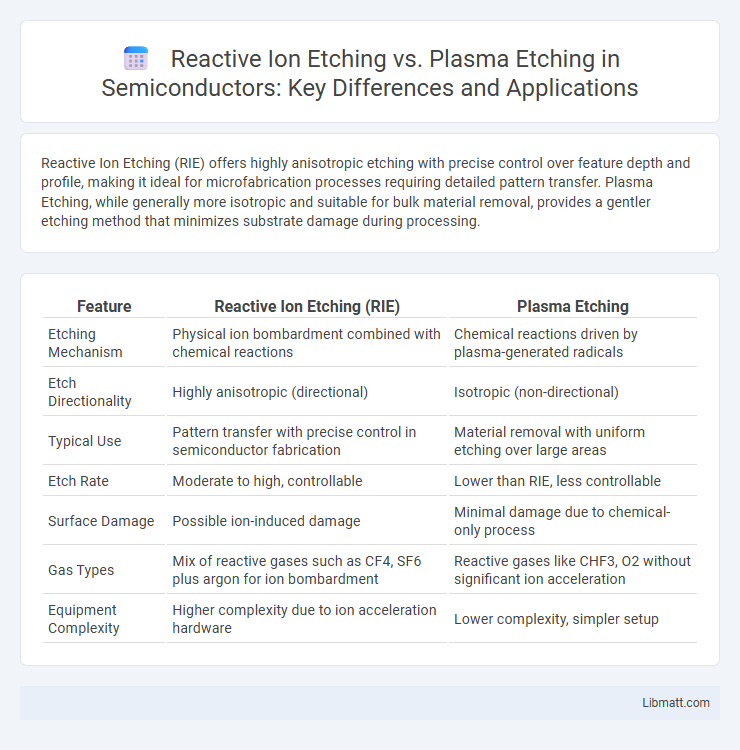

Reactive Ion Etching (RIE) offers highly anisotropic etching with precise control over feature depth and profile, making it ideal for microfabrication processes requiring detailed pattern transfer. Plasma Etching, while generally more isotropic and suitable for bulk material removal, provides a gentler etching method that minimizes substrate damage during processing.

Table of Comparison

| Feature | Reactive Ion Etching (RIE) | Plasma Etching |

|---|---|---|

| Etching Mechanism | Physical ion bombardment combined with chemical reactions | Chemical reactions driven by plasma-generated radicals |

| Etch Directionality | Highly anisotropic (directional) | Isotropic (non-directional) |

| Typical Use | Pattern transfer with precise control in semiconductor fabrication | Material removal with uniform etching over large areas |

| Etch Rate | Moderate to high, controllable | Lower than RIE, less controllable |

| Surface Damage | Possible ion-induced damage | Minimal damage due to chemical-only process |

| Gas Types | Mix of reactive gases such as CF4, SF6 plus argon for ion bombardment | Reactive gases like CHF3, O2 without significant ion acceleration |

| Equipment Complexity | Higher complexity due to ion acceleration hardware | Lower complexity, simpler setup |

Introduction to Reactive Ion Etching and Plasma Etching

Reactive Ion Etching (RIE) utilizes chemically reactive plasma ions combined with physical ion bombardment to achieve highly anisotropic and precise material removal, making it ideal for microfabrication and semiconductor processes. Plasma Etching, by contrast, primarily relies on chemically reactive neutral species in plasma to isotropically etch materials, often used for surface cleaning and bulk material removal. Your choice between RIE and plasma etching depends on the required etch profile control and material selectivity for your application.

Fundamental Principles of Each Etching Technique

Reactive Ion Etching (RIE) utilizes chemically reactive ions generated in a plasma to precisely remove material through a combination of physical sputtering and chemical reactions, offering anisotropic etching profiles essential for semiconductor fabrication. Plasma Etching primarily relies on chemically reactive neutral species and radicals within the plasma to etch materials isotropically by breaking chemical bonds at the surface. The fundamental difference lies in RIE's directional ion bombardment enhancing etch anisotropy, whereas plasma etching emphasizes purely chemical interactions for more uniform, non-directional material removal.

