Mask aligners provide precise layer-to-layer alignment suitable for lower volume or research-grade semiconductor fabrication, while steppers offer high-resolution, automated patterning ideal for mass production with complex, densely packed circuits. Your choice depends on the required throughput, feature size, and alignment accuracy for your specific lithography process.

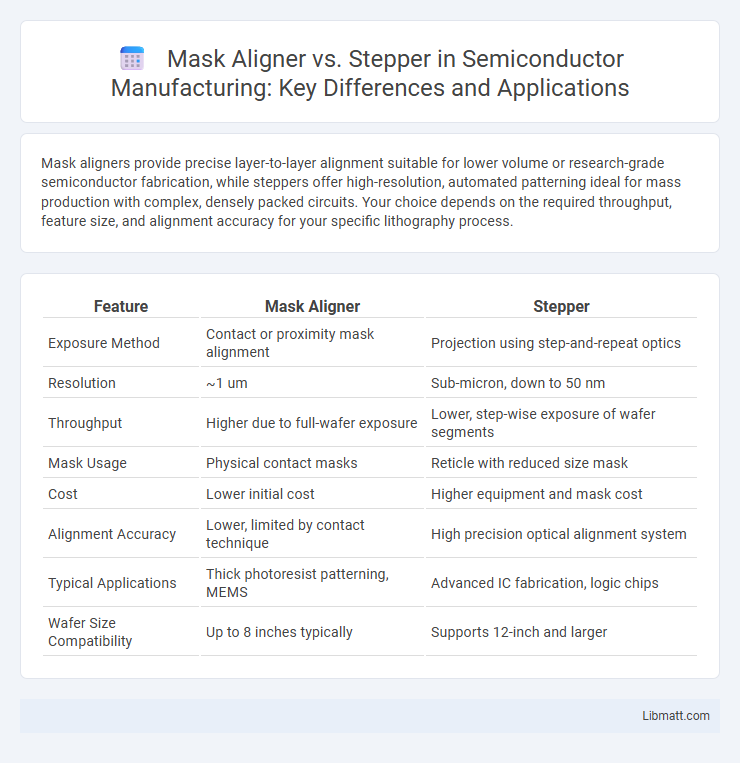

Table of Comparison

| Feature | Mask Aligner | Stepper |

|---|---|---|

| Exposure Method | Contact or proximity mask alignment | Projection using step-and-repeat optics |

| Resolution | ~1 um | Sub-micron, down to 50 nm |

| Throughput | Higher due to full-wafer exposure | Lower, step-wise exposure of wafer segments |

| Mask Usage | Physical contact masks | Reticle with reduced size mask |

| Cost | Lower initial cost | Higher equipment and mask cost |

| Alignment Accuracy | Lower, limited by contact technique | High precision optical alignment system |

| Typical Applications | Thick photoresist patterning, MEMS | Advanced IC fabrication, logic chips |

| Wafer Size Compatibility | Up to 8 inches typically | Supports 12-inch and larger |

Introduction to Lithography: Mask Aligner vs Stepper

Mask aligners and steppers are essential lithography tools used in semiconductor fabrication to transfer circuit patterns onto wafers. Mask aligners utilize contact or proximity printing methods, offering lower cost and high throughput for larger feature sizes, while steppers employ projection lithography with advanced optics to achieve higher resolution and alignment precision for smaller node technologies. Your choice between a mask aligner and a stepper depends on the specific resolution requirements, wafer volume, and budget constraints of your semiconductor manufacturing process.

What is a Mask Aligner?

A Mask Aligner is a precise lithography tool used in semiconductor manufacturing to align photomasks with wafers for pattern transfer during photolithography. It offers high accuracy in overlay alignment, essential for multi-layer device fabrication, making it suitable for research and small-scale production. Your choice between a Mask Aligner and a Stepper depends on the required alignment precision, throughput, and feature size for your specific application.

What is a Stepper?

A stepper is a photolithography tool used in semiconductor manufacturing that projects a reduced image of a photomask onto a wafer with high precision, enabling finer pattern resolution and alignment accuracy compared to mask aligners. Unlike mask aligners that expose the entire wafer at once, steppers expose small sections sequentially, which allows for more detailed and complex circuit fabrication. This technology is essential for producing modern integrated circuits with smaller feature sizes and enhanced performance.

Key Differences Between Mask Aligner and Stepper

Mask aligners enable rapid photolithography with contact or proximity exposure, offering simplicity and lower cost suitable for large, flat substrates. Steppers utilize projection optics to achieve high-resolution patterning by sequentially exposing small fields, enabling advanced integrated circuit fabrication with superior alignment accuracy and feature detail. Key differences include resolution capability, throughput efficiency, and adaptability to complex semiconductor designs.

Advantages of Mask Aligners

Mask aligners provide superior alignment accuracy for photolithography processes, enabling precise pattern transfer crucial for microfabrication. They offer cost-effective operation and maintenance compared to steppers, making them ideal for prototype development and small-batch production. Their compatibility with a wide range of photoresist materials enhances versatility in semiconductor manufacturing and MEMS device fabrication.

Advantages of Steppers

Steppers offer superior resolution and alignment accuracy compared to mask aligners, enabling finer feature patterning essential for advanced semiconductor manufacturing. You benefit from increased throughput and scalability due to their ability to perform wafer-by-wafer exposure with automated alignment and overlay control. These advantages make steppers ideal for producing high-density integrated circuits with tight process tolerances.

Typical Applications: Mask Aligner vs Stepper

Mask aligners are commonly used for low to medium volume semiconductor manufacturing, photolithography in MEMS fabrication, and research labs due to their cost-effectiveness and ease of use. Steppers excel in high-volume production of integrated circuits, advanced semiconductor devices, and applications requiring high resolution and alignment precision. Your choice depends on throughput requirements and feature size, with steppers preferred for complex, high-density patterns and mask aligners suited for simpler, larger-scale features.

Resolution and Precision: Performance Comparison

Mask aligners typically achieve resolution limits around 1 micron, suitable for large-area patterning with moderate precision, while steppers offer higher resolution down to 100 nanometers, enabling finer feature definition and superior overlay accuracy. Steppers utilize projection optics and step-and-repeat mechanisms to enhance precision, making them ideal for advanced semiconductor manufacturing requiring tight alignment tolerances. The superior resolution and precision of steppers result in more intricate circuit patterns compared to mask aligners, which are better suited for less demanding lithography tasks.

Cost Analysis: Mask Aligner vs Stepper

Mask aligners offer a significantly lower upfront cost compared to steppers, making them ideal for small-scale or research applications where budget constraints are critical. Steppers, however, involve higher initial investment and maintenance expenses but provide superior resolution and throughput, justifying the cost in high-volume semiconductor manufacturing. Your choice depends on balancing cost efficiency with precision requirements in your photolithography process.

Choosing the Right Tool for Your Lithography Needs

Selecting between a mask aligner and a stepper depends on resolution requirements and production volume; mask aligners offer cost-effective solutions for lower-resolution tasks typically above 1 micron, while steppers excel in high-resolution lithography below 1 micron with precise overlay control. Consider process throughput and feature size, as steppers provide superior alignment accuracy essential for advanced semiconductor fabrication, though mask aligners are favored for rapid prototyping and less complex patterning. Evaluating specific application demands, budget constraints, and desired yield ensures optimal tool selection tailored to your lithography needs.

Mask Aligner vs Stepper Infographic

libmatt.com

libmatt.com