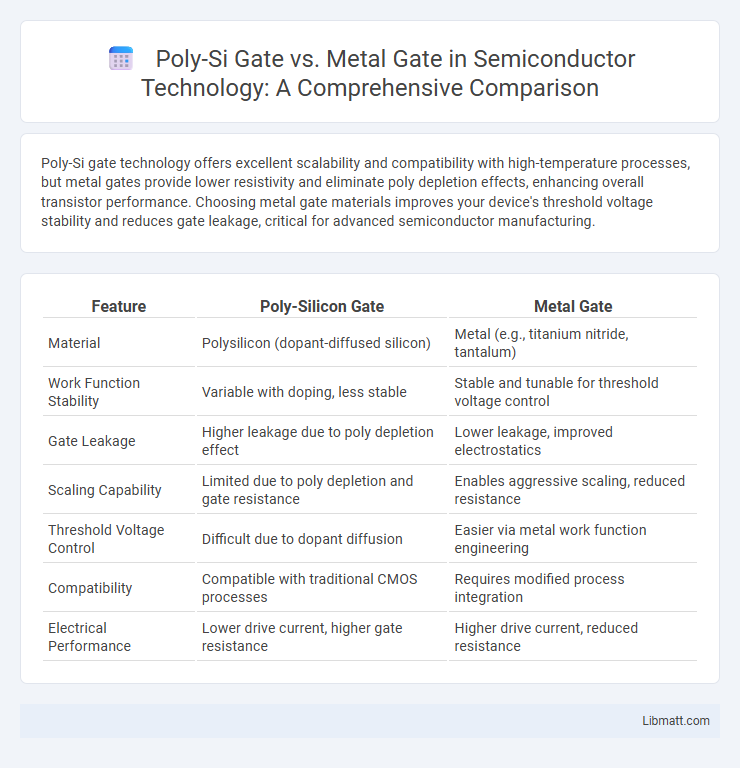

Poly-Si gate technology offers excellent scalability and compatibility with high-temperature processes, but metal gates provide lower resistivity and eliminate poly depletion effects, enhancing overall transistor performance. Choosing metal gate materials improves your device's threshold voltage stability and reduces gate leakage, critical for advanced semiconductor manufacturing.

Table of Comparison

| Feature | Poly-Silicon Gate | Metal Gate |

|---|---|---|

| Material | Polysilicon (dopant-diffused silicon) | Metal (e.g., titanium nitride, tantalum) |

| Work Function Stability | Variable with doping, less stable | Stable and tunable for threshold voltage control |

| Gate Leakage | Higher leakage due to poly depletion effect | Lower leakage, improved electrostatics |

| Scaling Capability | Limited due to poly depletion and gate resistance | Enables aggressive scaling, reduced resistance |

| Threshold Voltage Control | Difficult due to dopant diffusion | Easier via metal work function engineering |

| Compatibility | Compatible with traditional CMOS processes | Requires modified process integration |

| Electrical Performance | Lower drive current, higher gate resistance | Higher drive current, reduced resistance |

Introduction to Poly-Si Gate and Metal Gate Technologies

Poly-Silicon (Poly-Si) gates, popular in MOSFET fabrication, offer compatibility with high-temperature processes and established manufacturing techniques. Metal gate technologies, using materials like titanium nitride or tantalum, improve performance by reducing gate depletion and enabling lower power consumption at advanced technology nodes. Your choice between Poly-Si and metal gate impacts device scaling, threshold voltage control, and overall semiconductor efficiency.

Historical Evolution of Gate Materials in Semiconductors

The historical evolution of gate materials in semiconductors highlights the transition from polysilicon (Poly-Si) gates to metal gates driven by scaling challenges and performance demands. Poly-Si gates dominated early CMOS technology due to their compatibility with silicon processing, but issues like polysilicon depletion and gate resistance emerged as feature sizes shrank below 90 nm. The introduction of metal gates around the 45 nm technology node resolved these limitations by offering lower resistivity, enhanced work function tuning, and improved threshold voltage control, enabling continued device scaling and performance gains in modern semiconductor manufacturing.

