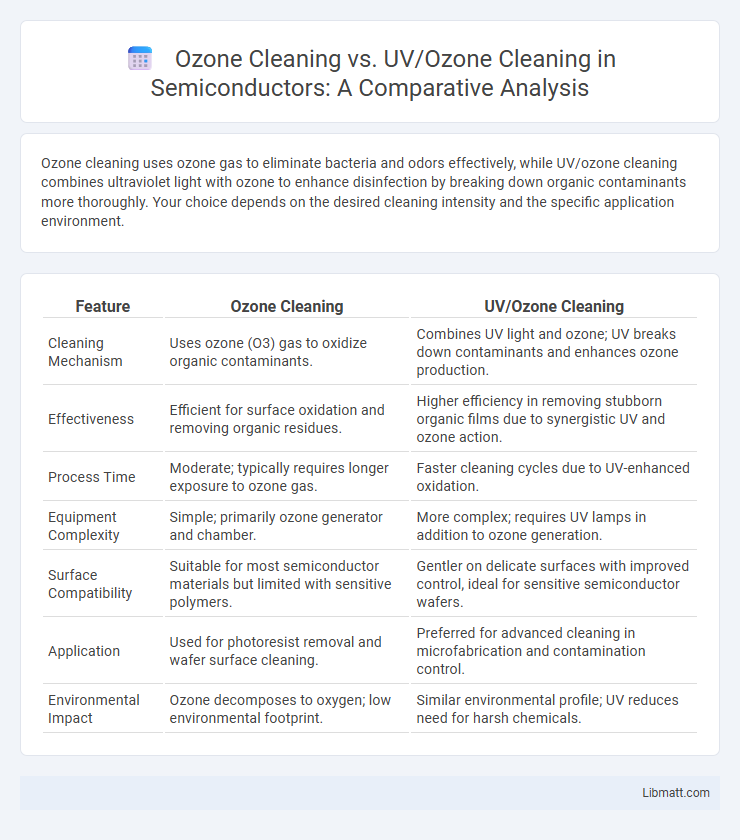

Ozone cleaning uses ozone gas to eliminate bacteria and odors effectively, while UV/ozone cleaning combines ultraviolet light with ozone to enhance disinfection by breaking down organic contaminants more thoroughly. Your choice depends on the desired cleaning intensity and the specific application environment.

Table of Comparison

| Feature | Ozone Cleaning | UV/Ozone Cleaning |

|---|---|---|

| Cleaning Mechanism | Uses ozone (O3) gas to oxidize organic contaminants. | Combines UV light and ozone; UV breaks down contaminants and enhances ozone production. |

| Effectiveness | Efficient for surface oxidation and removing organic residues. | Higher efficiency in removing stubborn organic films due to synergistic UV and ozone action. |

| Process Time | Moderate; typically requires longer exposure to ozone gas. | Faster cleaning cycles due to UV-enhanced oxidation. |

| Equipment Complexity | Simple; primarily ozone generator and chamber. | More complex; requires UV lamps in addition to ozone generation. |

| Surface Compatibility | Suitable for most semiconductor materials but limited with sensitive polymers. | Gentler on delicate surfaces with improved control, ideal for sensitive semiconductor wafers. |

| Application | Used for photoresist removal and wafer surface cleaning. | Preferred for advanced cleaning in microfabrication and contamination control. |

| Environmental Impact | Ozone decomposes to oxygen; low environmental footprint. | Similar environmental profile; UV reduces need for harsh chemicals. |

Introduction to Ozone and UV/Ozone Cleaning

Ozone cleaning utilizes ozone gas (O3) as a powerful oxidizing agent to eliminate contaminants, odors, and microorganisms from surfaces and air. UV/ozone cleaning combines ultraviolet (UV) light with ozone generation, where UV light produces ozone and breaks down organic compounds more efficiently. This hybrid approach enhances the cleaning and sterilization process by leveraging both UV radiation and ozone's oxidative properties for thorough decontamination.

How Ozone Cleaning Works

Ozone cleaning works by generating ozone gas (O3), a powerful oxidizing agent that breaks down organic contaminants and disinfects surfaces by destroying bacteria, viruses, and odors at the molecular level. UV/ozone cleaning combines ultraviolet light with ozone generation, where UV light splits oxygen molecules to form ozone, enhancing the cleaning efficiency through photochemical reactions. Your choice between these methods depends on the need for faster microbial inactivation or targeting specific surface contaminants.