Equipment and Process Configuration

Reactive Ion Etching (RIE) utilizes a parallel plate reactor with RF power applied to the substrate, generating anisotropic etching through directional ion bombardment. Plasma Etching typically employs a capacitively coupled or inductively coupled plasma source to produce a chemically reactive plasma, emphasizing isotropic etch profiles driven primarily by neutral radicals. Equipment differences highlight RIE's need for precise RF bias control and vacuum chambers optimized for ion acceleration, whereas plasma etching systems focus on uniform plasma generation and gas flow management for consistent chemical etching.

Mechanisms of Material Removal

Reactive Ion Etching (RIE) removes material through a combination of physical sputtering by high-energy ions and chemical reactions between reactive species and the substrate, resulting in anisotropic etching profiles. Plasma Etching primarily relies on chemically reactive species generated in the plasma to selectively react with and volatilize the substrate material, typically producing isotropic etching. The key distinction lies in RIE's use of directional ion bombardment to enhance etch precision and anisotropy, whereas Plasma Etching emphasizes purely chemical mechanisms for material removal.

Process Parameters and Control Variables

Reactive Ion Etching (RIE) utilizes a combination of chemical reactions and physical ion bombardment, with process parameters such as RF power, gas flow rates, pressure, and substrate temperature critically controlled to optimize anisotropy and etch selectivity. Plasma Etching, primarily chemical, depends on gas composition, pressure, and plasma density, with control variables adjusted to achieve desired etch rates and uniformity. Precise manipulation of ion energy and reactive species concentration in RIE allows for finer pattern resolution compared to the more isotropic plasma etching process.

Etching Selectivity and Precision

Reactive Ion Etching (RIE) offers superior etching selectivity and precision compared to traditional Plasma Etching due to its anisotropic ion bombardment combined with chemical reactions. RIE enables precise pattern transfer with minimal lateral etching, crucial for high-resolution microfabrication in semiconductor device production. Plasma Etching, while effective for isotropic etching, generally exhibits lower selectivity and less directional control, making it less suitable for applications requiring fine feature definition.

Surface Damage and Profile Quality

Reactive Ion Etching (RIE) offers superior control over etch profiles, resulting in highly anisotropic features with minimal undercutting, which is crucial for precise microfabrication. Plasma Etching, being largely isotropic, tends to cause more surface damage and less defined feature edges due to its less directional ion bombardment. The physical ion impact in RIE enhances profile quality but can induce slight surface damage, whereas plasma etching's chemical dominance reduces damage but sacrifices edge precision.

Applications in Semiconductor Fabrication

Reactive Ion Etching (RIE) provides highly anisotropic etching ideal for precise pattern transfer in semiconductor fabrication, especially in defining fine features on silicon wafers and advanced integrated circuits. Plasma Etching, while typically more isotropic, excels in removing photoresist layers and blanket etching applications where uniform material removal is crucial. Both techniques are essential in microfabrication, with RIE preferred for high-resolution etching and Plasma Etching commonly used for large-area or less feature-critical processes.

Advantages and Limitations Comparison

Reactive Ion Etching (RIE) offers superior anisotropic etching capabilities with high precision, ideal for microfabrication of intricate patterns, while plasma etching generally provides more isotropic etching, suitable for bulk material removal. RIE's ion bombardment enhances etch rate and directional control but can cause surface damage or mask erosion, whereas plasma etching is gentler with less substrate damage but limited in achieving high aspect ratio features. Selecting between RIE and plasma etching depends on the required etch profile, material selectivity, and process complexity in semiconductor manufacturing and MEMS fabrication.

Future Trends in Dry Etching Technologies

Future trends in dry etching technologies emphasize enhanced precision and selectivity, with Reactive Ion Etching (RIE) evolving to support atomic-level accuracy using advanced plasma sources and tailored chemistry. Plasma Etching developments focus on low-damage, high-throughput processes by integrating remote plasma generation and real-time process monitoring systems. Your semiconductor manufacturing can benefit from these innovations, enabling finer patterning and improved material compatibility for next-generation devices.

Reactive Ion Etching vs Plasma Etching Infographic

libmatt.com

libmatt.com