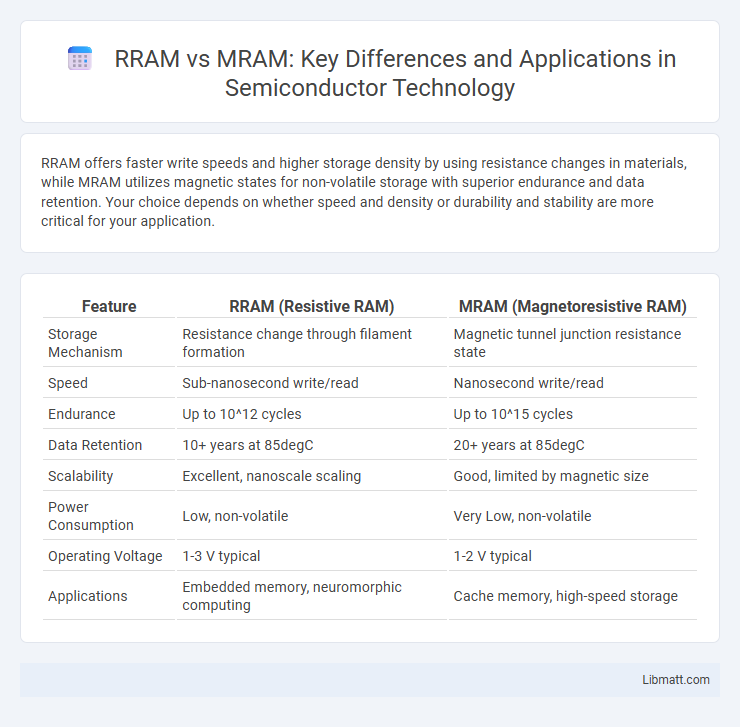

RRAM offers faster write speeds and higher storage density by using resistance changes in materials, while MRAM utilizes magnetic states for non-volatile storage with superior endurance and data retention. Your choice depends on whether speed and density or durability and stability are more critical for your application.

Table of Comparison

| Feature | RRAM (Resistive RAM) | MRAM (Magnetoresistive RAM) |

|---|---|---|

| Storage Mechanism | Resistance change through filament formation | Magnetic tunnel junction resistance state |

| Speed | Sub-nanosecond write/read | Nanosecond write/read |

| Endurance | Up to 10^12 cycles | Up to 10^15 cycles |

| Data Retention | 10+ years at 85degC | 20+ years at 85degC |

| Scalability | Excellent, nanoscale scaling | Good, limited by magnetic size |

| Power Consumption | Low, non-volatile | Very Low, non-volatile |

| Operating Voltage | 1-3 V typical | 1-2 V typical |

| Applications | Embedded memory, neuromorphic computing | Cache memory, high-speed storage |

Introduction to RRAM and MRAM

RRAM (Resistive Random-Access Memory) utilizes the resistance change of a material to store data, offering high speed, low power consumption, and excellent scalability for future memory technologies. MRAM (Magnetoresistive Random-Access Memory) exploits magnetic states to store information, providing non-volatility, fast read/write speeds, and superior endurance compared to traditional flash memory. Both RRAM and MRAM represent cutting-edge non-volatile memory solutions poised to revolutionize data storage with their distinct mechanisms and performance advantages.

Basic Operating Principles

RRAM (Resistive Random Access Memory) operates by changing the resistance across a dielectric solid-state material, utilizing the formation and rupture of conductive filaments to store data. MRAM (Magnetoresistive Random Access Memory) stores information by altering the magnetic orientation of ferromagnetic layers, relying on the tunneling magnetoresistance effect for reading data. Understanding these basic operating principles helps you choose the appropriate memory technology for specific applications requiring speed, endurance, or data retention.

Memory Structure and Design

RRAM (Resistive Random-Access Memory) utilizes a simple metal-insulator-metal (MIM) structure where resistance changes in the insulating layer store data, enabling high-density, scalable memory designs. MRAM (Magnetoresistive Random-Access Memory) relies on magnetic tunnel junctions (MTJs) composed of ferromagnetic layers separated by an insulating barrier, with data encoded through magnetic orientation states. The fundamental difference in memory structure--ionic drift for RRAM versus spintronics for MRAM--affects device endurance, switching speed, and integration complexity in embedded and standalone memory applications.

Performance Comparison

RRAM (Resistive Random Access Memory) offers faster write speeds and lower power consumption compared to MRAM (Magnetoresistive RAM), making it ideal for high-speed applications. MRAM excels in read speed and non-volatility, providing superior endurance and data retention under extreme conditions. Both technologies demonstrate significant performance advantages over traditional memory, but RRAM is typically favored for speed-sensitive tasks while MRAM leads in reliability and durability.

Power Consumption and Efficiency

RRAM (Resistive RAM) typically offers lower power consumption than MRAM (Magnetoresistive RAM) due to its simpler switching mechanism that requires less energy to change resistance states. MRAM provides high efficiency through non-volatility and fast read/write cycles, but its magnetic switching process can consume more power, especially in high-density applications. Your choice between RRAM and MRAM should consider the trade-off between RRAM's energy-efficient switching and MRAM's speed and endurance for optimal power management.

Scalability and Integration

RRAM offers superior scalability due to its simple metal-insulator-metal structure, enabling high-density arrays suitable for advanced node fabrication. MRAM, while highly reliable, faces challenges in scaling below 20 nm because of the magnetic tunnel junction's physical limitations. Integration-wise, RRAM's CMOS compatibility supports seamless embedding in various chip architectures, whereas MRAM requires more complex process adaptations, impacting overall manufacturing efficiency.

Durability and Endurance

RRAM (Resistive RAM) offers high endurance, typically supporting up to 10^12 write cycles, making it highly durable for frequent data rewriting applications. MRAM (Magnetoresistive RAM) exhibits exceptional durability with an endurance often exceeding 10^15 cycles, providing superior reliability for long-term data storage under extreme conditions. Choosing between RRAM and MRAM depends on your specific needs for write cycle intensity and environmental resilience.

Application Areas

RRAM is widely used in neuromorphic computing and artificial intelligence due to its high density and low power consumption, making it ideal for memory storage in edge devices and IoT applications. MRAM excels in applications requiring fast read/write speeds and high endurance, such as cache memory, embedded systems, and automotive electronics. Your choice between RRAM and MRAM should consider the specific application requirements for speed, endurance, and power efficiency.

Challenges and Limitations

RRAM faces challenges with endurance and variability due to filament formation inconsistencies, affecting device reliability and data retention. MRAM struggles with scalability and high write energy consumption, limiting its efficiency in large-scale memory arrays. Your choice between RRAM and MRAM should consider these limitations based on application-specific endurance, speed, and power requirements.

Future Prospects and Industry Trends

RRAM technology shows promising future prospects with faster switching speeds, lower power consumption, and higher density potential compared to MRAM, making it ideal for advanced memory applications and AI-driven devices. MRAM remains strong in the market due to its non-volatility, endurance, and compatibility with existing CMOS processes, which supports its adoption in automotive and IoT industries. Your choice between RRAM and MRAM will depend on specific application needs, with industry trends indicating growing investment in RRAM research and expanding MRAM deployment in embedded memory solutions.

RRAM vs MRAM Infographic

libmatt.com

libmatt.com