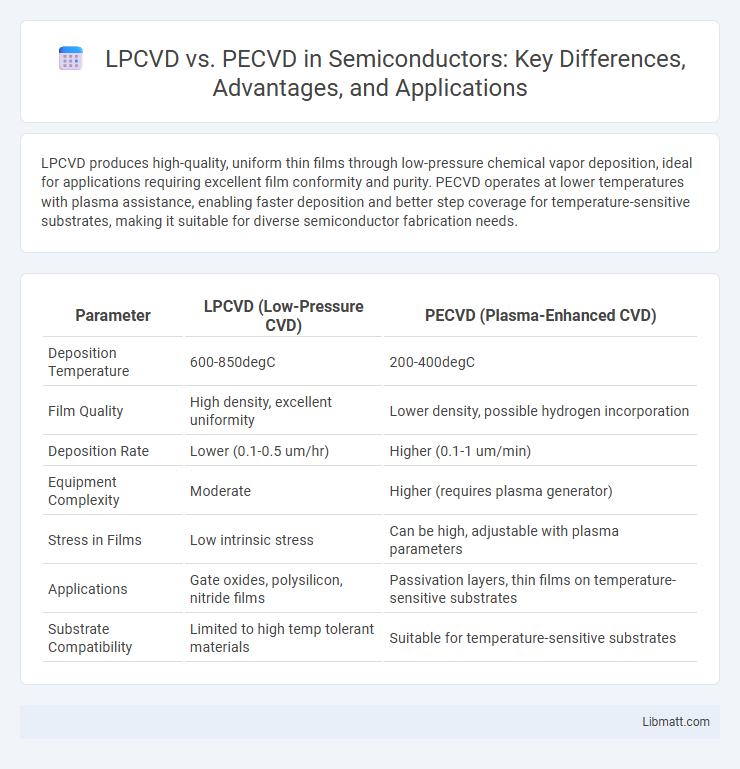

LPCVD produces high-quality, uniform thin films through low-pressure chemical vapor deposition, ideal for applications requiring excellent film conformity and purity. PECVD operates at lower temperatures with plasma assistance, enabling faster deposition and better step coverage for temperature-sensitive substrates, making it suitable for diverse semiconductor fabrication needs.

Table of Comparison

| Parameter | LPCVD (Low-Pressure CVD) | PECVD (Plasma-Enhanced CVD) |

|---|---|---|

| Deposition Temperature | 600-850degC | 200-400degC |

| Film Quality | High density, excellent uniformity | Lower density, possible hydrogen incorporation |

| Deposition Rate | Lower (0.1-0.5 um/hr) | Higher (0.1-1 um/min) |

| Equipment Complexity | Moderate | Higher (requires plasma generator) |

| Stress in Films | Low intrinsic stress | Can be high, adjustable with plasma parameters |

| Applications | Gate oxides, polysilicon, nitride films | Passivation layers, thin films on temperature-sensitive substrates |

| Substrate Compatibility | Limited to high temp tolerant materials | Suitable for temperature-sensitive substrates |

Overview of LPCVD and PECVD Technologies

LPCVD (Low Pressure Chemical Vapor Deposition) operates at reduced pressures, providing highly uniform and conformal thin films essential for semiconductor manufacturing. PECVD (Plasma Enhanced Chemical Vapor Deposition) uses plasma to enhance chemical reactions at lower temperatures, enabling deposition on temperature-sensitive substrates. Your choice between LPCVD and PECVD depends on process temperature constraints, film quality requirements, and material compatibility for specific applications.

Fundamental Principles: LPCVD vs PECVD

LPCVD (Low Pressure Chemical Vapor Deposition) operates by decomposing gaseous precursors at elevated temperatures under low pressure, promoting uniform thin-film growth with high conformality. PECVD (Plasma-Enhanced Chemical Vapor Deposition) utilizes plasma to energize the chemical reactions at lower temperatures, enabling deposition on temperature-sensitive substrates. Your choice between LPCVD and PECVD depends on required film quality, thermal budget, and substrate compatibility.

Key Process Differences

LPCVD (Low Pressure Chemical Vapor Deposition) operates at lower pressures and higher temperatures, typically between 500-900degC, producing highly conformal and dense thin films ideal for microelectronic applications. PECVD (Plasma-Enhanced Chemical Vapor Deposition) uses plasma to enhance chemical reactions at lower temperatures, around 200-400degC, enabling deposition on temperature-sensitive substrates. The fundamental difference lies in LPCVD's reliance on thermal energy for film growth versus PECVD's plasma-assisted process, impacting deposition rates, film stress, and material properties.

