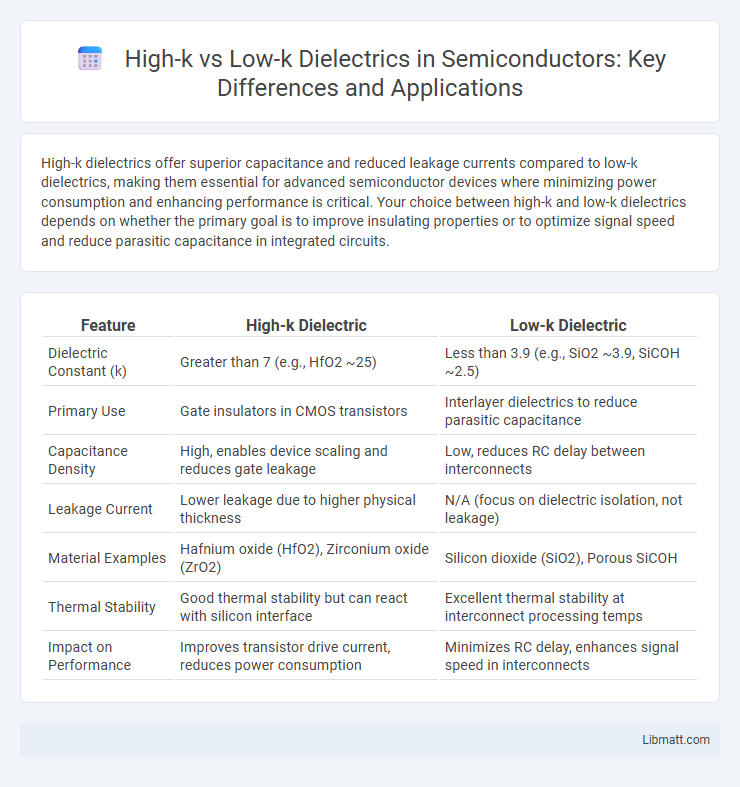

High-k dielectrics offer superior capacitance and reduced leakage currents compared to low-k dielectrics, making them essential for advanced semiconductor devices where minimizing power consumption and enhancing performance is critical. Your choice between high-k and low-k dielectrics depends on whether the primary goal is to improve insulating properties or to optimize signal speed and reduce parasitic capacitance in integrated circuits.

Table of Comparison

| Feature | High-k Dielectric | Low-k Dielectric |

|---|---|---|

| Dielectric Constant (k) | Greater than 7 (e.g., HfO2 ~25) | Less than 3.9 (e.g., SiO2 ~3.9, SiCOH ~2.5) |

| Primary Use | Gate insulators in CMOS transistors | Interlayer dielectrics to reduce parasitic capacitance |

| Capacitance Density | High, enables device scaling and reduces gate leakage | Low, reduces RC delay between interconnects |

| Leakage Current | Lower leakage due to higher physical thickness | N/A (focus on dielectric isolation, not leakage) |

| Material Examples | Hafnium oxide (HfO2), Zirconium oxide (ZrO2) | Silicon dioxide (SiO2), Porous SiCOH |

| Thermal Stability | Good thermal stability but can react with silicon interface | Excellent thermal stability at interconnect processing temps |

| Impact on Performance | Improves transistor drive current, reduces power consumption | Minimizes RC delay, enhances signal speed in interconnects |

Introduction to High-k and Low-k Dielectrics

High-k dielectrics feature a high dielectric constant, typically greater than 10, enabling superior capacitance and reduced leakage currents in semiconductor devices. Low-k dielectrics possess dielectric constants usually less than 3, aimed at minimizing parasitic capacitance and enhancing signal speed in interconnects. These materials are critical for optimizing performance and scaling in integrated circuits by balancing insulation properties and electrical efficiency.

Fundamental Concepts of Dielectric Materials

High-k dielectrics possess a high dielectric constant, enabling superior capacitance in semiconductor devices, which reduces leakage current and improves performance in miniaturized transistors. Low-k dielectrics exhibit low dielectric constants, essential for minimizing parasitic capacitance and signal delay in integrated circuits, particularly in interconnect layers. Understanding the trade-offs between dielectric constant, leakage current, and thermal stability is crucial for optimizing material selection in advanced microelectronics.

