Low-k and ultra low-k dielectrics differ primarily in their dielectric constant values, with ultra low-k materials offering superior reduction in capacitance to enhance signal speed and reduce power consumption in semiconductor devices. Choosing ultra low-k dielectrics can significantly improve your chip performance and enable higher integration density in advanced electronics manufacturing.

Table of Comparison

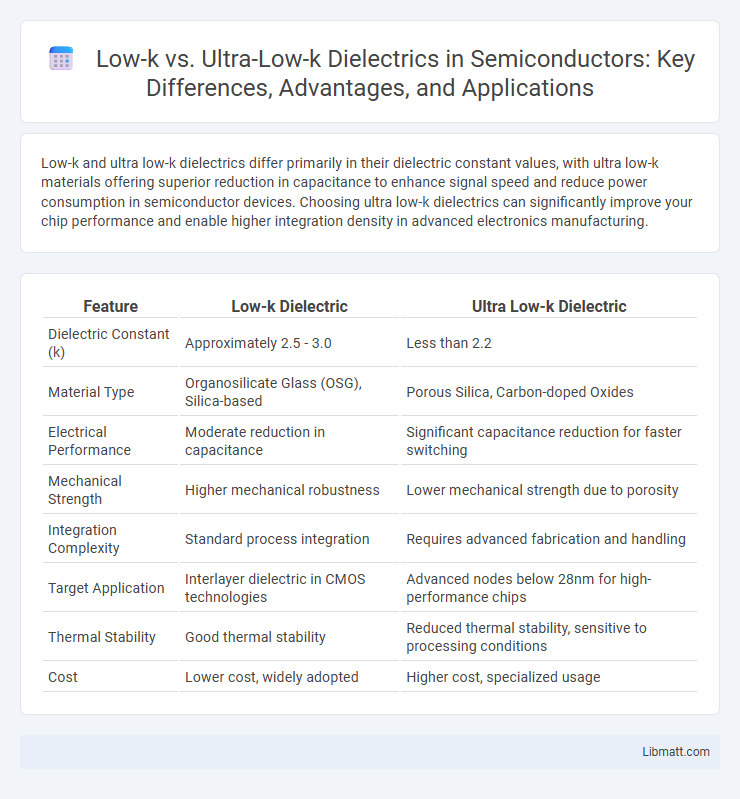

| Feature | Low-k Dielectric | Ultra Low-k Dielectric |

|---|---|---|

| Dielectric Constant (k) | Approximately 2.5 - 3.0 | Less than 2.2 |

| Material Type | Organosilicate Glass (OSG), Silica-based | Porous Silica, Carbon-doped Oxides |

| Electrical Performance | Moderate reduction in capacitance | Significant capacitance reduction for faster switching |

| Mechanical Strength | Higher mechanical robustness | Lower mechanical strength due to porosity |

| Integration Complexity | Standard process integration | Requires advanced fabrication and handling |

| Target Application | Interlayer dielectric in CMOS technologies | Advanced nodes below 28nm for high-performance chips |

| Thermal Stability | Good thermal stability | Reduced thermal stability, sensitive to processing conditions |

| Cost | Lower cost, widely adopted | Higher cost, specialized usage |

Introduction to Low-k and Ultra Low-k Dielectric Materials

Low-k and Ultra Low-k dielectric materials are essential for reducing capacitance in semiconductor devices, enhancing overall chip performance and power efficiency. Low-k dielectrics typically have a dielectric constant (k) below 3.0, while Ultra Low-k materials achieve values below 2.5, enabling even greater reduction in electronic signal delay. You can improve the speed and reliability of integrated circuits by selecting the appropriate dielectric material to minimize parasitic capacitance and cross-talk.

Importance of Dielectric Constants in Semiconductor Industry

Dielectric constants play a critical role in the semiconductor industry by directly affecting the performance and scaling of integrated circuits. Low-k dielectrics, with constant values typically between 2.5 and 3.0, reduce parasitic capacitance, thereby enhancing signal speed and reducing power consumption. Ultra Low-k dielectrics, with constants below 2.5, push these benefits further, enabling smaller feature sizes and higher device densities essential for advanced semiconductor manufacturing.