Material Deposition Capabilities

LPCVD (Low Pressure Chemical Vapor Deposition) excels in producing high-quality, uniform, and dense films such as polysilicon, silicon nitride, and silicon dioxide ideal for MEMS and semiconductor applications due to its high temperature process. PECVD (Plasma Enhanced Chemical Vapor Deposition) enables deposition of diverse materials at lower temperatures, including silicon nitride, silicon oxide, amorphous silicon, and various dielectrics, suitable for temperature-sensitive substrates and flexible electronics. LPCVD typically delivers superior conformality and film density, while PECVD offers greater process flexibility with faster deposition rates and tailored film properties through plasma control.

Deposition Rate Comparison

LPCVD (Low-Pressure Chemical Vapor Deposition) typically exhibits lower deposition rates, ranging from 10 to 100 nm/min, compared to PECVD (Plasma-Enhanced Chemical Vapor Deposition), which achieves higher rates of 50 to 500 nm/min due to plasma-assisted reactions at lower temperatures. LPCVD offers superior film uniformity and conformality ideal for high-quality applications, while PECVD's higher deposition rates enable faster processing suited for temperature-sensitive substrates. The choice between LPCVD and PECVD depends on the balance between deposition speed, film quality, and substrate compatibility requirements.

Film Uniformity and Quality

LPCVD (Low Pressure Chemical Vapor Deposition) offers superior film uniformity and higher-quality films due to its low-pressure environment and thermal-driven reactions, resulting in dense, defect-free layers ideal for semiconductor applications. PECVD (Plasma-Enhanced Chemical Vapor Deposition) enables film deposition at lower temperatures, enhancing compatibility with temperature-sensitive substrates but may produce films with slightly less uniformity and higher hydrogen content. Your choice hinges on the balance between thermal budget constraints and the required film integrity for device performance.

Temperature Requirements and Substrate Compatibility

LPCVD (Low-Pressure Chemical Vapor Deposition) operates at high temperatures typically between 550degC and 900degC, making it suitable for substrates that withstand elevated thermal budgets such as silicon wafers. PECVD (Plasma-Enhanced Chemical Vapor Deposition) functions at significantly lower temperatures, generally ranging from 200degC to 400degC, allowing deposition on thermally sensitive substrates like polymers and glass. The lower thermal requirements of PECVD expand its compatibility with a wider array of materials, while LPCVD provides high-quality films on heat-tolerant substrates.

Applications in Semiconductor Manufacturing

LPCVD (Low Pressure Chemical Vapor Deposition) and PECVD (Plasma Enhanced Chemical Vapor Deposition) are crucial techniques in semiconductor manufacturing for depositing thin films. LPCVD is widely used for producing high-quality silicon nitride, polysilicon, and silicon dioxide layers in microelectronic devices due to its uniformity and conformality at elevated temperatures. PECVD offers advantages in depositing dielectric films at lower temperatures, enabling integration with temperature-sensitive substrates and applications such as passivation layers and interlayer dielectrics in advanced integrated circuits.

Advantages and Limitations

LPCVD offers superior uniformity and high-quality conformal films with excellent step coverage, making it ideal for complex 3D structures, but operates at high temperatures that may damage temperature-sensitive substrates. PECVD enables lower temperature deposition, suitable for heat-sensitive materials and faster processing times, though it typically results in films with higher hydrogen content and less density compared to LPCVD films. The choice depends on balancing thermal budget constraints, film quality requirements, and throughput needs in semiconductor or MEMS fabrication.

Choosing Between LPCVD and PECVD

Selecting between LPCVD (Low Pressure Chemical Vapor Deposition) and PECVD (Plasma Enhanced Chemical Vapor Deposition) depends on factors such as temperature sensitivity, film quality, and deposition rate. LPCVD operates at higher temperatures, offering superior film uniformity and density, ideal for applications demanding high-quality silicon nitride or polysilicon layers. PECVD enables lower temperature processing with faster deposition rates and better control over film stress, making it suitable for temperature-sensitive substrates and complex multilayer structures.

LPCVD vs PECVD Infographic

libmatt.com

libmatt.com