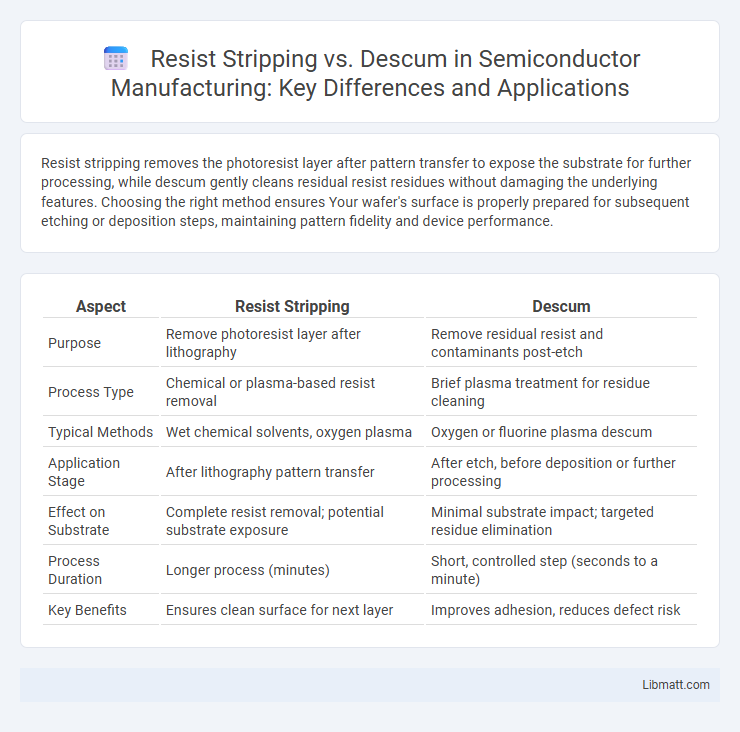

Resist stripping removes the photoresist layer after pattern transfer to expose the substrate for further processing, while descum gently cleans residual resist residues without damaging the underlying features. Choosing the right method ensures Your wafer's surface is properly prepared for subsequent etching or deposition steps, maintaining pattern fidelity and device performance.

Table of Comparison

| Aspect | Resist Stripping | Descum |

|---|---|---|

| Purpose | Remove photoresist layer after lithography | Remove residual resist and contaminants post-etch |

| Process Type | Chemical or plasma-based resist removal | Brief plasma treatment for residue cleaning |

| Typical Methods | Wet chemical solvents, oxygen plasma | Oxygen or fluorine plasma descum |

| Application Stage | After lithography pattern transfer | After etch, before deposition or further processing |

| Effect on Substrate | Complete resist removal; potential substrate exposure | Minimal substrate impact; targeted residue elimination |

| Process Duration | Longer process (minutes) | Short, controlled step (seconds to a minute) |

| Key Benefits | Ensures clean surface for next layer | Improves adhesion, reduces defect risk |

Introduction to Resist Stripping and Descum

Resist stripping and descum are critical processes in semiconductor fabrication used to remove unwanted photoresist materials after lithography. Resist stripping involves chemical or plasma-based techniques to completely eliminate the photoresist layer, ensuring clean wafer surfaces for subsequent processing steps. Descum, a milder plasma etch, targets residual resist residues or scum left after development, enhancing pattern fidelity without damaging underlying features.

Importance in Semiconductor Fabrication

Resist stripping removes the entire photoresist layer after patterning, ensuring clean surfaces for subsequent processing steps, while descum selectively removes residual resist in critical areas, enhancing pattern fidelity. Both processes are crucial in semiconductor fabrication to prevent defects and improve device performance by maintaining precise pattern transfers. Optimizing resist stripping and descum directly impacts your wafer quality and yield in advanced semiconductor manufacturing.

Definitions: What is Resist Stripping?

Resist stripping is the process of removing photoresist materials from a semiconductor wafer after lithography, ensuring a clean surface for subsequent fabrication steps. This step is critical to prevent contamination and maintain pattern integrity during etching or deposition. Your choice of resist stripping method impacts yield and overall device performance.

Definitions: What is Descum?

Descum is a plasma etching process used to remove residual photoresist or contaminants from a wafer surface after the development step but before etching or deposition. This gentle oxygen plasma treatment ensures clean, residue-free features without damaging the photoresist pattern. Resist stripping, by contrast, involves the complete removal of photoresist layers after pattern transfer processes.

Key Differences Between Resist Stripping and Descum

Resist stripping and descum are critical processes in semiconductor fabrication with distinct functions; resist stripping removes the photoresist layer entirely after pattern transfer, while descum eliminates residual organic materials, ensuring clean feature edges. Your choice between these processes affects wafer cleanliness and pattern fidelity, as resist stripping uses chemical solvents or plasma to remove bulk resist, whereas descum employs mild plasma treatment for fine residue removal. Understanding these key differences enhances process control, improving device performance and yield in microfabrication.

Common Methods for Resist Stripping

Common methods for resist stripping include wet chemical strippers using solvents like NMP (N-methyl-2-pyrrolidone) or alkaline solutions that effectively remove photoresist layers without damaging substrates. Plasma-based resist stripping employs oxygen or fluorine-containing gases to etch resist residues through reactive ion etching (RIE) or downstream plasma techniques. Thermal stripping uses high-temperature processes to break down resist polymers, often combined with gas flows to purge decomposed materials in semiconductor manufacturing.

Common Techniques for Descum Processes

Common techniques for descum processes include oxygen plasma etching, which effectively removes residual photoresist from substrate surfaces, and wet chemical descumming using solvents like sulfuric acid or developer solutions to clean fine features. Reactive ion etching (RIE) is another preferred method, utilizing ionized gases to ensure precision in clearing residues without damaging underlying layers. Your choice of descum technique depends on the substrate material and desired pattern fidelity, balancing efficiency with surface integrity.

Process Parameters: Temperature, Chemistry, and Time

Resist stripping and descum processes differ significantly in their process parameters, including temperature, chemistry, and time to achieve optimal results. Resist stripping often requires higher temperatures and aggressive chemical solvents such as N-Methyl-2-pyrrolidone (NMP) or hydroxylamine-based solutions to effectively remove photoresist films, typically taking several minutes. Descum, in contrast, uses low-temperature plasma or oxygen-based chemistries for a shorter duration, usually seconds to a minute, to gently remove residual resist without damaging underlying features, ensuring precise surface preparation for subsequent lithography steps.

Challenges and Solutions in Strip and Descum Steps

Resist stripping often faces challenges such as incomplete removal of photoresist residues and potential damage to underlying substrates, requiring optimized chemistries and controlled process conditions to ensure thorough cleaning without compromising device integrity. Descum steps demand precise etching to remove residual resist, with solutions including plasma recipes tailored to minimize substrate erosion and improve selectivity. Your success depends on balancing effective residue removal while protecting critical layers through carefully calibrated parameters in both resist strip and descum processes.

Recent Advances and Future Trends in Resist Stripping vs Descum

Recent advances in resist stripping techniques emphasize enhanced selectivity and reduced substrate damage using plasma and wet chemical methods, optimizing your semiconductor fabrication processes. Innovations in descum utilize low-power oxygen plasmas and cryogenic techniques to effectively remove residual resist while preserving delicate features. Future trends point toward eco-friendly, residue-free solutions combining advanced materials and AI-controlled process parameters for precision and sustainability in resist stripping versus descum.

Resist Stripping vs Descum Infographic

libmatt.com

libmatt.com