Material Composition: Low-k vs Ultra Low-k Dielectrics

Low-k dielectrics typically consist of silicon oxide-based materials infused with carbon or fluorine to reduce dielectric constant values to around 2.7-3.0, while ultra low-k dielectrics incorporate porous structures or organosilicate glasses to achieve dielectric constants below 2.5. The incorporation of porosity in ultra low-k materials significantly lowers the dielectric constant but introduces challenges such as reduced mechanical strength and increased susceptibility to moisture absorption. Advances in material composition for ultra low-k dielectrics focus on balancing porosity with mechanical stability by optimizing the organic-inorganic hybrid network and pore size distribution.

Electrical Performance Comparison

Low-k and Ultra Low-k dielectrics differ significantly in electrical performance; Ultra Low-k materials exhibit lower dielectric constants typically below 2.5, which reduces parasitic capacitance and enhances signal speed in integrated circuits. Ultra Low-k dielectrics minimize RC delay and power consumption more effectively than conventional Low-k dielectrics, which usually have dielectric constants around 2.9 to 3.0. However, Ultra Low-k materials often require advanced fabrication techniques to maintain mechanical stability while optimizing electrical insulating properties.

Impact on Interconnect Capacitance

Low-k and Ultra Low-k dielectrics significantly reduce interconnect capacitance by lowering the dielectric constant in semiconductor devices, enhancing signal speed and reducing power consumption. Ultra Low-k materials have a dielectric constant typically below 2.5, compared to Low-k materials which range from 2.5 to 3.0, offering superior capacitance reduction and improved overall device performance. Your choice between Low-k and Ultra Low-k will affect interconnect delay and cross-talk, critical factors in advanced integrated circuit design.

Integration Challenges and Process Compatibility

Low-k dielectrics offer moderate reduction in dielectric constant but face fewer integration challenges compared to Ultra Low-k materials, which struggle with brittleness and reduced mechanical strength affecting process compatibility. Ultra Low-k dielectrics require advanced deposition techniques and careful pore sealing to maintain integrity during integration with copper metallization and chemical-mechanical polishing (CMP). Process compatibility issues for Ultra Low-k include sensitivity to plasma damage and moisture absorption, necessitating specialized protective treatments and optimized etch chemistries to ensure device reliability.

Mechanical Strength and Reliability

Low-k dielectrics generally offer moderate mechanical strength suitable for standard semiconductor applications, while ultra low-k dielectrics exhibit significantly lower mechanical strength, increasing vulnerability to cracking and mechanical failure. The reduced density and increased porosity in ultra low-k materials enhance performance but compromise reliability under thermal and mechanical stress. Mitigating these challenges involves advanced integration techniques and material reinforcement to maintain device longevity.

Cost and Manufacturing Considerations

Low-k dielectrics typically offer a balanced cost-to-performance ratio, utilizing well-established manufacturing processes that reduce production complexity and expenses. Ultra low-k dielectrics, while providing superior electrical performance and reduced signal delay, often incur higher material and process costs due to advanced deposition techniques and strict integration challenges. Cost-efficient integration of ultra low-k materials demands sophisticated equipment and rigorous quality control, impacting overall manufacturing throughput and yield.

Future Trends in Dielectric Materials

Future trends in dielectric materials emphasize the shift from traditional Low-k to Ultra Low-k dielectrics, driven by the need for improved performance in advanced semiconductor devices. Ultra Low-k dielectrics offer significantly lower dielectric constants below 2.5, reducing parasitic capacitance and enhancing signal speed and power efficiency in next-generation integrated circuits. You can expect ongoing research to focus on improving the mechanical stability and integration compatibility of Ultra Low-k materials, enabling further miniaturization and higher transistor densities in future chip designs.

Conclusion: Choosing the Right Dielectric for Advanced Nodes

Ultra low-k dielectrics offer significantly lower dielectric constants (k < 2.5) compared to low-k materials (k 2.5 to 3.0), reducing capacitance and signal delay in advanced semiconductor nodes. Your selection depends on trade-offs between mechanical strength, integration complexity, and electrical performance in sub-10nm technologies. For the most advanced nodes, ultra low-k dielectrics enhance device speed and power efficiency but require careful consideration of process compatibility and reliability challenges.

Low-k vs Ultra Low-k Dielectric Infographic

libmatt.com

libmatt.com