Structural Differences: Poly-Si Gate vs Metal Gate

Poly-Si gates consist of doped polysilicon material, offering compatibility with silicon dioxide dielectrics but suffering from higher resistivity and polysilicon depletion effects. Metal gates, typically made from materials like titanium nitride or tantalum, provide lower resistivity and eliminate depletion, leading to improved drive current and faster switching speeds. Your choice between poly-Si and metal gate structures directly impacts transistor performance, threshold voltage control, and fabrication process complexity.

Electrical Performance Comparison

Metal gates offer superior electrical performance compared to poly-Si gates due to their lower gate resistance and elimination of poly depletion effect, resulting in faster switching speeds and improved drive current. The work function of metal gates can be precisely engineered to optimize threshold voltage, enhancing device scalability and reducing short-channel effects. Poly-Si gates suffer from higher gate leakage and slower electron mobility, which negatively impact transistor performance in advanced CMOS technologies.

Impact on Device Scaling and Miniaturization

Poly-Si gates face limitations in device scaling due to polysilicon depletion effects that increase gate resistance and reduce drive current as dimensions shrink below 45nm. Metal gates offer lower resistivity and better work function tuning, enabling improved threshold voltage control and reduced gate leakage, which are crucial for miniaturization beyond the 22nm technology node. Integrating metal gates with high-k dielectrics supports continued transistor scaling by minimizing short-channel effects and enhancing overall device performance.

Work Function Engineering: Poly-Si vs Metal Gate

Poly-Si gate electrodes exhibit limited work function tunability due to doping constraints, affecting threshold voltage control in advanced CMOS nodes. Metal gates offer precise work function engineering by selecting metals with tailored electronegativity, enabling improved device performance and scalability. This flexibility in metal gates enhances electrostatic control and reduces short-channel effects compared to poly-Si gates.

Influence on Threshold Voltage Control

Poly-Si gate technology offers inherent work function variability that affects threshold voltage control, often resulting in less precise tuning compared to metal gate counterparts. Metal gates provide improved threshold voltage stability due to their fixed work function, enhancing device performance in advanced CMOS technologies. Your choice between Poly-Si and metal gates directly impacts threshold voltage accuracy, influencing overall transistor behavior and power efficiency.

Manufacturing Process and Integration Challenges

Poly-Si gate technology involves depositing polysilicon on the gate oxide followed by doping and patterning, which integrates well with traditional CMOS processes but suffers from polysilicon depletion and gate resistance issues. Metal gate technology replaces polysilicon with metal electrodes, offering reduced gate resistance and better threshold voltage control but requires complex work-function tuning and compatibility adjustments during high-temperature manufacturing steps. Integrating metal gates demands advanced process innovations such as gate-last schemes and selective metal deposition to overcome challenges related to diffusion, stress, and interfaces in scaled device architectures.

Reliability and Long-Term Performance

Poly-Si gates demonstrate higher susceptibility to threshold voltage shifts over time due to charge trapping and grain boundary effects, impacting device reliability in advanced nodes. Metal gates offer superior long-term performance by minimizing gate depletion and reducing resistance, which enhances stability and reduces degradation under operational stress. Your choice between Poly-Si and metal gates significantly influences the reliability and lifespan of semiconductor devices, especially in high-performance and low-power applications.

Future Trends and Industry Adoption

Metal gate technology is rapidly replacing poly-Si gate in advanced semiconductor manufacturing due to superior electrical performance, reduced gate depletion effects, and better compatibility with high-k dielectrics. Leading chipmakers prioritize metal gates for sub-7nm process nodes, driving widespread industry adoption as devices demand enhanced speed and energy efficiency. Your choice between poly-Si and metal gates impacts device scaling potential and integration with future transistor architectures.

Poly-Si Gate vs Metal Gate Infographic

libmatt.com

libmatt.com