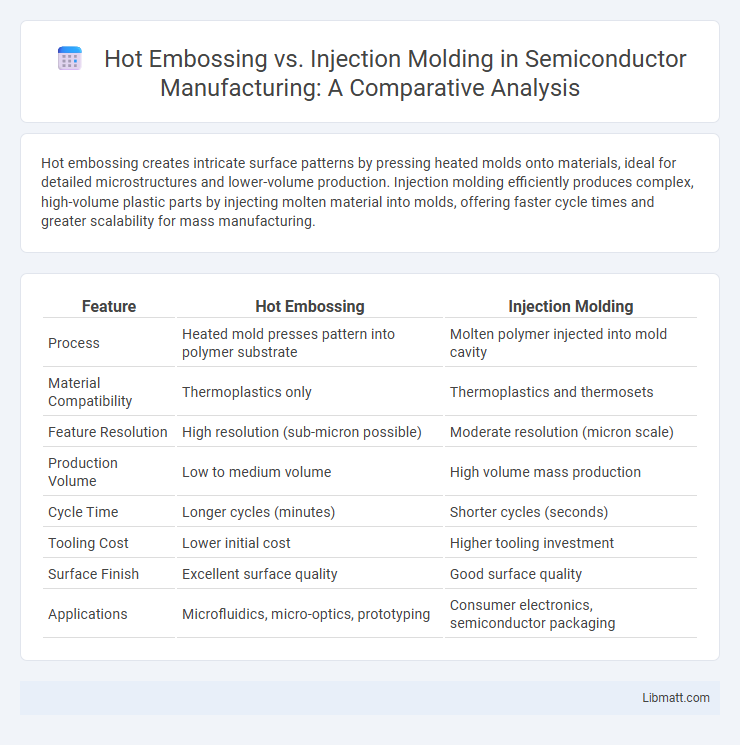

Hot embossing creates intricate surface patterns by pressing heated molds onto materials, ideal for detailed microstructures and lower-volume production. Injection molding efficiently produces complex, high-volume plastic parts by injecting molten material into molds, offering faster cycle times and greater scalability for mass manufacturing.

Table of Comparison

| Feature | Hot Embossing | Injection Molding |

|---|---|---|

| Process | Heated mold presses pattern into polymer substrate | Molten polymer injected into mold cavity |

| Material Compatibility | Thermoplastics only | Thermoplastics and thermosets |

| Feature Resolution | High resolution (sub-micron possible) | Moderate resolution (micron scale) |

| Production Volume | Low to medium volume | High volume mass production |

| Cycle Time | Longer cycles (minutes) | Shorter cycles (seconds) |

| Tooling Cost | Lower initial cost | Higher tooling investment |

| Surface Finish | Excellent surface quality | Good surface quality |

| Applications | Microfluidics, micro-optics, prototyping | Consumer electronics, semiconductor packaging |

Introduction to Hot Embossing and Injection Molding

Hot embossing is a precision microfabrication technique that uses heated molds to imprint micro-scale patterns onto thermoplastic substrates, enabling highly detailed surface structures often used in microfluidics and optical devices. Injection molding involves injecting molten plastic into a mold cavity, rapidly cooling and solidifying to produce large volumes of complex, durable parts with tight tolerances and consistent quality. Understanding the operational differences between hot embossing and injection molding is essential for selecting the appropriate method based on factors like production volume, feature resolution, and material properties.

Overview of Manufacturing Processes

Hot embossing involves imprinting micro- or nanostructures onto thermoplastic substrates by applying heat and pressure using a patterned mold, making it ideal for producing detailed surface features with high precision. Injection molding melts plastic pellets and injects the molten material into a mold cavity, producing complex, high-volume parts with rapid cycle times and consistent repeatability. Both processes serve distinct manufacturing needs: hot embossing excels in fine microfabrication for applications like microfluidics, while injection molding is preferred for mass production of durable plastic components.

Key Differences in Material Compatibility

Hot embossing primarily supports thermoplastic polymers such as PMMA, PC, and PS, allowing fine micro- and nano-scale patterning with minimal material stress. Injection molding accommodates a broader range of thermoplastics and thermosets, including ABS, PP, and polycarbonate, enabling complex, three-dimensional part production but may introduce residual stresses due to high pressure and temperature. Material compatibility in hot embossing favors precision in small-batch or prototype applications, while injection molding excels in high-volume manufacturing with diverse polymer options.

Precision and Surface Quality Comparison

Hot embossing delivers superior surface quality with high fidelity replication of micro- and nano-scale features due to direct imprinting, resulting in smooth textures and fine details. Injection molding offers excellent precision in complex geometries but may face limitations with extremely fine surface finishes and microstructural accuracy caused by polymer flow and cooling variances. The choice depends on required feature resolution, with hot embossing excelling in high-precision micro-scale applications while injection molding suits mass production of intricate parts with good dimensional accuracy.

Cost Analysis: Tooling and Production

Hot embossing offers lower initial tooling costs compared to injection molding, which requires expensive molds made from hardened steel. Production costs for hot embossing remain competitive for small to medium batch sizes due to faster mold fabrication and less energy consumption. Injection molding becomes more cost-effective at high volumes as economies of scale reduce per-unit expenses despite its higher upfront investment.

Cycle Time and Production Speed

Hot embossing typically features shorter cycle times ranging from seconds to a few minutes, enabling faster production speeds for small to medium batch sizes. Injection molding offers high production rates with cycle times often under a minute, making it ideal for mass production of complex parts. The choice between hot embossing and injection molding largely depends on the required volume and precision, as injection molding scales better for large volumes while hot embossing suits rapid prototyping.

Design Flexibility and Limitations

Hot embossing offers superior design flexibility for micro- and nano-scale features, enabling intricate surface patterns with high precision, which injection molding may struggle to replicate due to mold complexity and tooling costs. Injection molding excels in producing high-volume parts with consistent geometries but faces limitations in micro-detail resolution and rapid prototyping due to longer mold fabrication times. Your choice depends on whether fine surface detail or mass production efficiency is the priority in your manufacturing process.

Typical Applications in Industry

Hot embossing is widely used in microfluidics and flexible electronics manufacturing due to its precision in replicating micro- and nano-scale patterns on polymer substrates. Injection molding dominates in mass production of complex plastic parts for automotive, consumer goods, and medical devices, offering high throughput and consistent quality. Industries favor hot embossing for small batch, high-detail applications while injection molding suits large volume, structurally demanding components.

Environmental Impact and Sustainability

Hot embossing uses less energy and generates less waste compared to injection molding, making it a more environmentally sustainable choice for small-scale or prototype production. Injection molding often requires high temperatures and pressures, leading to greater carbon emissions and higher material consumption. Your decision between these methods can significantly affect the overall environmental footprint of your manufacturing process.

Choosing the Right Process for Your Project

Hot embossing offers precise micro- and nano-scale patterning suitable for small batch production and prototyping, while injection molding excels in high-volume manufacturing with excellent repeatability and complex geometries. Consider material compatibility, production volume, and cost-effectiveness; hot embossing is ideal for polymers sensitive to high temperatures, whereas injection molding suits thermoplastics demanding rapid cycle times. Selecting the right process hinges on balancing design complexity, surface detail requirements, and budget constraints to optimize functionality and scalability.

Hot Embossing vs Injection Molding Infographic

libmatt.com

libmatt.com