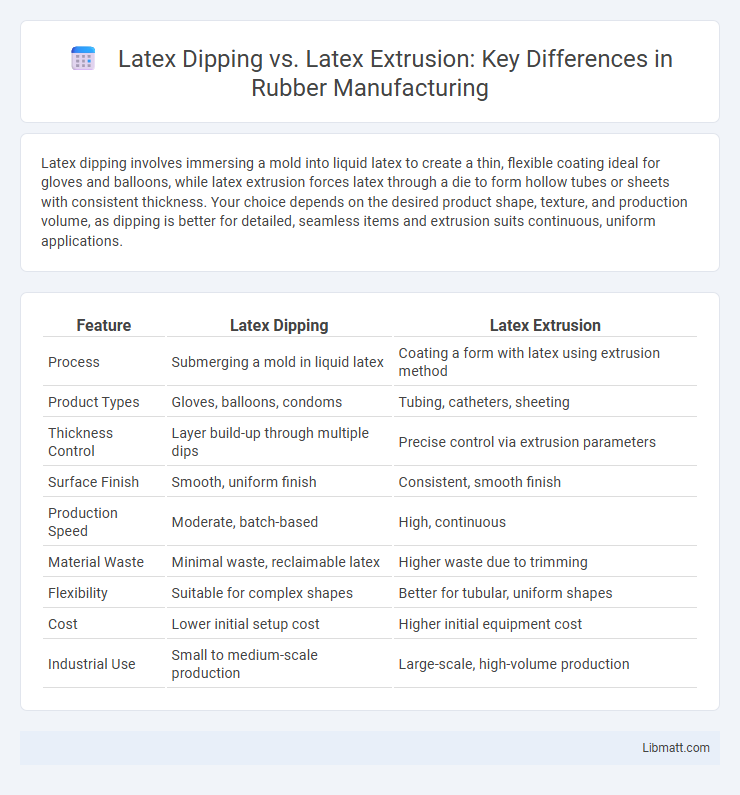

Latex dipping involves immersing a mold into liquid latex to create a thin, flexible coating ideal for gloves and balloons, while latex extrusion forces latex through a die to form hollow tubes or sheets with consistent thickness. Your choice depends on the desired product shape, texture, and production volume, as dipping is better for detailed, seamless items and extrusion suits continuous, uniform applications.

Table of Comparison

| Feature | Latex Dipping | Latex Extrusion |

|---|---|---|

| Process | Submerging a mold in liquid latex | Coating a form with latex using extrusion method |

| Product Types | Gloves, balloons, condoms | Tubing, catheters, sheeting |

| Thickness Control | Layer build-up through multiple dips | Precise control via extrusion parameters |

| Surface Finish | Smooth, uniform finish | Consistent, smooth finish |

| Production Speed | Moderate, batch-based | High, continuous |

| Material Waste | Minimal waste, reclaimable latex | Higher waste due to trimming |

| Flexibility | Suitable for complex shapes | Better for tubular, uniform shapes |

| Cost | Lower initial setup cost | Higher initial equipment cost |

| Industrial Use | Small to medium-scale production | Large-scale, high-volume production |

Introduction to Latex Dipping and Latex Extrusion

Latex dipping involves immersing molds directly into liquid latex to create seamless, flexible products such as gloves and balloons, offering precise thickness control and smooth finishes. Latex extrusion pushes liquid latex through a die to form continuous sheets or tubular shapes, ideal for producing films, tubing, and other uniform latex items with consistent dimensions. Your choice between dipping and extrusion depends on the desired product design and manufacturing efficiency.

Understanding the Latex Dipping Process

The latex dipping process involves submerging a mold repeatedly into liquid latex to build up layers, allowing precise control over thickness and texture for products like gloves and balloons. It creates a uniform coating by curing each layer, which enhances durability and elasticity essential for high-performance applications. Latex dipping is preferred for its ability to produce seamless, flexible items with consistent quality compared to latex extrusion methods.

Overview of Latex Extrusion Technology

Latex extrusion technology involves shaping liquid natural rubber by forcing it through a die to create continuous, hollow, or solid profiles with precise dimensions, used in products like gloves, tubing, and catheters. This method ensures uniform wall thickness and consistent quality, enabling high production speeds and reduced material waste compared to latex dipping. Your manufacturing process can benefit from latex extrusion by achieving exact control over product specifications and improving efficiency for medical and industrial applications.

Key Differences Between Dipping and Extrusion

Latex dipping involves immersing a form into liquid latex to create thin, seamless coatings ideal for gloves and balloons, while latex extrusion pushes latex through a shaped die, producing continuous sheets or tubes with uniform thickness. Dipping allows for intricate detail and flexibility in thickness, whereas extrusion excels in high-volume production with consistent dimensions. The key differences hinge on product complexity, production speed, and application-specific material properties.

Advantages of Latex Dipping

Latex dipping offers superior precision in producing thin, flexible coatings ideal for medical gloves and condoms, with excellent elasticity and barrier properties. This process allows for consistent thickness control and smooth surface finishes, enhancing comfort and durability for Your protective gear. Latex dipping is also more cost-effective for small to medium-scale production runs, minimizing waste compared to extrusion methods.

Benefits of Latex Extrusion

Latex extrusion offers superior consistency and precision in producing thin, uniform latex coatings compared to latex dipping, reducing material waste and improving product quality. This method enhances control over layer thickness and surface finish, resulting in stronger, more durable latex products ideal for medical and industrial applications. Automation in latex extrusion also increases production speed and scalability, meeting high-volume manufacturing demands efficiently.

Typical Applications of Dipped Latex Products

Typical applications of dipped latex products include medical gloves, balloons, condoms, and household gloves due to their flexibility, durability, and cost-effectiveness. Dipped latex items are widely used in healthcare, hygiene, and consumer goods industries where thin, elastic, and form-fitting materials are essential. The dipping process allows for precise control over thickness, making it ideal for products requiring tactile sensitivity and barrier protection.

Common Uses for Extruded Latex Items

Extruded latex products are commonly used in applications requiring consistent thickness and durability, such as medical tubing, elastic bands, and seals. Their uniform shape and smooth surface make them ideal for manufacturing gloves, catheters, and weatherstripping where precision and flexibility are crucial. You can rely on extruded latex items for products needing high elasticity and resistance to wear in various industrial and healthcare settings.

Factors Influencing Method Selection

Factors influencing the selection between latex dipping and latex extrusion include product complexity, desired wall thickness uniformity, and production volume. Latex dipping offers superior flexibility for producing intricate shapes and variable thicknesses, while latex extrusion provides consistent, uniform tubing ideal for high-volume manufacturing. Material properties, cost constraints, and post-processing requirements also play critical roles in determining the optimal method for latex product fabrication.

Future Trends in Latex Manufacturing Techniques

Future trends in latex manufacturing techniques emphasize increased automation and sustainability, with latex dipping evolving to incorporate robotic precision for consistent thickness and reduced waste. Latex extrusion is advancing through the integration of bio-based latex compounds and energy-efficient processes to minimize environmental impact. Innovations in nanotechnology and real-time quality monitoring are driving improvements in product durability and manufacturing efficiency across both techniques.

Latex Dipping vs Latex Extrusion Infographic

libmatt.com

libmatt.com