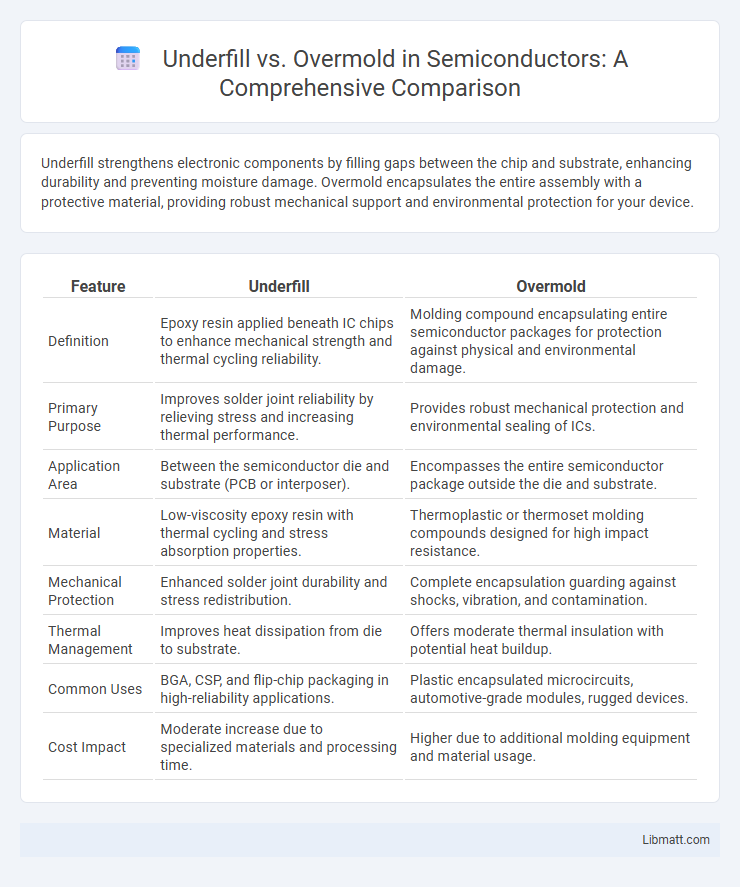

Underfill strengthens electronic components by filling gaps between the chip and substrate, enhancing durability and preventing moisture damage. Overmold encapsulates the entire assembly with a protective material, providing robust mechanical support and environmental protection for your device.

Table of Comparison

| Feature | Underfill | Overmold |

|---|---|---|

| Definition | Epoxy resin applied beneath IC chips to enhance mechanical strength and thermal cycling reliability. | Molding compound encapsulating entire semiconductor packages for protection against physical and environmental damage. |

| Primary Purpose | Improves solder joint reliability by relieving stress and increasing thermal performance. | Provides robust mechanical protection and environmental sealing of ICs. |

| Application Area | Between the semiconductor die and substrate (PCB or interposer). | Encompasses the entire semiconductor package outside the die and substrate. |

| Material | Low-viscosity epoxy resin with thermal cycling and stress absorption properties. | Thermoplastic or thermoset molding compounds designed for high impact resistance. |

| Mechanical Protection | Enhanced solder joint durability and stress redistribution. | Complete encapsulation guarding against shocks, vibration, and contamination. |

| Thermal Management | Improves heat dissipation from die to substrate. | Offers moderate thermal insulation with potential heat buildup. |

| Common Uses | BGA, CSP, and flip-chip packaging in high-reliability applications. | Plastic encapsulated microcircuits, automotive-grade modules, rugged devices. |

| Cost Impact | Moderate increase due to specialized materials and processing time. | Higher due to additional molding equipment and material usage. |

Introduction to Underfill and Overmold

Underfill and overmold techniques serve distinct roles in electronics assembly, enhancing device reliability and protection. Underfill involves applying a liquid epoxy between a chip and its substrate to reinforce solder joints and improve thermal cycling resistance. Overmold encapsulates components with a protective polymer, providing robust environmental and mechanical protection.

