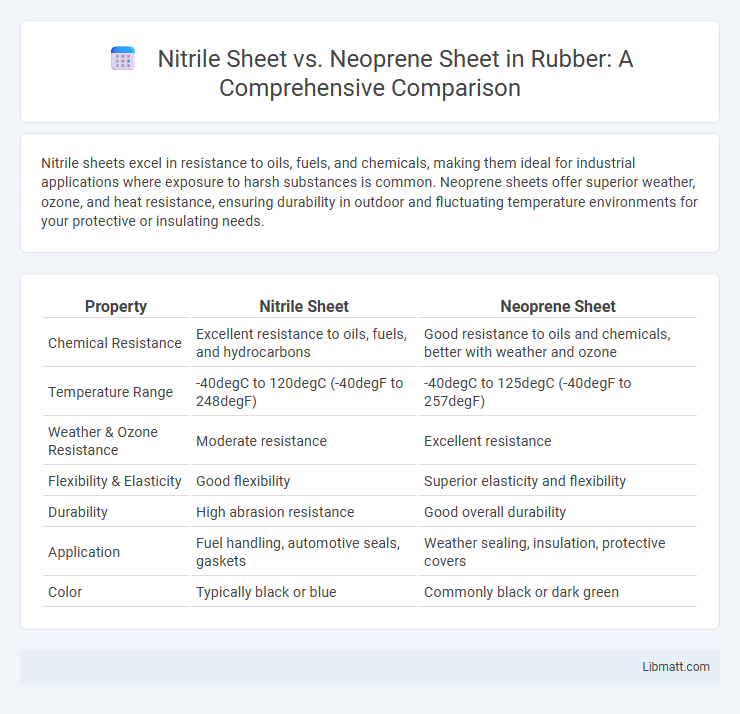

Nitrile sheets excel in resistance to oils, fuels, and chemicals, making them ideal for industrial applications where exposure to harsh substances is common. Neoprene sheets offer superior weather, ozone, and heat resistance, ensuring durability in outdoor and fluctuating temperature environments for your protective or insulating needs.

Table of Comparison

| Property | Nitrile Sheet | Neoprene Sheet |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and hydrocarbons | Good resistance to oils and chemicals, better with weather and ozone |

| Temperature Range | -40degC to 120degC (-40degF to 248degF) | -40degC to 125degC (-40degF to 257degF) |

| Weather & Ozone Resistance | Moderate resistance | Excellent resistance |

| Flexibility & Elasticity | Good flexibility | Superior elasticity and flexibility |

| Durability | High abrasion resistance | Good overall durability |

| Application | Fuel handling, automotive seals, gaskets | Weather sealing, insulation, protective covers |

| Color | Typically black or blue | Commonly black or dark green |

Introduction to Nitrile and Neoprene Sheets

Nitrile sheets, made from synthetic rubber known as NBR, excel in oil resistance, fuel exposure, and chemical handling, making them ideal for automotive and industrial applications. Neoprene sheets, derived from polychloroprene, offer superior weather, ozone, and flame resistance, commonly used in protective gear, gaskets, and sealants. Both materials provide flexibility and durability, but nitrile prioritizes chemical resistance while neoprene emphasizes environmental resilience.

Material Composition: Nitrile vs Neoprene

Nitrile sheets are composed primarily of synthetic copolymers of acrylonitrile and butadiene, offering excellent resistance to oils, fuels, and chemicals due to their high nitrile content. Neoprene sheets consist of polychloroprene, a chlorinated polymer known for its balanced properties including good weather, ozone, and chemical resistance along with flexibility. The distinct molecular structures dictate their performance, with nitrile excelling in hydrocarbon exposure while neoprene provides broader environmental durability.

Key Physical Properties Comparison

Nitrile sheets offer exceptional resistance to oils, fuels, and chemicals with a tensile strength of 14-25 MPa and elongation at break ranging from 300% to 600%. Neoprene sheets provide good weathering, ozone, and flame resistance, with a tensile strength typically between 6-20 MPa and elongation at break of 200% to 600%. In terms of hardness, nitrile sheets generally range from 40 to 90 Shore A, while neoprene sheets range from 40 to 70 Shore A, impacting their flexibility and durability in diverse industrial applications.

Chemical Resistance: Nitrile vs Neoprene

Nitrile sheets exhibit superior resistance to oils, fuels, and hydrocarbons, making them ideal for applications requiring protection against petroleum-based chemicals. Neoprene sheets offer excellent resistance to weathering, ozone, and moderate exposure to acids and chemicals but are less effective against strong oils and solvents compared to nitrile. Selecting between nitrile and neoprene sheets depends on the specific chemical environment, with nitrile preferred for hydrocarbon resistance and neoprene favored for environmental durability.

Temperature Resistance and Stability

Nitrile sheets offer excellent resistance to temperatures up to 120degC while maintaining chemical stability, making them ideal for exposure to oils and fuels. Neoprene sheets withstand a broader temperature range, typically from -40degC to 120degC, providing superior flexibility and durability in fluctuating environments. Your choice depends on the specific temperature range and chemical exposure to ensure optimal stability in application.

Applications and Industry Use Cases

Nitrile sheets excel in oil resistance, making them ideal for automotive seals, fuel handling, and gaskets in the petroleum industry. Neoprene sheets offer superior weather, ozone, and chemical resistance, widely used in marine, construction, and refrigeration applications. Both materials are crucial in industrial manufacturing, with nitrile favored for its durability against oils and neoprene for versatility in environmental exposure.

Durability and Longevity

Nitrile sheets offer superior resistance to oils, fuels, and chemicals, making them highly durable in industrial environments where exposure to such substances is common. Neoprene sheets provide excellent weathering and ozone resistance, ensuring long-lasting performance in outdoor applications with moderate chemical exposure. The choice between nitrile and neoprene sheets depends on the specific environmental factors and chemical agents they will encounter, directly impacting their longevity.

Cost and Availability Differences

Nitrile sheets are generally more cost-effective than neoprene sheets, making them a preferred choice for budget-conscious applications. You will find nitrile sheets widely available due to their extensive use in oil-resistant and industrial settings, whereas neoprene sheets, known for their weather and chemical resistance, may be less readily stocked but offer superior durability. Cost differences reflect varying performance benefits, with nitrile offering affordability and availability, and neoprene providing better longevity and flexibility in specialized environments.

Environmental Impact and Safety

Nitrile sheets offer superior resistance to oils and chemicals, making them safer for industrial applications where exposure to hazardous substances is a concern. Neoprene sheets, while moderately chemical-resistant, provide better weathering and ozone resistance, which reduces environmental degradation over time. You should consider nitrile for applications prioritizing chemical safety and neoprene for long-term environmental durability.

Choosing the Right Sheet for Your Needs

Nitrile sheets offer excellent resistance to oils, fuels, and chemicals, making them ideal for automotive and industrial applications where oil exposure is frequent. Neoprene sheets provide superior weather, ozone, and flame resistance, suitable for outdoor environments and general-purpose gasketing. Assess your specific requirements for chemical exposure and environmental conditions to select the right sheet material that ensures durability and performance.

Nitrile Sheet vs Neoprene Sheet Infographic

libmatt.com

libmatt.com