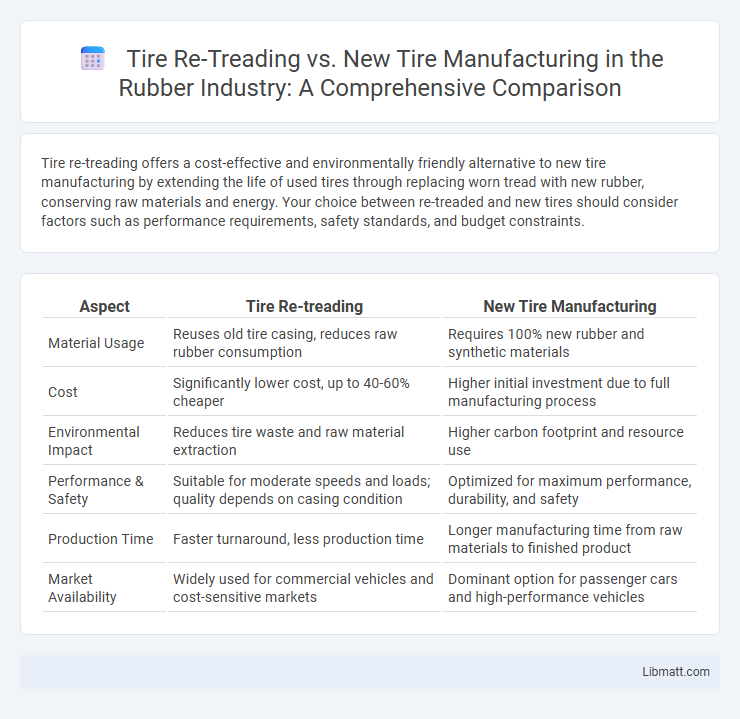

Tire re-treading offers a cost-effective and environmentally friendly alternative to new tire manufacturing by extending the life of used tires through replacing worn tread with new rubber, conserving raw materials and energy. Your choice between re-treaded and new tires should consider factors such as performance requirements, safety standards, and budget constraints.

Table of Comparison

| Aspect | Tire Re-treading | New Tire Manufacturing |

|---|---|---|

| Material Usage | Reuses old tire casing, reduces raw rubber consumption | Requires 100% new rubber and synthetic materials |

| Cost | Significantly lower cost, up to 40-60% cheaper | Higher initial investment due to full manufacturing process |

| Environmental Impact | Reduces tire waste and raw material extraction | Higher carbon footprint and resource use |

| Performance & Safety | Suitable for moderate speeds and loads; quality depends on casing condition | Optimized for maximum performance, durability, and safety |

| Production Time | Faster turnaround, less production time | Longer manufacturing time from raw materials to finished product |

| Market Availability | Widely used for commercial vehicles and cost-sensitive markets | Dominant option for passenger cars and high-performance vehicles |

Introduction to Tire Re-treading and New Tire Manufacturing

Tire re-treading involves refurbishing worn tire casings by applying new tread rubber, extending tire life and reducing costs, primarily used in commercial and heavy-duty vehicles. New tire manufacturing utilizes raw materials such as natural and synthetic rubber, steel, and fabric to create entirely new tires through processes including mixing, calendaring, extrusion, and vulcanization. Both methods serve different market needs, with re-treading emphasizing sustainability and cost efficiency, while new tire production focuses on performance, safety, and technological advancements.

Overview of the Tire Production Process

Tire re-treading involves refurbishing worn tire casings by replacing the tread, extending the tire's lifespan and reducing material waste, while new tire manufacturing starts from raw rubber and synthetic compounds molded into a complete tire structure. The production of new tires includes stages such as mixing raw materials, building tire components, curing in molds, and rigorous quality testing, ensuring durability and performance. Your decision between these options impacts environmental sustainability and cost efficiency within commercial and consumer vehicle fleets.

Environmental Impact: Re-treading vs New Tire Manufacturing

Tire re-treading significantly reduces environmental impact by conserving raw materials, lowering energy consumption, and minimizing waste compared to new tire manufacturing. Producing a new tire requires extracting and processing large quantities of natural rubber, synthetic materials, and petroleum-based products, resulting in higher greenhouse gas emissions and resource depletion. Re-treaded tires extend tire life cycles, decrease landfill waste, and contribute to a more sustainable tire industry by reducing the carbon footprint associated with tire production.

Cost Analysis: Re-treaded Tires vs New Tires

Re-treaded tires typically cost 30-50% less than new tires, offering significant savings for fleet operators and commercial vehicle owners. While new tires provide longer lifespan and advanced tread technology, re-treading maximizes the use of existing casings, reducing raw material consumption and environmental impact. Cost efficiency of re-treaded tires makes them an attractive choice in industries prioritizing budget management without compromising safety standards.

Performance and Safety Comparison

Tire re-treading offers a cost-effective solution by refurbishing worn tires with new tread, but new tire manufacturing ensures optimal performance through advanced materials and design technology that enhance grip, durability, and resistance to wear. Safety tests reveal that new tires consistently provide better handling, braking efficiency, and resistance to hydroplaning under diverse driving conditions, reducing accident risk. While re-treaded tires meet safety standards for specific uses, they may not deliver the same level of performance and reliability as brand-new tires engineered for maximum safety and endurance.

Longevity and Durability Considerations

Tire re-treading offers a cost-effective solution by extending the life of existing tire casings, providing sufficient durability for moderate usage and reducing environmental impact through resource conservation. New tire manufacturing employs advanced materials and engineering techniques that enhance longevity, resistance to wear, and performance under diverse road conditions. While re-treaded tires may have a shorter lifespan compared to new tires, their quality depends heavily on the condition of the original casing and the retreading process used.

Regulatory Standards and Industry Certification

Tire re-treading and new tire manufacturing adhere to stringent regulatory standards set by authorities such as the U.S. Department of Transportation (DOT) and the European Tyre and Rim Technical Organisation (ETRTO). Industry certifications like the Tire Retread & Repair Information Bureau (TRIB) for re-treads and ISO/TS 16949 for new tire production ensure compliance with safety, performance, and environmental requirements. Understanding these certifications helps you make informed decisions about the reliability and quality of re-treaded versus new tires.

Commercial and Fleet Applications

Tire re-treading offers commercial and fleet operators a cost-effective and environmentally sustainable alternative to new tire manufacturing, significantly reducing raw material consumption and waste. Fleet managers benefit from extended tire life cycles and reduced downtime due to faster turnaround times in the retreading process. New tire manufacturing delivers superior performance and durability for heavy-duty applications but involves higher initial investment and environmental impact compared to re-treaded options.

Consumer Perception and Market Trends

Consumer perception of tire re-treading often centers on cost-effectiveness and environmental benefits, appealing to budget-conscious and eco-friendly buyers. Market trends show a gradual increase in acceptance of re-treaded tires within commercial fleets due to regulatory support and improved retreading technologies. Your choice between re-treaded and new tires can significantly impact long-term expenses and sustainability goals.

Future Developments in Tire Sustainability

Emerging technologies in tire re-treading are enhancing sustainability by reducing raw material consumption and lowering carbon emissions compared to new tire manufacturing. Innovations in bio-based materials and improved retread processes extend the lifecycle of tires, offering a circular economy model that benefits Your environmental footprint. Future developments prioritize eco-friendly designs and energy-efficient production methods, driving a shift toward more sustainable tire solutions.

Tire Re-treading vs New Tire Manufacturing Infographic

libmatt.com

libmatt.com