Key Differences Between Underfill and Overmold

Underfill and overmold are essential processes in electronics packaging, with key differences in application and purpose. Underfill is a low-viscosity epoxy used to fill the gap between a chip and substrate, enhancing mechanical strength and thermal cycling reliability. Overmold, typically a molded plastic compound, encapsulates the entire component for environmental protection and mechanical support, ensuring your device's durability under harsh conditions.

Applications of Underfill in Electronics

Underfill is primarily used in advanced electronics packaging to enhance the mechanical strength and reliability of flip-chip assemblies by filling the gap between the chip and substrate, thereby reducing stress from thermal expansion differences. It is critical in applications such as high-performance computing, mobile devices, and automotive electronics, where durability and long-term reliability under thermal cycling are essential. Underfill improves thermal conductivity and protects delicate solder joints from mechanical shock, vibration, and moisture ingress, ensuring device longevity in demanding environments.

Applications of Overmold in Manufacturing

Overmold in manufacturing is widely applied in creating ergonomic consumer products, such as tool handles and wearable devices, by providing enhanced grip and comfort through flexible materials bonded to rigid substrates. It is essential in automotive components, offering improved durability, vibration damping, and aesthetic finishes to parts like dashboard controls and exterior trims. Overmolding also plays a critical role in medical device production by combining biocompatible materials into complex geometries to ensure patient safety and device functionality.

Material Selection: Underfill vs Overmold

Material selection for underfill primarily involves low-viscosity epoxy resins designed to flow into narrow gaps and provide mechanical support between components, whereas overmold materials typically include thermoplastic or thermoset polymers that offer thicker, protective coatings and enhanced environmental resistance. Underfill materials emphasize thermal conductivity and stress relief to improve electronic reliability, while overmold materials prioritize durability, impact resistance, and sealing properties for overall device protection. Your choice depends on whether the priority is structural reinforcement within electronic assemblies or robust external encapsulation.

Performance Benefits: Underfill vs Overmold

Underfill enhances electronic assembly reliability by providing superior stress distribution and protecting solder joints from thermal cycling and mechanical shock, making it ideal for fine-pitch components in high-reliability applications. Overmold offers robust environmental protection and improved structural integrity, effectively shielding electronics from moisture, dust, and physical damage in harsh conditions. Choosing underfill improves performance in precision microelectronics, while overmold delivers durability and longevity for ruggedized devices.

Cost Considerations for Underfill and Overmold

Underfill typically incurs lower material costs but may require precise application techniques and additional curing time, impacting overall production expenses. Overmold involves higher upfront tooling and material costs due to complex mold design and larger resin volumes, yet it offers enhanced mechanical protection and durability. Choosing between underfill and overmold depends on balancing budget constraints with performance requirements in electronics packaging.

Reliability and Durability Comparisons

Underfill materials enhance reliability by providing superior protection against thermal cycling and mechanical stress in electronic assemblies, minimizing solder joint fatigue. Overmolding offers robust durability through encapsulating components in a protective polymer that shields against moisture, dust, and physical impact. Your choice depends on whether improving joint stress resistance (underfill) or full-component environmental protection (overmold) is more critical for the application.

Design Flexibility and Limitations

Underfill offers limited design flexibility as it primarily strengthens and protects solder joints in compact electronic assemblies, ensuring enhanced mechanical reliability with minimal alteration to component layout. Overmold provides greater design versatility by encapsulating entire electronic components or assemblies, enabling complex shapes, improved environmental protection, and customization of physical properties such as thermal resistance and shock absorption. Your choice between underfill and overmold depends on specific design requirements, balancing structural support and adaptability to varying product geometries.

Choosing the Right Solution: Underfill or Overmold

Choosing the right solution between underfill and overmold depends on your application's mechanical protection and thermal management needs. Underfill offers enhanced stress resistance and reliability for delicate electronics by filling gaps between components and substrates, while overmold provides robust environmental protection through full encapsulation of parts. Evaluating factors like impact resistance, moisture protection, and production complexity ensures your electronics receive optimal durability and performance.

Underfill vs Overmold Infographic

libmatt.com

libmatt.com