The Science Behind UV/Ozone Cleaning

UV/ozone cleaning combines ultraviolet light with ozone gas to effectively break down organic contaminants at a molecular level through photochemical reactions and oxidative processes. The UV light generates ozone from atmospheric oxygen, while high-energy UV photons disrupt molecular bonds, allowing ozone to oxidize and remove surface residues without abrasive methods. This synergy enhances cleaning efficiency for delicate materials, ensuring your surfaces are free from microscopic impurities that traditional ozone cleaning alone may not eliminate.

Key Differences Between Ozone and UV/Ozone Cleaning

Ozone cleaning relies solely on ozone gas generated electrically to oxidize and eliminate contaminants, while UV/ozone cleaning combines ultraviolet light with ozone production for enhanced surface oxidation and sterilization. The UV component breaks down ozone into reactive atomic oxygen, increasing cleaning efficiency, especially on organic residues and in hard-to-reach areas. Your choice depends on the application requirements, as UV/ozone cleaning typically offers faster and more thorough treatment compared to ozone cleaning alone.

Applications of Ozone Cleaning

Ozone cleaning is widely applied in water treatment, food processing, and pharmaceutical industries due to its strong oxidative properties that effectively eliminate contaminants and pathogens. UV/ozone cleaning enhances this process by combining ultraviolet light with ozone generation, making it ideal for semiconductor manufacturing, surface sterilization, and removing organic residues from delicate materials. You can choose ozone cleaning methods based on specific application needs, balancing factors such as surface compatibility, cleaning efficiency, and environmental impact.

Common Uses of UV/Ozone Cleaning

UV/ozone cleaning is commonly used in semiconductor manufacturing, medical device sterilization, and surface preparation for adhesive bonding due to its ability to effectively remove organic contaminants and sterilize surfaces. This method combines ultraviolet light and ozone generation to degrade complex organic materials, ensuring high levels of cleanliness without damaging sensitive substrates. Industries such as electronics, healthcare, and renewable energy rely on UV/ozone cleaning for precision cleaning tasks where traditional ozone cleaning may be insufficient.

Effectiveness Against Microorganisms and Contaminants

Ozone cleaning excels in breaking down organic contaminants and killing a wide range of bacteria, viruses, and fungi by oxidizing their cell walls, making it highly effective for general disinfection. UV/ozone cleaning combines the strong oxidizing power of ozone with germicidal ultraviolet light, enhancing microbial inactivation by disrupting DNA and RNA structures of microorganisms, resulting in superior sterilization performance. Studies show that UV/ozone cleaning systems achieve faster and more comprehensive decontamination compared to ozone cleaning alone, particularly in eliminating resistant pathogens and reducing volatile organic compounds (VOCs).

Safety Considerations and Precautions

Ozone cleaning involves generating ozone gas to remove contaminants but requires strict ventilation and exposure limits due to ozone's respiratory risks and potential skin irritation. UV/ozone cleaning combines ultraviolet light with ozone, enhancing disinfection effectiveness while necessitating protective measures against UV radiation and ozone inhalation. You should always ensure proper airflow and use protective equipment to minimize health hazards during either cleaning method.

Environmental Impact and Sustainability

Ozone cleaning generates reactive oxygen species that break down contaminants efficiently but can produce nitrogen oxides as byproducts, affecting air quality. UV/ozone cleaning enhances ozone generation using ultraviolet light, reducing chemical usage and minimizing waste, which supports sustainability goals with lower environmental pollution. Your choice between these methods impacts the ecological footprint, with UV/ozone cleaning generally offering a more environmentally friendly solution due to its reduced emissions and energy consumption.

Choosing the Right Cleaning Method for Your Needs

Ozone cleaning effectively eliminates odors and mold through oxidation, making it ideal for water and air purification, while UV/ozone cleaning combines ultraviolet light with ozone to target a broader spectrum of pathogens, including bacteria and viruses. Your choice depends on the specific contaminants, with UV/ozone cleaning offering enhanced disinfection for healthcare or food industries, whereas ozone cleaning suffices for general odor and mold removal. Evaluating the environmental conditions and safety requirements ensures selecting the right method tailored to your cleaning needs.

Ozone Cleaning vs UV/Ozone Cleaning Infographic

libmatt.com

libmatt.com