Two roll mills provide precise control over the mixing and milling process, ideal for small-scale productions and materials requiring thorough blending, while internal mixers offer superior efficiency and consistency for large-batch mixing with better temperature control. Choosing the right equipment depends on your production volume, specific material properties, and desired outcomes in product quality.

Table of Comparison

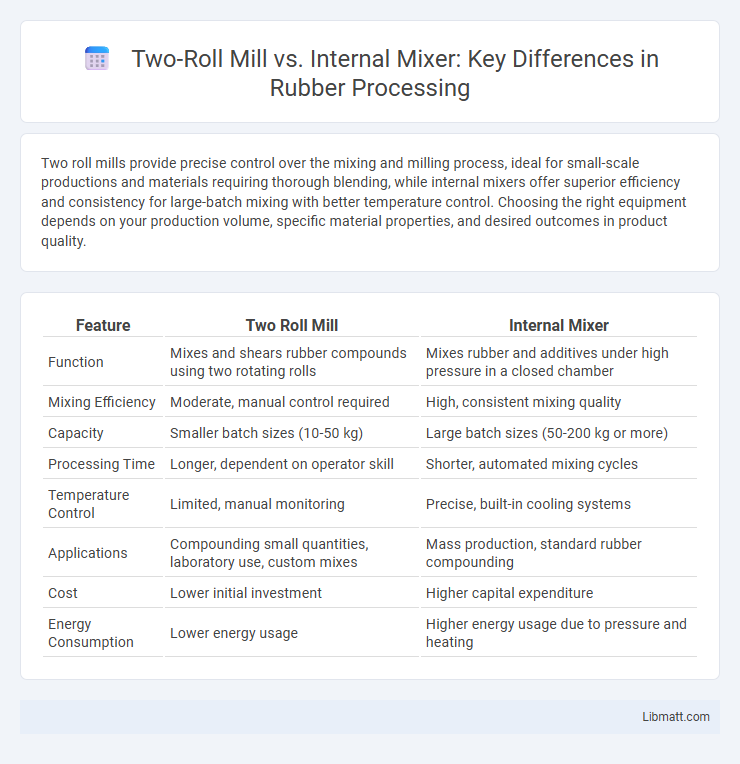

| Feature | Two Roll Mill | Internal Mixer |

|---|---|---|

| Function | Mixes and shears rubber compounds using two rotating rolls | Mixes rubber and additives under high pressure in a closed chamber |

| Mixing Efficiency | Moderate, manual control required | High, consistent mixing quality |

| Capacity | Smaller batch sizes (10-50 kg) | Large batch sizes (50-200 kg or more) |

| Processing Time | Longer, dependent on operator skill | Shorter, automated mixing cycles |

| Temperature Control | Limited, manual monitoring | Precise, built-in cooling systems |

| Applications | Compounding small quantities, laboratory use, custom mixes | Mass production, standard rubber compounding |

| Cost | Lower initial investment | Higher capital expenditure |

| Energy Consumption | Lower energy usage | Higher energy usage due to pressure and heating |

Introduction to Two Roll Mill and Internal Mixer

Two roll mills consist of two horizontally opposed, rotating rolls with precise speed control, primarily used for mixing and sheeting rubber and plastic compounds. Internal mixers feature a closed chamber with rotating rotors that shear and blend materials under controlled temperature and pressure, optimizing compound homogeneity. Both machines are essential in polymer processing, with two roll mills favored for open mixing and shaping, while internal mixers excel in high-efficiency, enclosed mixing.

Key Differences Between Two Roll Mill and Internal Mixer

Two Roll Mill operates with two rotating rolls to mix and process rubber or plastic, offering precise control over thickness and texture, while an Internal Mixer uses a closed chamber with rotating rotors for high-efficiency, uniform blending under controlled temperature and pressure. You benefit from Two Roll Mill's superior surface mixing suited for small batches and detailed compounding, whereas the Internal Mixer excels in large-scale production with better energy efficiency and faster mixing cycles. Key differences include batch size capacity, mixing uniformity, temperature control, and operational complexity, influencing your choice based on production scale and material requirements.

Working Principle of Two Roll Mill

The working principle of a Two Roll Mill involves the material being fed between two horizontally positioned rotating rolls that compress and shear the material, enabling uniform mixing and dispersion. The differential speed of the rolls creates a shearing action that improves the homogenization of polymers, rubbers, or chemicals. This method offers precise control over temperature and thickness, essential for processing heat-sensitive and viscous materials.

Working Principle of Internal Mixer

The internal mixer operates by combining raw materials in a rotating chamber where high shear forces and temperature facilitate efficient mixing and melting of polymers. Unlike the open Two Roll Mill, the internal mixer's enclosed environment ensures uniform dispersion of additives and fillers through intense mechanical action between intermeshing rotors. This controlled mixing process enhances material homogeneity, making it ideal for compounding rubber and plastics with precise formulation requirements.

Material Mixing Efficiency Comparison

Two roll mills provide precise shear and elongation forces ideal for mixing rubber compounds with fillers, promoting uniform dispersion at lower energy consumption. Internal mixers generate intense internal friction and high shear, enabling faster and more homogeneous mixing of viscous materials such as elastomers and thermoplastics. While internal mixers offer superior mixing speed and consistency for complex blends, two roll mills excel in fine-tuning material properties through controlled, incremental mixing stages.

Advantages of Two Roll Mill

Two roll mills offer precise control over thickness and improved mixing uniformity, making them ideal for processing rubber and plastics. They enable continuous operation with minimal material waste and provide better heat dissipation during compounding. Their simplicity and lower maintenance costs contribute to higher efficiency in small to medium-scale production environments.

Advantages of Internal Mixer

Internal mixers offer superior mixing efficiency and consistency compared to two roll mills, ensuring uniform dispersion of materials in your compounds. They provide better control over temperature and mixing speed, which enhances product quality and reduces processing time. The enclosed design also minimizes contamination and improves safety during operation.

Common Applications in the Rubber and Plastics Industry

Two roll mills are commonly used in the rubber and plastics industry for mixing, sheeting, and blending raw materials, particularly in small batch production and laboratory settings. Internal mixers excel in high-volume production, efficiently mixing rubber compounds with fillers, plasticizers, and curing agents under controlled temperature and pressure conditions. Both machines play critical roles in preparing homogeneous materials for subsequent processing like extrusion, molding, and calendering.

Factors to Consider When Choosing Between Two Roll Mill and Internal Mixer

Key factors to consider when choosing between a Two Roll Mill and an Internal Mixer include the material type, batch size, and mixing precision required. Two Roll Mills offer superior control for blending and milling rubber or plastics in smaller batches, while Internal Mixers provide consistent and efficient mixing for larger volumes with better temperature control. Production speed, energy consumption, and maintenance complexity also influence the decision depending on the specific manufacturing process and product specifications.

Conclusion: Selecting the Right Mixing Equipment

Choosing between a Two Roll Mill and an Internal Mixer depends on your material type and production scale. Two Roll Mills offer precise control for small to medium batches, ideal for custom rubber or polymer compounding. Internal Mixers excel in large-scale, high-intensity mixing, ensuring uniform dispersion and efficient processing for your industrial needs.

Two Roll Mill vs Internal Mixer Infographic

libmatt.com

libmatt.com