High-k Dielectrics: Definition and Key Properties

High-k dielectrics are materials with a high dielectric constant (k) typically greater than 10, used to increase gate capacitance while minimizing leakage current in semiconductor devices. Common high-k materials include hafnium oxide (HfO2), zirconium oxide (ZrO2), and aluminum oxide (Al2O3), known for their excellent thermal stability and compatibility with silicon substrates. These properties enable continued transistor scaling by reducing gate oxide thickness without increasing power consumption or compromising device reliability.

Low-k Dielectrics: Definition and Key Properties

Low-k dielectrics are materials characterized by a low dielectric constant, typically less than 3.9, used to reduce parasitic capacitance in integrated circuits, enhancing signal speed and reducing power consumption. Key properties include low permittivity, thermal stability, and compatibility with semiconductor manufacturing processes.

Material Choices for High-k and Low-k Dielectrics

High-k dielectrics commonly use materials like hafnium oxide (HfO2), zirconium oxide (ZrO2), and aluminum oxide (Al2O3) due to their high dielectric constants, which allow improved capacitance scaling in advanced semiconductor devices. Low-k dielectrics typically consist of porous silica, organosilicates, or fluorinated silica glass designed to reduce parasitic capacitance and signal delay in interconnects. Understanding these material choices helps you optimize device performance by balancing insulation quality and signal integrity.

Role in Semiconductor Device Scaling

High-k dielectrics enable continued semiconductor device scaling by reducing gate leakage current and allowing thinner equivalent oxide thickness without compromising capacitance. Low-k dielectrics play a critical role in minimizing interconnect capacitance, which reduces RC delay and power consumption in advanced integrated circuits. Optimizing the use of both high-k gate dielectrics and low-k interlayer dielectrics is essential for enhancing device performance and maintaining Moore's Law progression.

Electrical Performance Comparison: High-k vs Low-k

High-k dielectrics provide superior electrical performance by offering higher capacitance and reduced leakage current compared to low-k dielectrics, which are primarily designed to minimize parasitic capacitance and signal delay in interconnects. High-k materials, such as hafnium oxide, enable scaling of transistor gate dielectrics while maintaining gate control and reducing power consumption. Your choice between high-k and low-k dielectrics depends on whether enhancing gate performance or improving interconnect speed and reliability is the priority in your semiconductor device.

Reliability and Thermal Stability Issues

High-k dielectrics offer improved thermal stability and reliability in advanced semiconductor devices by reducing leakage current and enabling further device scaling, contrasting with low-k dielectrics, which often suffer from decreased mechanical strength and increased porosity leading to reliability challenges. Low-k materials tend to exhibit lower thermal stability, causing degradation under high-temperature processing, which compromises interconnect integrity and increases failure rates in integrated circuits. Choosing high-k dielectrics enhances your device's longevity and performance under thermal stress, making them preferable for cutting-edge applications requiring robust dielectric behavior.

Manufacturing Challenges and Integration

High-k dielectric materials face manufacturing challenges such as increased interface trap density and compatibility issues with existing silicon-based processes, requiring advanced deposition techniques like atomic layer deposition (ALD) for precise thickness control. Low-k dielectrics present integration difficulties including mechanical fragility and poor thermal stability, which complicate their use in back-end-of-line (BEOL) interconnects and demand careful process optimization to maintain dielectric integrity. Both types necessitate tailored fabrication strategies to balance performance benefits with manufacturability and scalability in semiconductor device production.

Future Trends in Dielectric Material Development

Future trends in dielectric material development emphasize enhancing capacitor performance and energy efficiency through high-k dielectrics, which offer greater capacitance and miniaturization potential. Research focuses on hybrid materials combining the stability of low-k dielectrics with the high permittivity of high-k materials to balance speed and power consumption. Your choice of dielectric material will significantly influence the scalability and reliability of next-generation semiconductor devices.

High-k Dielectric vs Low-k Dielectric Infographic

libmatt.com

libmatt.com