rubber (NBR), offers superior resistance to oils, fuels, and chemicals, commonly used in disposable gloves, seals, and automotive parts. Both materials provide unique benefits depending on their chemical resistance and durability requirements in various industrial and medical applications.

Chemical Composition of Butyl vs Nitrile

Butyl gloves are made from isobutylene and isoprene, creating a synthetic rubber with excellent resistance to gases and chemicals. Nitrile gloves consist of acrylonitrile and butadiene copolymers, offering superior puncture resistance and protection against oils and solvents. Your choice between butyl and nitrile depends on the specific chemical exposure and durability required for your application.

Key Properties: Butyl vs Nitrile

Butyl gloves are known for excellent chemical resistance, especially against acids, alkalis, and gases, offering superior impermeability and durability in harsh environments. Nitrile gloves provide outstanding puncture resistance and protection against oils, solvents, and certain chemicals, making them ideal for medical and industrial applications. When selecting between butyl and nitrile, your choice should consider exposure risks and required flexibility, as butyl excels in gas protection while nitrile offers higher mechanical strength.

Resistance to Chemicals and Solvents

Butyl gloves exhibit excellent resistance to a wide range of chemicals, including ketones, esters, and oxidizing agents, making them ideal for handling aggressive solvents and acidic substances. Nitrile gloves provide superior protection against oils, greases, and certain solvents like hydrocarbons but may degrade faster when exposed to ketones and aromatic hydrocarbons. Both materials offer distinct chemical resistance profiles, with butyl excelling in permeation resistance to polar solvents and nitrile providing robust defense against non-polar solvents and punctures.

Temperature Tolerance Comparison

Butyl gloves offer excellent temperature tolerance, maintaining flexibility and performance in temperatures ranging from -40degC to 120degC, making them ideal for extreme cold and heat environments. Nitrile gloves withstand temperatures between -25degC and 100degC, with strong resistance to heat but slightly less flexibility in colder conditions compared to butyl. Your choice depends on the temperature range of your application, with butyl gloves preferred for superior cold resistance and nitrile gloves suitable for moderate thermal protection combined with chemical resistance.

Applications and Industry Uses

Butyl gloves offer excellent chemical resistance and are widely used in the pharmaceutical, chemical processing, and automotive industries for handling hazardous substances. Nitrile gloves provide superior puncture resistance and are preferred in medical, food processing, and laboratory settings where durability and protection against oils and solvents are critical. Your choice between butyl and nitrile depends on the specific application requirements, including chemical exposure and required dexterity.

Durability and Longevity

Butyl gloves exhibit exceptional durability due to their superior resistance to chemicals, ozone, and extreme weather conditions, making them ideal for long-term use in hazardous environments. Nitrile gloves offer excellent puncture resistance and flexibility, but they tend to degrade faster under prolonged exposure to oils and solvents compared to butyl gloves. The extended lifespan of butyl gloves under harsh conditions makes them a preferred choice for applications requiring sustained protection.

Cost and Availability

Butyl gloves generally cost more than nitrile gloves due to their specialized chemical resistance and durability, making them suitable for niche applications. Nitrile gloves offer a more cost-effective and widely available option, commonly used in medical, industrial, and general-purpose settings. Your choice between butyl and nitrile may depend on balancing budget constraints with the need for specific chemical protection.

Environmental and Safety Considerations

Butyl gloves offer superior chemical resistance and low permeability to gases, making them ideal for handling hazardous substances with minimal environmental impact due to their durability and reduced need for frequent replacement. Nitrile gloves provide excellent puncture resistance and are free from natural latex proteins, reducing the risk of allergic reactions and ensuring safer use in medical and industrial settings. Both materials are recyclable under specific programs, but nitrile's increased popularity has driven more initiatives toward sustainable disposal and reduced environmental footprint.

Choosing the Right Material: Butyl or Nitrile

Selecting between butyl and nitrile rubber depends on the specific application requirements such as chemical resistance, flexibility, and temperature tolerance. Butyl excels in superior impermeability to gases and excellent resistance to ozone, weathering, and heat, making it ideal for applications like inner tubes and protective clothing. Nitrile offers outstanding resistance to oils, fuels, and other hydrocarbons, plus good abrasion resistance, which makes it the preferred choice for automotive, industrial gloves, and fuel handling equipment.

Butyl vs Nitrile Infographic

libmatt.com

libmatt.com