Scribe Line welding offers precise alignment by marking a consistent reference point, ensuring accuracy in heavy fabrication projects, while Saw Street cutting provides straight, clean edges ideal for structural components. Your choice depends on whether precision marking or clean cutting is more critical to your workflow efficiency.

Table of Comparison

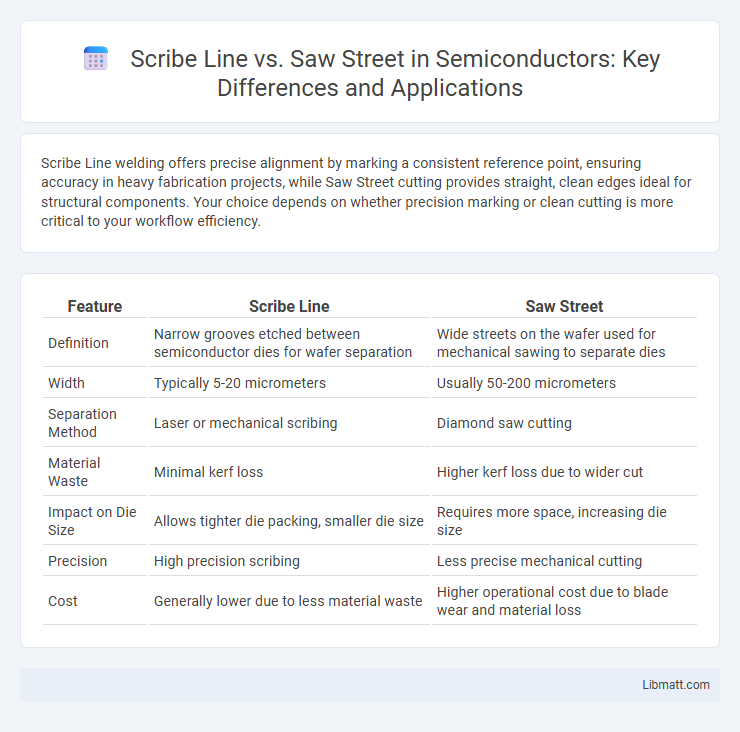

| Feature | Scribe Line | Saw Street |

|---|---|---|

| Definition | Narrow grooves etched between semiconductor dies for wafer separation | Wide streets on the wafer used for mechanical sawing to separate dies |

| Width | Typically 5-20 micrometers | Usually 50-200 micrometers |

| Separation Method | Laser or mechanical scribing | Diamond saw cutting |

| Material Waste | Minimal kerf loss | Higher kerf loss due to wider cut |

| Impact on Die Size | Allows tighter die packing, smaller die size | Requires more space, increasing die size |

| Precision | High precision scribing | Less precise mechanical cutting |

| Cost | Generally lower due to less material waste | Higher operational cost due to blade wear and material loss |

Understanding Scribe Line and Saw Street

Scribe line and saw street are critical terms in semiconductor wafer dicing, where the scribe line is the precise boundary marked on the wafer for cutting. Saw street refers to the actual space between individual integrated circuit dies designed to accommodate the saw blade during the dicing process. Understanding these helps optimize wafer yield and ensures your manufacturing process minimizes damage to functional silicon areas.

Key Differences Between Scribe Line and Saw Street

Key differences between scribe line and saw street lie in their function and application within timber processing. The scribe line guides where wood is to be cut, ensuring precision before the actual cut is made, while the saw street indicates the space taken up by the saw blade during the cutting process, affecting the final product dimensions. Understanding these distinctions helps optimize your lumber yield and minimizes waste in woodworking projects.

When to Use Scribe Line Techniques

Scribe line techniques are essential when installing solid wood flooring or precise wood panels where seamless joints are required to accommodate irregular walls or surfaces. This method allows craftsmen to trace the contours of adjacent surfaces onto the flooring material for a perfect fit, reducing gaps and enhancing aesthetic appeal. Use scribe line techniques primarily in custom or high-end woodworking projects demanding precise alignment and professional finish quality.

Applications for Saw Street Methods

Saw Street methods are extensively employed in the semiconductor industry for precise dicing of silicon wafers into individual chips, ensuring clean and accurate separation with minimal material loss. These techniques are crucial in manufacturing microelectronic devices such as integrated circuits, MEMS, and sensors, where maintaining die quality and yield is paramount. The use of advanced saw street processes also supports high-throughput production lines by enabling rapid and consistent wafer singulation.

Precision and Accuracy: Scribe Line vs Saw Street

Scribe lines offer superior precision for marking exact cut locations on materials, ensuring consistent alignment and reducing errors during fabrication. Saw streets, being the actual cutting paths, can vary slightly due to blade thickness and technique, impacting overall accuracy. Utilizing scribe lines as guides improves dimensional control, minimizing deviations between design intent and finished product.

Tools Required for Scribe Line and Saw Street

Scribe line tasks primarily require precision marking tools such as scribers, rulers, and squares to ensure accurate measurement and layout before cutting. Saw street operations demand saws like circular saws or band saws, along with guide rails or fences to maintain straight, clean cuts. Your choice between scribe line and saw street should depend on the tools you have available and the level of precision your project requires.

Common Mistakes and How to Avoid Them

Common mistakes when working with scribe lines and saw streets include inaccurate alignment and improper spacing, which can lead to defective cuts and wasted materials. Ensuring precise measurement tools and consistent marking techniques helps maintain accuracy and reduces errors in both processes. Regular calibration of equipment and thorough training on scribe line and saw street standards are essential to avoid costly production delays.

Efficiency and Speed Comparison

Scribe line cutting offers high precision and clean edges, making it ideal for materials that require minimal finishing, which enhances overall workflow efficiency. Saw street cutting excels in speed when processing thicker or tougher materials, allowing faster throughput in production environments where time is critical. Your choice between scribe line and saw street should balance the need for accuracy versus cutting speed based on the specific material and production demands.

Tips for Achieving the Best Results

To achieve the best results when working with scribe lines versus saw streets, precise measurement and consistent marking along the scribe line ensure tight-fitting panels and minimal gaps in cabinetry or flooring installations. Using fine-toothed saw blades aligned exactly with the saw street reduces tear-out and promotes cleaner cuts in wood or laminate materials. Maintaining steady pressure and proper blade speed during cutting further enhances finish quality and durability of the final product.

Choosing the Right Method for Your Project

Choosing between scribe line and saw street methods depends on the precision and finish required for your project. Scribe lines offer flexible adjustments and are ideal for custom fits in flooring or tiling, enhancing accuracy in irregular spaces. Saw streets provide clean, consistent cuts suitable for mass production or large-scale installations, optimizing efficiency without compromising quality.

Scribe Line vs Saw Street Infographic

libmatt.com

libmatt.com